Quality monitoring of coating systems on steel and aluminum

Electrochemical Impedance Spectroscopy (EIS)

With his company Bjond Innovation, Jo van Montfort has made a name for himself in the field of inspection, research and advice regarding the life span and performance of building materials. This with a view to the safety of structures in concrete and steel. Regular or, better yet, permanent monitoring of the materials and their protective coating systems is of capital importance here. In recent years, Bjond Innovation is increasingly turning to innovative technologies such as EIS or Electrochemical Impedance Spectroscopy for this purpose.

Safety first

Steel is subject to corrosion, rust in the vernacular. Degradation of these materials can eventually negatively affect the structural stability of large building and infrastructure works. Apart from the sky-high repair costs, this also inevitably compromises the safety of occupants and/or users.

The life and reliability of materials can be significantly extended by applying targeted and protective coating systems. These require regular examination to see if their protective function has not diminished too much over time and to determine when maintenance or repair is needed. This measurement process is ideally controlled and carried out with remote sensors.

Holistic and non-destructive measurement method

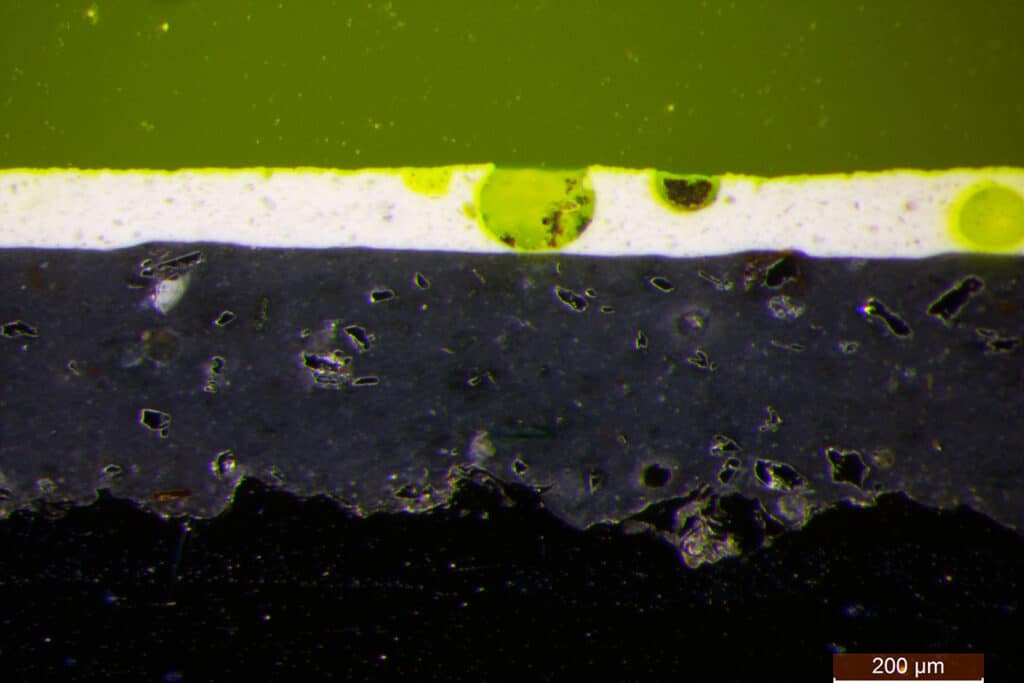

Coating systems on steel protect large building and infrastructure works from premature degradation due to weather or environmental influences and aggressive substances. In order to get a picture of the remaining expected life of a structure, the quality of the coatings and the inherent, necessary maintenance work, superficial visual inspections with destructive adhesion tests and/or sampling used to be used. This was a particularly time-consuming, thus expensive and at the same time destructive method that necessitated repair of the coatings thus damaged.

EIS combined with a holistic knowledge-based approach is an advanced non-destructive method and allows the entire preservation system to be mapped even remotely if necessary. This involves not only the quality of coatings, but also the substrate. EIS is also useful at an early stage to determine whether new coating layers were applied according to the rules of the art, which can save a lot of time and money later on. Thanks to c-cube international for the use of its advanced equipment.

Not only managers of large structures, including chemical plants, stadiums, lock complexes, windmills, bridges or steel facade structures benefit. The measurement system can be expanded with advanced camera techniques and also applied to homes and smaller apartment buildings to determine, for example, the quality of powder-coated aluminum building components. Is this still repairable or does it need to be replaced? This also helps in determining a correct resale value, for example.

Data-driven maintenance and repair strategy

Preventive monitoring using EIS provides a large amount of valuable data. On this basis, a maintenance and repair strategy can be worked out and this according to the customer's requirements. After all, the requirements are different when a structure has to last 50 or 100 years. In this context, Bjond Innovation recently entered into a partnership with Eindhoven-based BouwQ BV, which specializes in building inspections and quality assurance. Together, the companies are working on the development and refinement of a protocol that, based on the data obtained, should determine and describe the appropriate maintenance techniques.