Innovative detection equipment for lightning-fast and secure layer thickness measurement

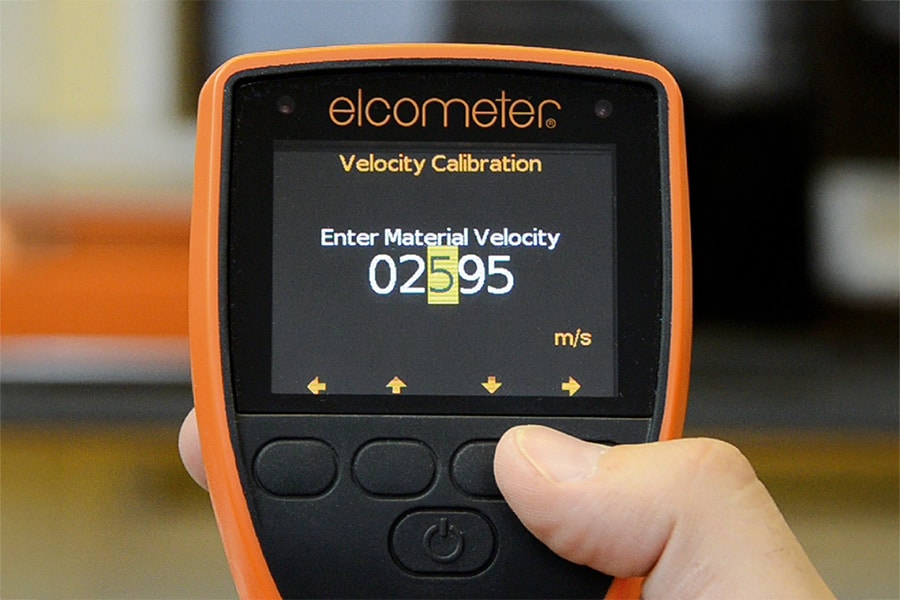

The technology to measure coating thickness on metal substrates without damaging the coating has been around since the first Elcometer instrument from the 1940s. However, until recently, it has been difficult to accurately measure coating thicknesses on concrete and other similar substrates in the same non-destructive manner. The Elcometer 500 Coating Thickness Gauge has changed this. The advanced device measures repeatable and reproducible dry film thicknesses of coatings on concrete. And that up to nine millimeters thick. Curious about this ingenious instrument, we spoke to Neil Beswick, who works at Elcometer as commercial projects manager and sales manager for the Netherlands and the United Kingdom.

Says Beswick, "In the construction and coatings industry, the ability to perform inspections quickly and efficiently is critical. Together with the free ElcoMaster® Data Management Software, this duo offers a combination of ease of use, speed and utmost accuracy. This allows inspectors to perform their work more efficiently while ensuring the quality of their measurements."

For more than 75 years, Elcometer has been a world leader in the design, manufacture and supply of inspection equipment for the coating, concrete and metal detection industries. It also supplies blasting and paint spraying equipment.

Speed

Inspectors spend up to thirty percent of their time generating reports. The combination of the Elcometer 500 and ElcoMaster means they can now quickly and easily generate professional reports and share them immediately with team members or customers. With over sixty readings per minute in standard mode and over 140 readings per minute in scan mode, the Elcometer 500 boasts impressive measurement speeds.

Cloud functionality allows real-time monitoring of inspections from different locations and production lines. This makes data always available and quickly shareable, improving overall efficiency. "In addition, inspectors can combine various inspection parameters, such as coating thickness, profile measurements, climate conditions and project-related information into a single report. This allows them to manage everything from a single platform. Because ElcoMaster® is compatible with multiple Elcometer instruments, companies can easily combine data from different instruments."

Data processing

The measurement data can be viewed on the meter, a mobile device or a personal computer. "The ability to automatically store large amounts of data is very useful for long-term projects and historical data tracking. The software includes the option to analyze data via histograms, statistics, graphs and photos, all of which can be easily included in reports generated through ElcoMaster®. This obviously enhances the visual presentation of the data."

Ergonomic and robust

The measuring probes are ergonomically designed: they require no force and are designed for long-term use. The tips are replaceable, so the probe itself is not damaged. This leads to long-term cost savings because only the tips need to be replaced. The device also indicates when the probe head needs to be replaced so that measurements can continue without interruptions. The signal strength indicator in turn ensures that the meter only displays reliable measurements when the signal strength is optimal.

The meter is IP54 certified, making it resistant to dust and water. This makes the Elcometer 500 suitable for use in harsh environments.