Modular construction, permanent quality

The advantages of modular construction are increasingly recognized in the traditionally traditional construction world. Modular construction means permanent quality, high speed and significant environmental savings, including up to 50% lower CO2 emissions. An interview with Daan Kosterman, project leader for circularity at Jan Snel, specialist in modular building concepts.

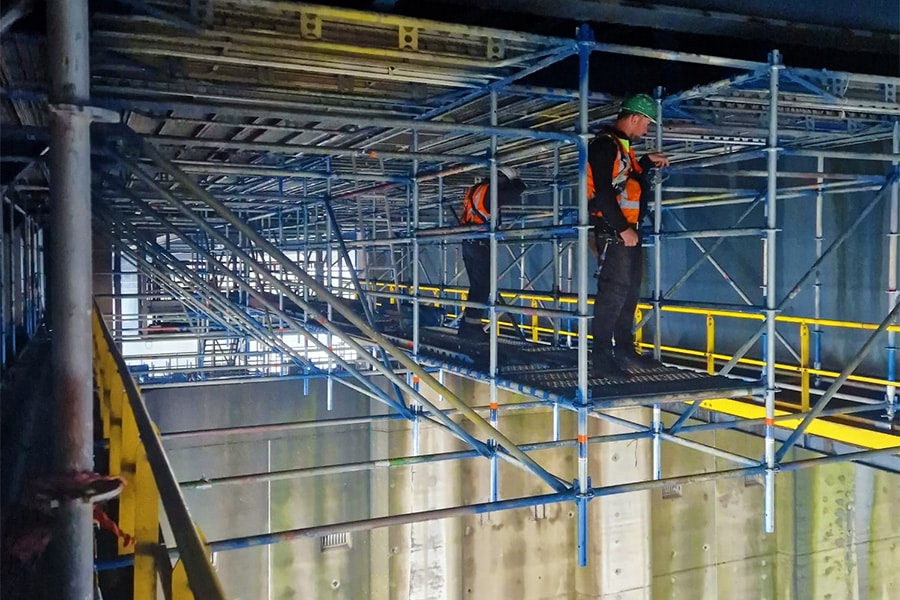

Text | Roel van Gils Image | Jan Snel

Modular construction is Jan Snel's specialty. With the modules, houses, schools, hotels, company buildings and even 'medical buildings' such as permanent operating rooms are realized turnkey. The modular modules are built at high speed on the site in Montfoort, a qualification that does not do justice to the end result.

Large-scale projects

"The first major step toward large-scale projects is the Ravel project in Amsterdam of several years ago," Kosterman said. "In just eleven months, we completed a completely new student housing facility for 800 students. Although the modular complex has a temporary use, it meets all the requirements of the Building Code for permanent housing. A very efficient solution to the housing shortage and an investment that quickly pays off. Jan Snel demonstrates this high construction speed time and again. For example, in Utrecht we built 400 student housing units in 25 weeks, in Maastricht 252 student housing units in 10 weeks and earlier we realized a housing complex with no less than 141 housing units for starters in Amsterdam within 13 weeks. The industrialized way of building makes us 30 to 50% faster than the traditional construction process."

Unique concept

Jan Snel's modules are characterized by steel frames, concrete (!) floors and a standard size of 6 by 3 meters. "The concrete floor in our modules makes our concept unique," Kosterman knows. "We use steel-fiber concrete for this. On the floor we build the steel frame that is filled in with HSB walls and ceiling. Depending on the destination, we can furnish the modules completely ex-factory as a complete studio, including bathroom and kitchen. On site, it is a matter of connecting and moving in. The first modules we produced thirty years ago still look good today. Our modules therefore have a very high reuse rate."

LCA

In 2019, Jan Snel expressed its ambition to eventually produce the modules in a fully circular way. "We have started to map out all the processes," Kosterman explains. "We use a relatively large amount of steel, but on the other hand, we take back and reuse almost all of our modules. Nevermind that we are in discussion with our steel suppliers about the origin of the steel. And so for all processes and materials we are looking at whether there might be more interesting alternatives, with the same properties but a lower environmental impact. Based on current LCAs, we made a comparison of a 6,000-square-meter building for 200 students, built from modular modules and traditional construction. What emerged? Modular construction saves up to 50% of CO2. This is largely due to the leaner construction and enormously lightweight concrete floors."

Modular construction thus brings great advantages. "We always build under conditioned conditions and the process is standardized. That ensures speed and permanently very high quality."