Quality products with short delivery time

D-Beton is putting the finishing touches to its brand new production site in Aalst, Belgium, which includes a covered concrete plant and a state-of-the-art production carousel. From the new production site, D-Beton can respond even faster to the growing demand for double walls, insulated double walls and wide slabs XL.

Text | Liliane Verwoolde Image | D-concrete

As a company, D-Beton is still young. Yet a wealth of knowledge and experience already exists within the company. "In fact, D-Beton is an extension of our family business, which has existed for three generations," says managing director Dominique Zyde. "When parent company De Doncker outgrew its size, we decided to introduce a new precast department under a new name. D-concrete is the specialist in concrete walls." In the fall of 2020, the new production facility will be ready for use.

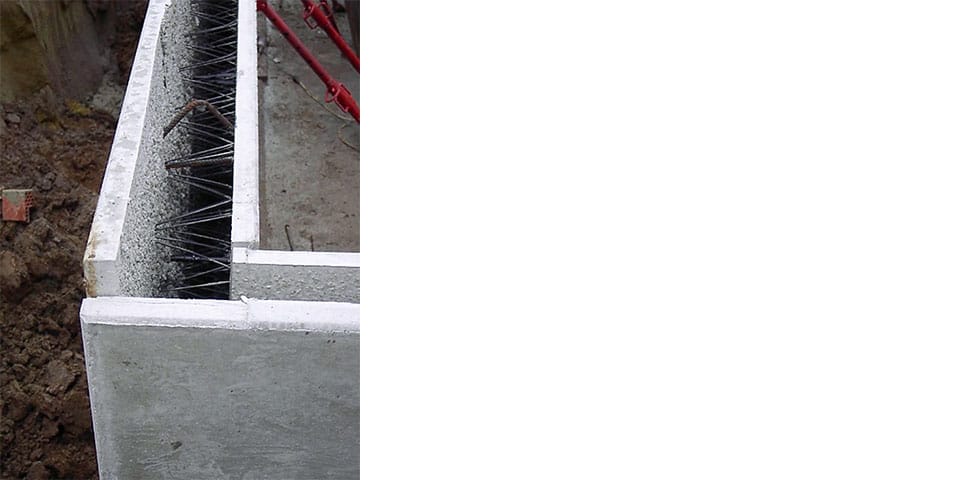

The double walls consist of two concrete slabs connected by lattice girders.

Accuracy guaranteed

The prefabricated carousel system in the new production facility meets the latest technical standards and is highly automated. "This also ensures accuracy," Zyde explains. "When orders come in, our draftsmen convert the customer's drawings into production drawings and a production file that can be read by the plant's production software. This file contains the dimensions for the formwork, the quantity and composition of the concrete and the reinforcement required. The high degree of automation of the production process virtually eliminates errors."

Of high quality

The new production line allows D-Beton to respond even faster and better to customer demand. "D-Beton's products are not new, but demand is high and thanks to the state-of-the-art production processes, all concrete walls are of high quality and KOMO, BENOR and CE certified. In addition, the lines of communication within the company are short, which also applies to delivery times." Meanwhile, the first orders have been placed. They are expected to be delivered in early 2021.