SPECIAL | Digitization increases productivity and reduces errors in precast concrete element production

The digitization of the industry continues to evolve, including in the production of precast concrete elements. Digital processes increase productivity and efficiency and reduce errors. For more than 30 years, Precast Software Engineering has supported its customers with industry know-how for production planning of precast concrete building elements. With SmartProduction (paperless production) and the IFC4precast data export, the specialist again introduces some innovative solutions for far-reaching digitalization of business processes.

Gone are the days when all production plans for precast concrete components were passed on paper. More and more companies are opting for extensive digitization of their production processes. "The digital and interactive handling of data significantly simplifies the distribution of data in the factory and thus contributes to a not-to-be-underestimated increase in efficiency on the shop floor. With the transition to paperless production, employees always have the most up-to-date plan at hand and can view everything in minute detail," says Susanne Schachinger, Area Sales Manager at Precast Software Engineering. "In close cooperation with other software houses and leading companies in the precast building element industry, we have been developing innovative software solutions for the optimization of production processes for more than 30 years."

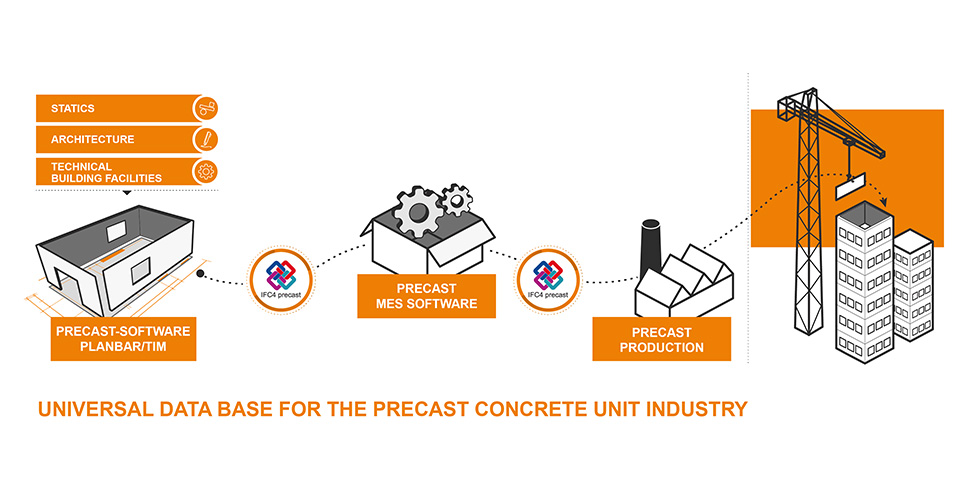

IFC4precast is a universal database for the precast concrete industry.

The paperless production or SmartProduction

For example, Precast Software Engineering and RIB SAA Software Engineering developed "SmartProduction," which means as much as paperless production. Together with some important players in the Austrian precast concrete industry, in particular Oberndörfer Betonwerke and Maba Fertigteilindustrie, the first reference projects have already been started. "In the past, when at the headquarters of Maba Fertigteilindustrie all information related to production planning was distributed on paper, the costs were considerably higher. During a year with 2,160 working hours, 840,000 A4 sheets were distributed. The time taken to prepare those plans, the printing costs and the ecological and sustainability rationale were important arguments for investing in SmartProduction," says the Area Sales Manager. "The company Obendorfer Betonwerke has also taken the step to paperless production and production plans at a test station are now projected with a beamer. The digital plan with all elements is displayed right in front of the operators on the wall, giving them all the necessary information for the production job at all times." At both firms, they are convinced that the digital distribution of plans is the ideal solution to continue to meet the increasingly complex challenges in the industry. The major advantage of SmartProduction is the automated distribution of technical plans to the various workshops. The presentation in the form of a roadmap allows complex elements to be divided into compact sub-plans. Thus, there are few questions and the number of errors is significantly reduced.

IFPC4precast data export

Under the auspices of BuildingSMART, the main partners from the precast concrete industry are now forming a working group to promote and facilitate the free dissemination of data within the sector. Entirely in the image of the OpenBIM principle, the interaction between different IT systems is to be significantly simplified. With the new data standard IFCprecast, interface problems are a thing of the past. "IFC4precast enables optimal interaction between CAD and MES systems on the one hand and the production plants on the other, reduces coordination and management costs throughout the entire process of planning, production and assembly, and allows unambiguous verifiability via the building model and the building cycle, and that in real time," Schachinger points out. "We are now the first CAD software developer to make available a complete IFC4precast data export via the TIM (Technical Information Manager)."