SPECIAL | More grip and fewer errors with IFC

Custom precast concrete element production is becoming more complex. Not only are the elements themselves becoming more complex, but delivery must also become increasingly just-in-time. The focus of the construction process is thus shifting from the building site to the factory. With the deployment of IFC, concrete producers can respond to this.

Whereas precast concrete elements used to consist only of concrete and reinforcement, we now see more and more components being incorporated into the element, says Bert-Jan Haarkamp of software supplier Profity. "The production of more complex elements requires careful preparation. Good use of design information in preparing for production prevents errors. Errors that not only cost money, but can also cause delays. The deployment of IFC will play an important role in ensuring the correct information is available." Industry Foundation Classes (IFC) is a neutral and open file format for exchanging and sharing specific BIM information (model objects and their properties) between the various software applications of parties in the construction process. IFC is independent, so no one is bound to a particular software package.

Turnaround times in construction must become shorter and shorter. "This requires more and more accuracy in planning and fewer errors in the delivery of precast concrete elements to the construction site. This is possible if production preparation improves. Here, too, the deployment of IFC can help."

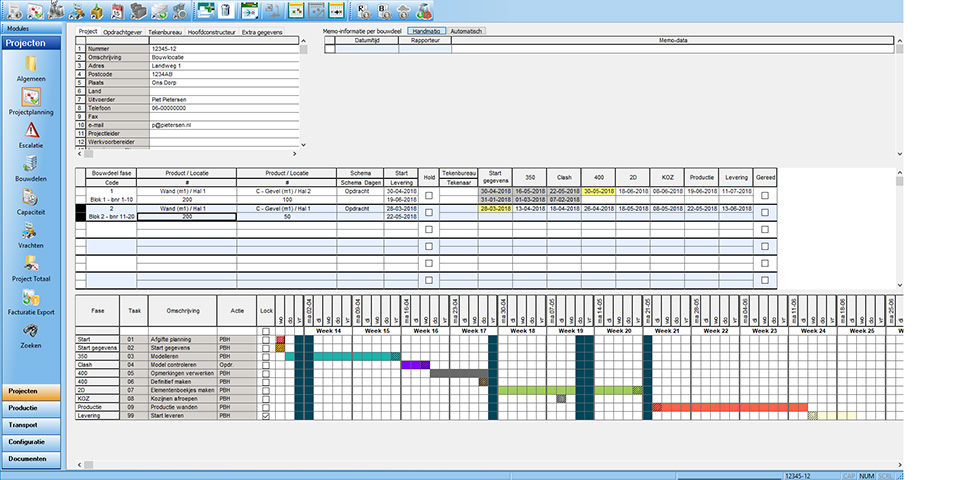

Profity Prefab is standard software for drawing room planning, production planning and freight planning of custom precast concrete elements. Haarkamp: "The input for planning almost always comes from a CAD package. Whereas in the past 2D information was supplied via, for example, Excel, exchange based on 3D information in IFC format is now increasingly used. Many precast concrete producers now work with a CAD package that supports 3D exchange of information based on the IFC format. These include Allplan, Tekla or Revit. This makes the planning process a lot less error-prone, more insightful and simpler. Also, design errors are traced faster. All relevant information in the drawing can be reused 1:1."

Whereas in the past 2D information was supplied via Excel, for example, exchange based on 3D information in IFC format is now increasingly being used.

Graphical planning of assembly sequence

The Profity Prefab viewer shows all elements per building layer. Then the assembly sequence can be indicated very easily. This forms the input for the freight and production planning. In all situations, the planner remains in control, but he is optimally provided with (graphical) information in his task.

Graphical scheduling of freights

Every element goes - preferably just-in-time - to the construction site. This requires optimization of the freights. With Profity Prefab, each element in a particular freight is planned. Here, thanks to the IFC information, information such as shape and weight, upstands or protruding frames can be used, so that each freight is not only optimized in terms of space and total weight, but also loaded in the right order so that the elements can be delivered to the construction site in the right order and at the right time.

Graphic planning of production

The delivery sequence is the input to production. The production sequence is determined by several factors, including the optimal use of table or runway area, the optimal combination and sequence of elements per table or runway, etc.. To support production, Profity Prefab can provide the appropriate production documents, again using the information from the linked CAD system.

Quality control

IFC information also comes in handy in quality control. A new development is the use of Mixed Reality. Using a tablet or AR glasses, the element to be produced can be projected onto the table or job using the IFC information so that formwork and pouring facilities can be placed correctly. Just before pouring, photos of the mixed information can be taken with the tablet or AR glasses: 3D projection and the actual placed formwork and pouring facilities. Thus, for each element before pouring, it is documented that the element has been constructed in accordance with the design. After production, photos can again be taken of the produced element in conjunction with the projected design.

Using the IFC exchange format provides major advantages, Haarkamp summarizes. "In addition, its possibilities are far from fully exploited, as the above shows. Profity Prefab makes grateful use of this. It provides its users with more grip and insight."