The power of simplicity: 'Constructing structures is child's play'

The different types of Wyli are beginning to find their way within the steel construction world. In 2013 came the Wyli Tension Disc, an elegant way to remove bulges from wind bracing. Recently this was joined by the Wyli Shockproof Disc for earthquake-resistant construction and a fitting system for cast-in-place concrete anchors. "A fourth type is currently being tested at TU-Delft, which should become a good alternative to injection bolts," said Erik Gerssen, director of Wyli Tension Disc.

The Wyli Tension Disc is doing well. Larger orders are now also coming in regularly, even from unfamiliar corners. "A number of steel companies have been working with it for some time; now you see the oil slick effect of word-of-mouth advertising," says Gerssen.

Leveling an angle line.

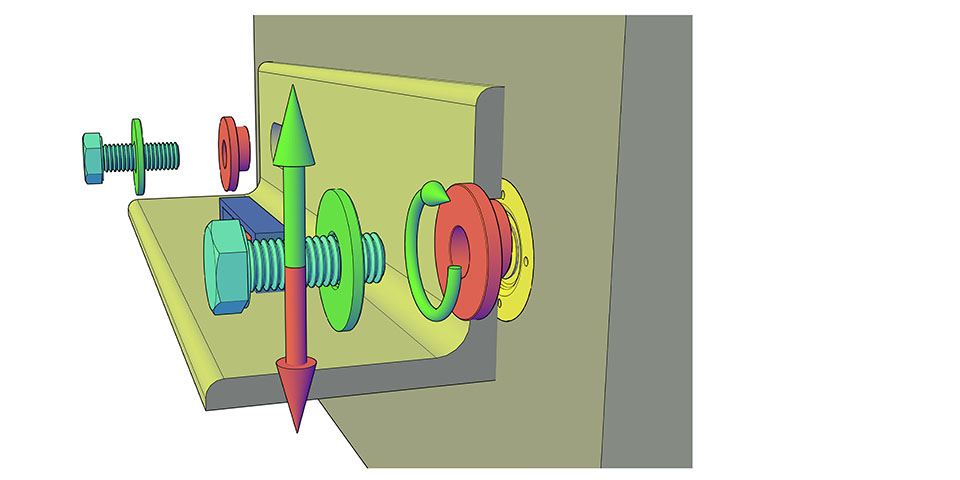

Eccentric adjusting ring

The patented system is a very simple, practical and inexpensive solution to a common problem. Gerssen: "In steel construction there are always things that can be improved, for example with wind bracing. Regularly there are some slack in a construction, while it should just be tight. As little as two to four millimeters are inaccurate. A layman can already see that this does not sit well. If this can be solved in a simple way, it has great added value. The trick of my solution lies in the eccentricity of the adjusting ring that allows you to adjust four millimeters back and four millimeters forward, eight millimeters in total. What you do with that is move the bolt hole. The adjusting ring has a hexagonal notch into which the bolt head falls. This allows you to use the same wrench you normally use to tighten the bandage. Two Wyli's can thus eliminate a 135 mm bulge on a six-meter strip. Separate tools are not required. Twenty years ago it was not possible to make such a ring for so little money. Today, a CNC lathe with automatic feed and removal does the trick. So we can offer the Wyli very cheaply." The Wyli Tension Disc is available in all common sizes, from M12 to M36 and for multiple sheet metal thicknesses. However, different sizes and material types are also no problem

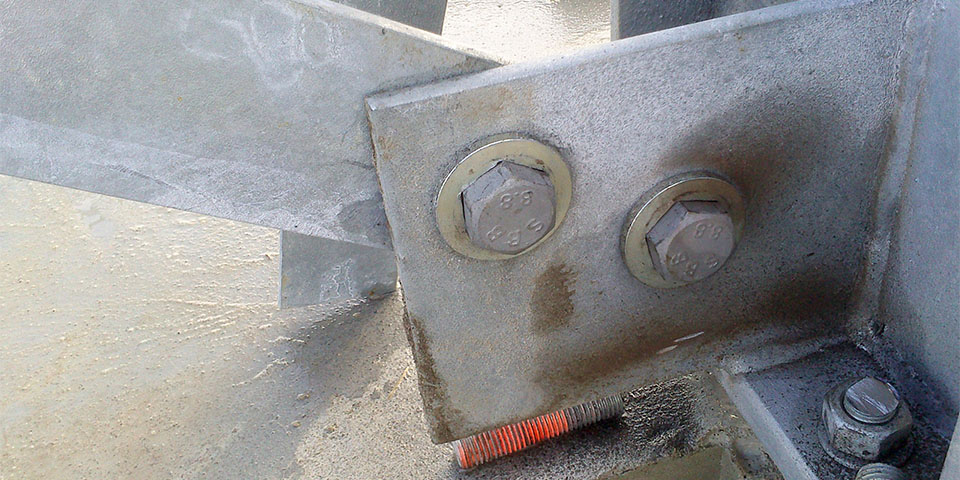

Wyli Tension Discs applied to a wind brace.

Earthquake-proof

A second type is the Wyli Shockproof Disc for earthquake-resistant construction, evolved from the Tension Disc. Gerssen explains: "In earthquake-resistant construction, very low tolerances apply; there may be minimal play in the junctions. You can solve that by welding it on site, but that is very labor-intensive. Fitting bolts are also a possibility, but have to be drilled in the work and that gives chips, thus rusting and other inconveniences. Injection bolts are also possible, but epoxy resin cannot be processed below a certain temperature and does not have the same compressive strength as steel. In addition, it is somewhat difficult to apply. Our solution is very simple: use two Wyli's opposite each other. This way you can reduce the gap from a maximum of 12 millimeters to just 0.1 millimeters, which is permitted for earthquake-resistant construction. We have now completed two constructions in Groningen with the Shockproof Disc to our complete satisfaction."

Level

A third elaboration of the adjusting ring principle is primarily used in precast concrete construction. "If steel is mounted to a precast concrete wall or concrete slab, wire sleeves are usually cast along with it. In practice, however, the tolerance is sometimes as much as 10 mm. A horizontal angle line for bearing, for example, therefore almost always hangs askew. With the help of Wyli's the angle line can be leveled easily and quickly," says Gerssen.