800 tons of new steel for Van Gendt Hallen

Storey floors and a 'buck' for a monument

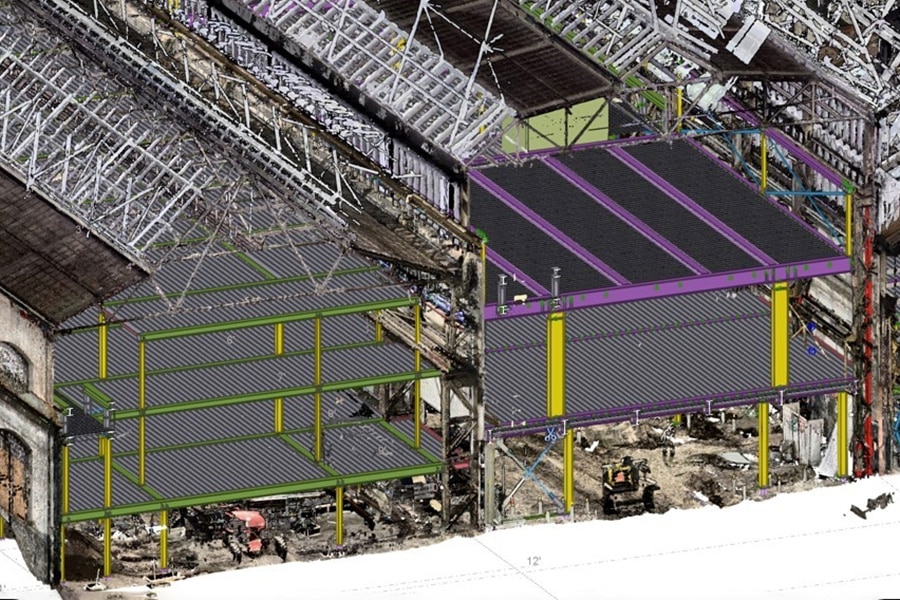

The transformation of the Van Gendt Halls involves a large amount of steelwork. For the variety of new functions that will come into the five halls, up to four new storey floors will be required per hall. Because of the monumental status and because the existing structure has little additional bearing capacity, each hall will have an impressive freestanding steel structure. In addition, owner Eduard Zanen wanted an inset port with an event space above it. For this purpose, a steel 'trestle' was built through the facade along the VOC quay on the Wittenburgervaart. Anything but a standard job and therefore an exquisite job for Vic Obdam Staalbouw.

"It was the project team Van Gendthallen BV that approached us to become a partner of the construction team and to think, calculate and build as a steel builder on the transformation of the Van Gendt Hallen," begins Rick de Keijser, director/project manager at Vic Obdam. "Not only the building is special, but also how the construction is organized can be called special. We do not work with a main contractor, but with the project team Van Gendthallen BV. And that is still going fantastic. The communication is excellent, everyone goes the extra mile when necessary and we are really working together on something very beautiful."

Task distribution

In November 2023, Vic Obdam started the engineering work, and around the 2024 construction period, the assembly of the first steel structure began. De Keijser: "We are working together with Sophia Engineering, which worked out the execution design of the monumental shell and also acts as structural engineer of the design by Braaksma & Roos Architects. We ourselves have extensive input into this from the VO phase, including detailed calculations and drafting the UO. Moreover, Vic Obdam took care of the main dimensions. Normally a larger contractor does this, but because we have extensive experience with this, the project team asked if we could take this on. A 3D scan of the entire complex was thus made with Total Station. This allows us to match the new steel structures - 800 tons in total - as closely as possible to the existing shell."

Floors

Most of this 800 tons of steel will be used to allow for storey floors in each hall. "The halls have different heights and will have different functions. For this, we are using robust steel structures to create two, three and four floors," De Keijser clarified. "This increases the original floor area of 13,300 m2 to 26,000 m2. The steel structures made of HEA sections stand on new foundations and reach up to 16 m high. The floors are made throughout with the same type of steel plate concrete floor from Tullingh & Partners, which we spray painted black on the underside for a uniform industrial look."

Bok

No less spectacular is the barge construction on the waterfront over the dock. De Keijser: "This docking facility is used for sustainable transport by water, specifically for loading and unloading goods and receiving future visitors to the complex. For this purpose, a dock has been created along the VOC-Kade and the facade has been partially cut open. This dock is covered with an event space that stands on four V-shaped legs. The legs become slimmer towards the top and are composed of steel plates with concealed welds so that this is aesthetically neat. At the bottom, the legs stand on a hinged shaft that rests momentarily on the concrete foundation. The event space will have a wooden floor and a roof of steel plate and insulation, around the facade we make a grid floor with safety line for the window cleaner. The connection of a roof truss of the existing hall to the roof of the trestle will be made with sliding plates so that the structures can move in a horizontal direction."

Vic Obdam is expected to finish construction of the floor floors in September and, in the meantime, is also building a steel bridge that will run right through the five halls. "Then we will have another appealing reference," De Keijser concludes. "Unique, complex projects with many challenges are simply right up our alley."