Digital transformation at UBAB: Greater efficiency in precast concrete industry thanks to software solutions

UBAB Ulricehamns Betong AB, a prominent player in the Swedish precast concrete industry, has embarked on a sweeping digitization journey with the implementation of Progress Group's ERPbos, aheadAPS and mebos software solutions. This initiative, driven by the need for efficiency and modernization, has revolutionized UBAB's operations and brought significant benefits in the various facets of its daily business.

Founded in 1990 with just six employees, UBAB has grown exponentially over the past few decades. Today, the company employs 410 people, reflecting its significant expansion and success in the precast concrete industry. This growth was made possible in part by strategic acquisitions. In 2012, UBAB acquired the plant in Dala and in 2020 that in Örs. Since January 2023, all three factories have been part of the CRH Group, supplying the whole of Scandinavia.

The three factories: UBAB, Örs and Dala

UBAB produces with three specialized plants: the UBAB plant produces a wide range of precast concrete elements, the Örs plant focuses on walls and retaining walls, and the Dala plant specializes in various floors and walls. Together, these plants cover almost every aspect of construction-related precast concrete products, with the exception of hollow-core slabs. This diversification allows UBAB to offer its customers a wide range of products.

The drive for digitization

The move toward digitization was made when UBAB hired a consulting firm to conduct a comprehensive inventory of its IT infrastructure. Extensive discussions with management and employees quickly revealed that digitization was essential to remain competitive in the industry and to meet the challenges facing the work. An advanced ERP system was identified as the foundation for this transformation.

Choosing the right ERP system

In 2021, UBAB conducted a detailed preliminary study to evaluate several off-the-shelf ERP systems. ERPbos from the Progress Group proved to be the most suitable choice because of its extensive capabilities and professional support. UBAB appreciated the Progress Group as a supplier because of its size, which guarantees long-term cooperation and the availability of technical consultants. In addition, the Progress Group offers a standardized system optimally adapted for use in the precast concrete industry, a clear roadmap for future developments and extensive testing at its own plant, making it an ideal partner for UBAB. Both plants, UBAB and Örs, use the Progress Group's software and the third plant, Dala, will start using it from 2025.

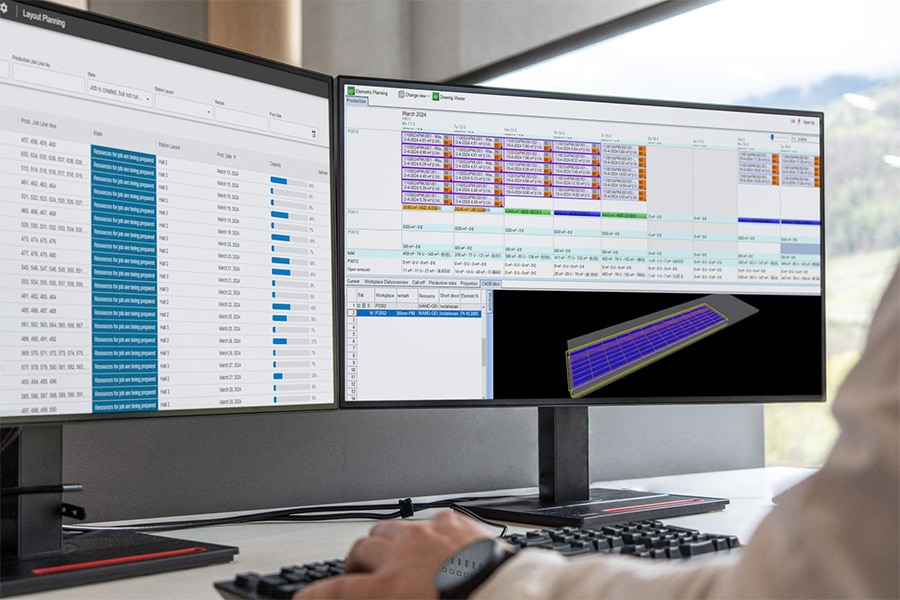

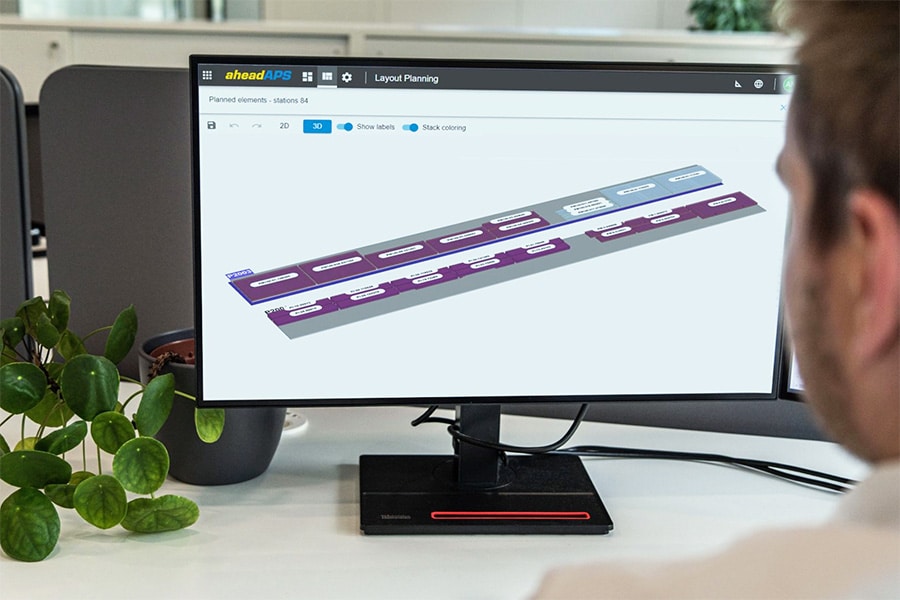

Optimization of runway production with aheadAPS

One of the biggest improvements was achieved with the introduction of aheadAPS software in the planning of runway production. Previously, this was done using AutoCAD, which made the process cumbersome and time-consuming. By switching to aheadAPS, UBAB streamlined the planning process, making it intuitive and rule-based. This not only simplifies the training of new employees, but also consolidates multiple systems into a single system, increasing efficiency and reducing both the potential for errors and the time it takes to prepare schedules.

Improved workflows through mobile integration

The integration of the mobile app mebos was a game changer for UBAB. mebos is used for storage, set-up, dump controls and production updates and provides real-time visibility into production status. This transparency allows management and supervisors to accurately monitor progress and address any issues quickly. The app also facilitates the management of defects, inventory adjustments, material returns and warehouse operations, significantly reducing paper usage and improving overall workflow. "The cooperation with the Progress Group during and after the implementation of ERPbos was very fruitful," says Marcus Nilson, IT Manager at UBAB Ulricehamns Betong AB. "Progress' consultants provided valuable insights, which enabled UBAB to find optimal solutions, even if it meant rethinking original approaches. The use of ERPbos in Progress' own factory ensured that many processes had already been tested, providing UBAB with a reliable and efficient system."

The digital transformation at UBAB has brought numerous benefits:

Increased efficiency: with ERPbos and aheadAPS, UBAB has streamlined its production planning and execution, reduced reliance on legacy systems and minimized manual activities.

Improved transparency: the mebos app provides real-time updates on production status, enabling better decision-making and faster response times.

Less paperwork: digital tools have replaced many of the paper processes, leading to more sustainable and efficient operations.

Improved training and ease of use: systems such as aheadAPS provide intuitive interfaces and rule-based guidelines, simplifying and shortening the training of new employees.

Comprehensive integration: ERPbos supports a wide range of processes, allowing UBAB to manage everything - from quotes to deliveries - in one system.

Outlook for the future

UBAB's digitization journey continues. Future plans include expanding the use of the mebos app for processing repair orders and digitizing packing slips. In addition, UBAB is pursuing full implementation of stack scheduling and other advanced features to further enhance its production capabilities. The implementation of ERPbos, aheadAPS and mebos is an important step in modernizing the operations of its precast plant. By embracing digital tools and processes, UBAB has positioned itself as an industry leader, ready to meet future challenges with increased efficiency, transparency and sustainability. Ongoing developments and future plans promise even greater improvements and ensure UBAB remains at the forefront of precast manufacturing technology.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met PROGRESS GROUP.

Contact opnemen

Contact opnemen