Temporary streetcar depot built with sustainability as first priority

In sixteen weeks, a streetcar depot was built on the edge of the Zuidas for historic streetcars from Amsterdam. It is a temporary facility related to the redevelopment of the Havenstraat area, where the depot has a permanent place. The City of Amsterdam asked for a circular solution for the hundred-meter-long depot. Steel builder Vic Obdam and contractor Witte Bouw realized this challenge in 16 weeks.

Streetcars have been an integral part of Amsterdam's streetscape since the 1910s. Many old streetcars still ride around and have their home at the Amsterdam Electric Museum Tramway near Haarlemmermeer Station. This Harbour Street site is undergoing large-scale redevelopment, including a new home for the museum tramway. Therefore, a temporary location was sought for the streetcars. One was found on the Zuidas at Jachthavenweg, where a temporary streetcar depot has been built over the existing track of the museum tram line.

Minimal environmental impact

The special project came to Witte Bouw through a tender from the City of Amsterdam. The contract consisted of a hundred-meter-long streetcar depot over a single track along Jachthavenweg. This contractor had engaged Vic Obdam for the steel structures. "Witte Bouw approached Vic Obdam because we stick our necks out in terms of sustainability," said Jan Smit, circular coordinator for the steel builder. "CO2 reduction was central to the tender and this is how we profile ourselves emphatically. This is a temporary project, so you want as little environmental impact as possible."

XCarb steel

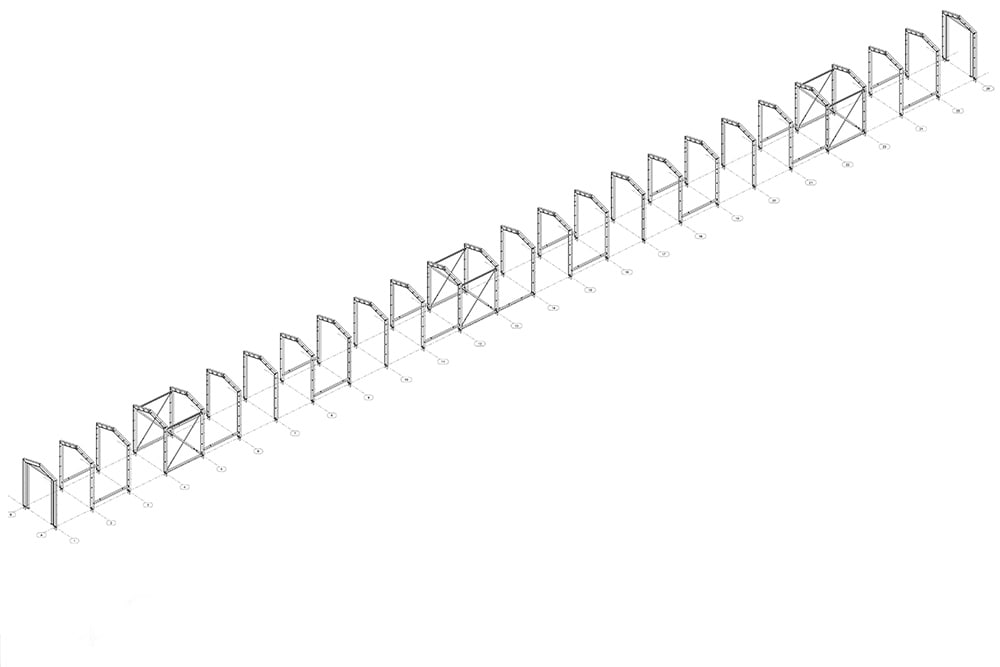

The elongated structure is elaborated with a gable roof and constructed of steel portals with an exterior cladding of residual material from the steel industry. "To keep the environmental impact minimal, the most beautiful solution is, of course, to work entirely with donor steel," Smit states. "But the short schedule made it impossible to find donor material; we know from experience that a lot of time goes into that. We do know how to produce new steel as sustainably as possible. ArcelorMittal makes XCarb, steel made in an electric furnace with green electricity and with a minimum of 95% scrap. This includes a CO2 reduction of sixty percent. From this XCarb steel we produced the 26 steel portals. The depot must stand for five years, which partly determines the finish of the steel. Coating or galvanizing is then not a sustainable solution. We ended up with just a biobased primer from Baril Coatings, quite appropriately in a green color."

Leftover plates

The unusual facade finish is an invention of architect Bureau van Eig. "Green-painted wooden plate facades form the basis of an outer shell of contour plates, residual plates from the metal industry. These CNC cut sheets are screwed untreated to the wooden walls and will soon form a combination with the green walls and portals that fits nicely into the leafy surroundings. A total of 102 plates were used. With the different sizes and many cut shapes, that was quite a puzzle."

The project was completed in a very short time. Smit concludes, "In mid-April of this year, the first pile was constructed on which the portals stand. In August, the first streetcar could already shelter under the roof. Still, a nice sustainable work that we have put up on the Zuidas."