dronryp bridge | Energy-neutral bridge forms new gateway to Dronryp

Commissioned by the Province of Fryslân, contractor Koninklijke Oosterhof Holman delivered the new bridge over the Van Harinxmakanaal in the village of Dronryp at the end of June. Constructed entirely in steel and resting on a concrete foundation, the eye-catcher replaces the previous 75-year-old bridge that was in poor condition. The maintenance-free and at the same time energy-neutral bridge has a passage width of 17 meters for the movable part and a passage height of 5.5 meters. This allows larger barges to also use the waterway and keeps the village optimally accessible.

Active in the versatile market of earthworks, civil engineering and environmental engineering, Koninklijke Oosterhof Holman of Grijpskerk is the perfect party to successfully implement the project in Dronryp. "During the design of the bridge, innovation was the key word," says project manager Wijbrand Attema on behalf of the total solution provider. "Where the realization of such a structure normally takes about a year, we managed to reduce the construction time to seven months through smart and innovative actions. The modular construction of the bridge contributed greatly to this. The bridge elements were made in the steelworks and assembled at the construction site like Lego bricks. An approach that offered the necessary advantages: we had more control over the construction process and were less dependent on weather conditions. In addition, there was less construction nuisance for the surrounding area. The steel bridge sections, for example, were installed in just three nights."

The motion work and ballast box are visible from land and water.

Energy efficient

The focus on the latest developments in terms of energy and materialization has led to a great result in Dronryp. For example, the materials of the old bridge have been completely recycled. The new bridge is completely maintenance-free and energy-neutral. Thanks to smart solutions in the design, the bridge's power consumption has been reduced to the minimum. "Approximately 2,800 kWh is needed to open the movable part of the bridge," said Attema. "The electromechanical main drive requires 50 percent less energy than regular systems."

Sustainability central

Province of Fryslân as client is clearly delighted when the cooperation with the various construction partners comes up for discussion. This is evident from the words of Hotze Brouwer, Infraprojecten project manager on behalf of Province of Fryslân. "Together with main contractor Oosterhof Holman, architect IPV Delft and all partners, we focused sharply on cooperation, sustainability and innovation during this project. That has produced a wonderful end result."

The steel bridge was made in record time at three locations: the piers at Machinefabriek Rusthoven BV in Groningen, the halyard at Solidd Steel Structures in Sumar and the abutments at Hillebrand Steel Construction in Middelburg. "Great to see that, thanks to an innovative construction process and good cooperation, the parts fit together exactly when they were assembled in Dronryp," Brouwer reflects.

The innovative low-noise joint transitions have a service life of as much as 100 years.

Unique design

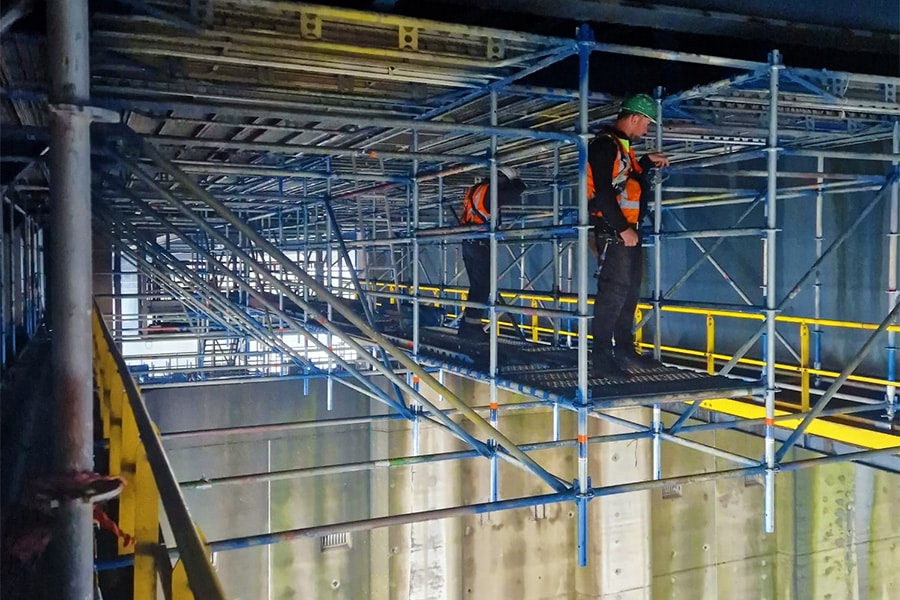

A characteristic feature of the bridge is that the piers stand on either side of the slender continuous bridge deck and the overlays are integrated into it. Because of the openness, there is an unobstructed view under the bridge, so that the movement and ballast box can be seen from land and water. The pillars narrowing in appearance emphasize the landscape transition from village to countryside.

Upper deck installations are integrated as much as possible into multifunctional vertical elements with lighting, cameras, locking trees and a weather station. This creates a calm image. The switch boxes are incorporated into the steel bridge piers, eliminating the need to build a separate space. The new bridge is operated remotely from the Swettehus in Leeuwarden.