Prestressing system 'preserves' monumental lock keeper's house

The Albert Canal in the Port of Antwerp is being renewed and adapted to the ever larger size of barges. As part of this, the Royers Lock is also receiving a comprehensive update and is being substantially expanded. To preserve the history of the area, the striking lock master's house from 1907 is being renovated and put into use to operate the new lock. DYWIDAG was engaged to use a temporary pre-tensioning system to hold the dwelling in place during the excavation work.

In the design that architectural firm ZJA made for the new Royers Lock, much attention was paid to combining the historical components and the new elements to be built. "With the expansion of the lock, the lock master's house will be located on an island, so to speak," begins Robert Jansen of DYWIDAG. "All around the building is being excavated to a great depth. Before that happens, the lock master house will first be placed all around in the diaphragm walls. To prevent the diaphragm wall from 'falling out' after excavation, we make sure that we anchor the diaphragm walls with each other at the top, right through the house, using our pre-tensioning systems."

Tense and relaxed

The diaphragm walls will be installed to a depth of 21 meters after which the soil package will be excavated about 15 meters. "The house is on piles, so there is no chance of it sinking," says Jansen. "However, it is important to keep the soil package around the piles stable. That's why we chose to set the building in diaphragm walls all around. The walls are placed in the ground with considerable overlength, but there is no anchoring at the top. We solve that with our pre-tensioning system. We have developed a concept that can not only absorb the forces, but can also be relaxed and removed after about three to four years."

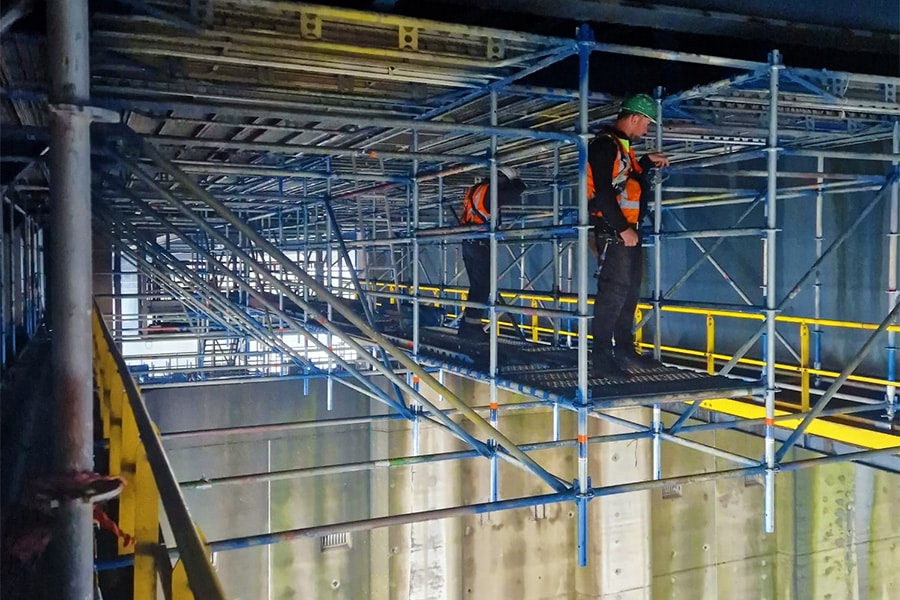

The basis is formed by a 15-strand prestressing system from DYWIDAG containing fat strands in a PE casing. "A structural concrete beam is placed on the diaphragm wall into which our anchorage is incorporated and we can tighten and relax the whole thing."

Distortion

In total, DYWIDAG is installing eight prestressing systems longitudinally and five across the building. "The strands go right through the basement of the lock master house," Jansen explains. "We deliberately tension at a very low prestressing force and rely on the mechanism of deformation. Because the diaphragm wall is going to 'bulge' by its own weight anyway, the cable will automatically come under tension. Once the work is completed, the soil will be backfilled and the diaphragm wall construction will bend back inward a bit, relaxing the cable slightly. The expectation is that the structure will not assume its original position, which is why we need to relax the prestressing systems in the final phase."

The prestressing structure at the lock master house is not technically very complex for DYWIDAG. Jansen: "The spans and cable construction are fairly standard; it is precisely the application that makes the project special for us. With the addition that we get to relax the whole thing after a number of years. Such a temporary application is not very common for our systems and makes it quite unique."