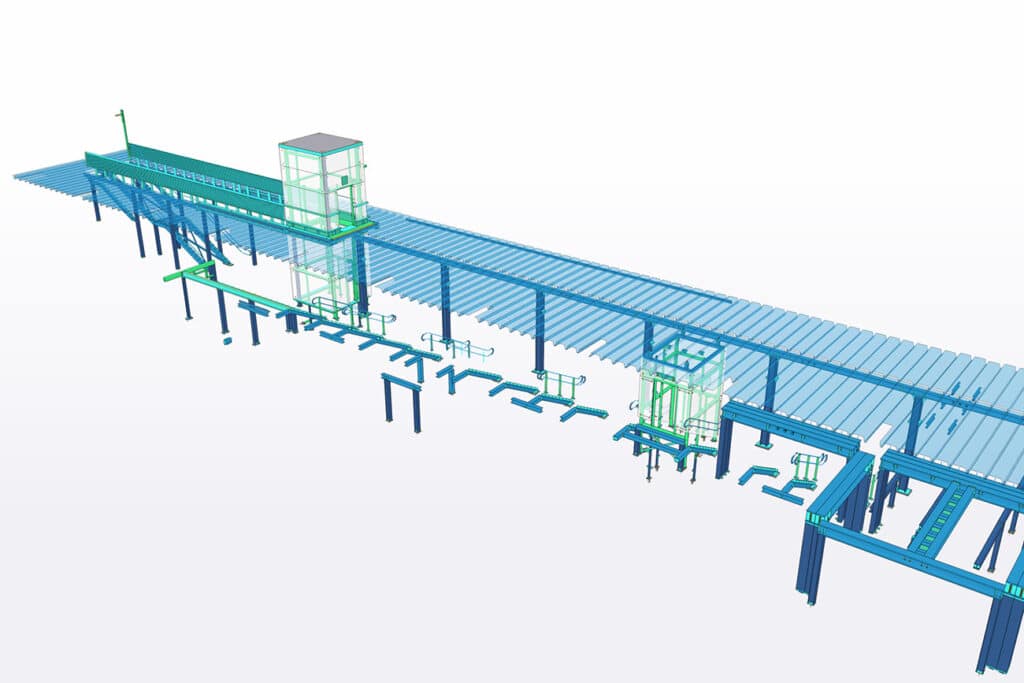

Auxiliary structures for widening tunnel and platform

Renovation Central Station Amsterdam

Amsterdam's Central Station is getting more and more trains and passengers. ProRail expects around 275,000 passengers a day in 2030, compared to 200,000 now, and that means correspondingly more trains will be using the station. That is why the monumental station is being thoroughly renovated over ten years. Besides adjusting and renewing the rail infrastructure (tracks, bridges, switches, signals and catenaries), the platforms will be made wider and longer, the building renovated, the pedestrian tunnel widened and the western entrance improved. Civil Techniques deBoer, as a specialist in jacking, support structures and final steelwork, has been engaged in the conversion of platform 1.

"It's definitely a challenging work environment," says Assistant Project Manager Joeri Verhoeven of Civil Engineering deBoer. "We have to take into account passengers, train traffic and work mostly in confined spaces. In addition, the station is located on an island, so a lot of transport is via the railroad or via the north side of the station. Not to mention the structures themselves, which date from 1912. Then you sometimes get surprises when you remove a ceiling, for example. In that respect we are now taking a nice step forward. Everything has been worked out in BIM based on a coordination model with input from new scans. We draw in our auxiliary works and the final steelwork based on this data so that interfaces can be controlled as much as possible at an early stage."

Auxiliary structures

Civil Techniques deBoer is collaborating on the approach to the western entrance and platform 1. The passenger tunnel will be widened, as will the platforms, and additional elevators will be installed. Verhoeven: "We are providing all the auxiliary structures needed to support the structures above during demolition work. For the first phase, we started work on platforms 1 and 2A at the end of last year; these platforms should reopen around the summer. Our auxiliary structures, recognizable by the blue color, ensure that the monumental superstructures remain intact so that demolition work can be carried out below them. To avoid cracking in the superstructure, the steel girders of the auxiliary structure have been tensioned. Fiber optic sensors monitor whether the monumental facades remain stable."

Sizing

Beams, columns and jacks are used for the support structures, which are up to five meters wide. Verhoeven: "The weight of the superstructures was determined beforehand with the structural engineer, and the support and jacking force required were dimensioned accordingly. Not too heavy and certainly not too light. Amovatiebedrijf Aalsmeer was then able to carry out the demolition work. Then the new steel girders from Rijnstaal Nieuwegein were put in place and we were able to remove the auxiliary work. Soon an important phase will start in which we will assemble the new steelwork for the platform, including Comflor cladding."

Sustainability usually has a prominent role at ProRail in tenders. "This client has an eye for that," Verhoeven confirms. "We are therefore working with emission-free equipment in this project. That is an important point of attention at Civiele Technieken deBoer. Moreover, it's no fun working in confined spaces with machines that produce exhaust fumes, so the choice was quickly made here."