Securing the future through automation and software in Norway

In the future, the demand for efficient and sustainable processes in the construction industry with high levels of automation and digitization will continue to grow. Prefabrication is well placed to meet this demand. It is an efficient and high-quality method of construction, and Overhalla Betongbygg is convinced that prefabricated parts will be in high demand in the future. That is why Norway's most modern manufacturer has invested in automated reinforcement machines and innovative software from one of the market leaders in precast technology: the Progress Group, in close cooperation with its renowned Danish partner CPT.

The effects of automation

Overhalla Betongbygg is already seeing the results of its investment in the new M-System Blue-Mesh® mesh welding machine with accompanying software solution. It has managed to reduce its steel consumption by 20% and produce with lower raw material consumption and higher quality. The new net welding machine produces not only flat reinforcement nets, but also fully bent reinforcement baskets. The use of so-called single bending heads is unique in Scandinavia. The purchased machines have also led to a significant improvement in working conditions and less physically demanding tasks.

The benefits of software integration

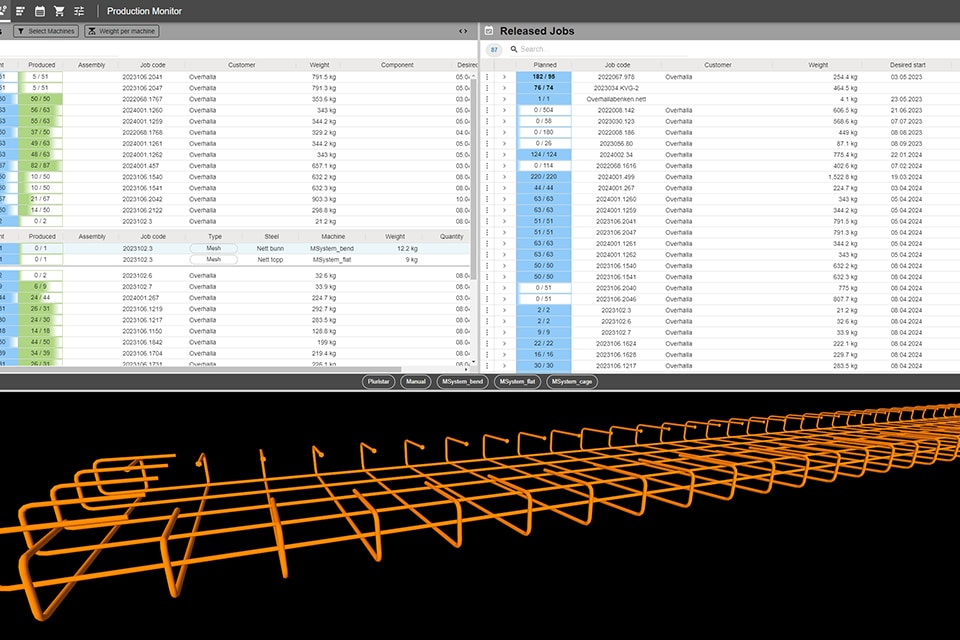

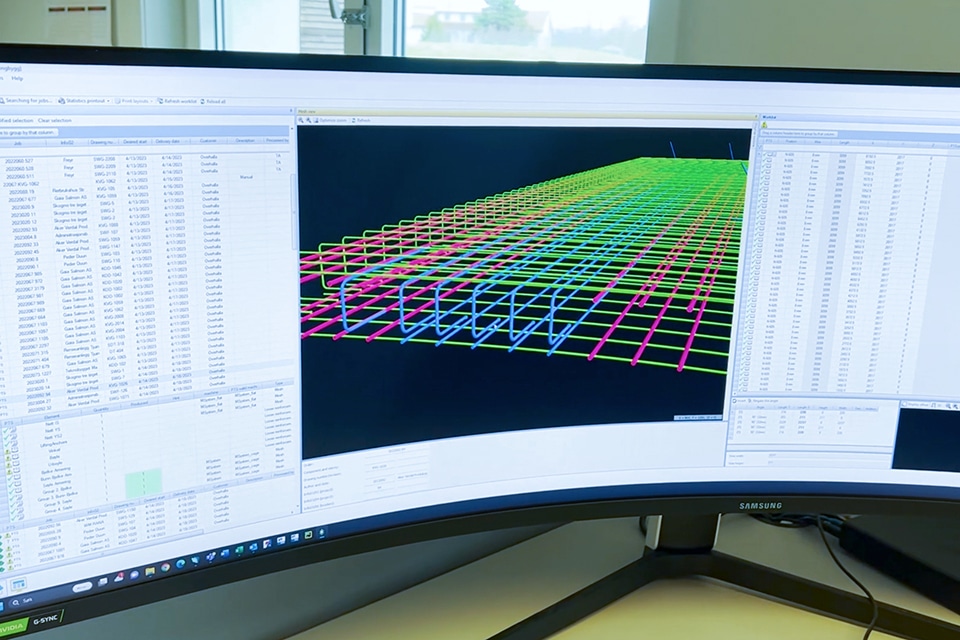

Progress Group's implemented software solution allows Overhalla to import CAD data, modify it and then, in combination with the ERP system, control production. The software "profit" is a customized solution for the management and the organization. With this software, production processes, orders and the machines themselves can be monitored and controlled. The software package also includes the 'stabos' solution for collecting and evaluating machine and production data. Thanks to the centrally collected data, it is easy to monitor the productivity, efficiency and quality of the machines and react immediately to machine downtime. The unique cloud service also allows data to be accessed from anywhere.

Modern methods for a better future

Overhalla also changed its way of working in production to optimize machine performance and efficiency. This significant investment has made the company more competitive and sustainable. Moving from the traditional way of manufacturing to a more machine and automated production has been a big step. "Our designers have learned new ways of designing, with a greater focus on optimization in sizing. We are satisfied with the investments we have made so far," says project leader Odd Andre Devik Amdal, adding, "The cooperation with Progress Group was good and this both before the investment, during implementation, and also after installation."

Leading concrete element factory

Overhalla Betongbygg was founded in 1946 and has been a supplier of concrete products ever since. Over the past 30 years, the company has experienced great growth in the precast concrete industry. Today, the company is the leading concrete element factory in Norway, especially in digitalization and automation. Overhalla Betongbygg's market extends across the country and the company supplies a wide range, from commercial buildings, bridges and monumental buildings to large smolt plants (salmon farms), which is its specialty. Currently, the company is building the government quarter in Norway's capital, Oslo.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met PROGRESS GROUP.

Contact opnemen

Contact opnemen