With its many favorable properties, basalt fiber has a future in construction

Basalt fiber is a special raw material with a laundry list of possible applications. This material is also increasingly used in construction as reinforcement in concrete and in bar form to strengthen existing structures. Because it is non-conductive, it is already being used in floors for automatic transport and in operating rooms. A very special application is the renewal of the hundreds of meters long artwork Sea Level by Richard Serra. With basalt fiber and blended macro fibers, this fragile construction can withstand rough handling for a very long time.

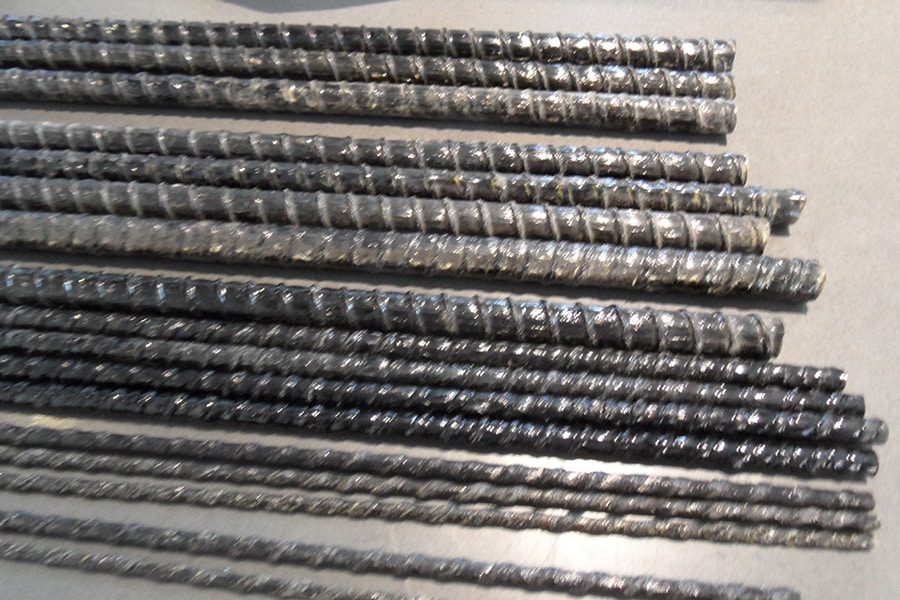

Basalt fiber is created by pulverizing basalt rock and then melting it at 1,400°C. Through extrusion, threads with a diameter of 9 to 13 micrometers are drawn from the molten material. This process has existed for a hundred years. Basalt fibers can serve as aggregate for concrete, rope can be made from it, and with the addition of epoxy resin, it can be made into reinforcement rods. Because of a whole set of favorable properties, it finds application mainly in industry, and recently construction is also beginning to take notice of this material.

100% recyclable

Hans de Wit, owner of Vulkan Europe BV of Gouda, has been working with basalt fibers for decades and welcomes the increased attention to the natural product. "The tensile strength is two and a half times that of steel and the product is resistant to high temperatures, does not conduct electricity and it is highly resistant to chemical and corrosive influences. As for the latter, with the major replacement and renovation task we face with infrastructure, chloride-resistant reinforcement is obviously not a bad idea. And basalt fibers are a natural product that is completely circular as a reinforcement material. The small amount of epoxy resin in the reinforcement bars is so low that you can call this concrete 100% recyclable."

Noise barriers and fire walls

With these useful properties, the applications are there for the taking. De Wit: "The fact that it does not conduct electricity has already led to interesting projects such as the runway with self-driving container transport on the Maasvlakte. The prefabricated firewall panels of the Breda bus depot contain basalt fiber reinforcement, which not only means a considerably lower environmental impact on the reinforcement, but also a wall that can withstand high temperatures. And recently six kilometers of noise barriers along the A10 North were replaced with screens with basalt fiber reinforcement."

Amsterdam quays

Reinforcing bars are also increasingly finding their way into the renovation and restoration sector. De Wit: "BAM recently reinforced the walls of a castle in Maastricht with these rods. Anchors had to be inserted from above. Drilling is obviously done with water, but if you do that with a basalt rod and mortar, it will never, ever rust. You can also use it to replace a steel lintel by mixing basalt fiber into the grout and/or masonry a rebar into the grout. And people are now also reinforcing weakened quays in Amsterdam, a huge problem. As one of the chosen few, we have been allowed to carry out pilot projects and reinforce the quays with beam frames that will make them last another 25 years. That gives the municipality time to deal with the real emergencies elsewhere."

Sea Level

The most beautiful renovation is currently being completed in the polder near Zeewolde. De Wit: "Sea Level is an extraordinary work of art by the world-famous artist Richard Serra, who sadly passed away in March this year. It consists of two diagonally aligned walls 200 meters long and three and a half to one half meters high. The walls, only 25 centimeters thick, were in poor condition and are being completely replaced with basalt reinforced concrete walls, giving it a relatively low carbon footprint. To make this thin wall sufficiently resistant to transverse forces, a macro basalt fiber of 4.8 cm was added. Sea Level is now excellently protected against corrosion and other deterioration by the basalt reinforcement."