Control over and grip on time

Hours are the big uncertain factor

In project-based steel construction, time is the most important driver of your profitability. In fact, hours are the major uncertain factor. They are also the most difficult to estimate. When you have control over them, you get peace of mind in your business. Speaking is Niels Oudenaarden, commercial director of Liemar.

"Hardly anyone really dares say it, but what I gather from conversations with project-based steel fabricators is that they don't know exactly how many hours they actually spend on a project," says Oudenaarden. "Without good 'help,' that's also pretty hard to estimate. Often schedules are made but not properly adhered to. Extra work, unexpected bottlenecks and last-minute changes cause a structural overrun of the expected hours. What seemed profitable in the calculation changes as the project progresses, with the result that the margin evaporates. Not because of bad orders, but because of lack of grip."

Efficiency

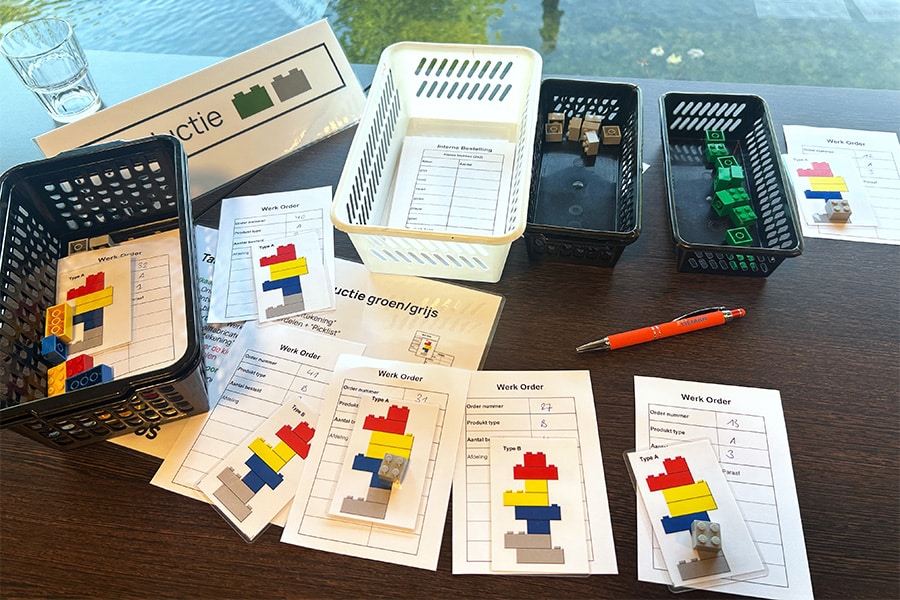

Liemar helps project-based steel and metal construction companies organize, plan and coordinate their projects efficiently. They do this with the help of specifically developed tools. This way you get a grip and reduce costs and lead time, while increasing quality and efficiency. According to Oudenaarden, you have to make software work for you. "As an organization, you must not be a slave to your systems, but really start using them. Many steel fabricators are mainly retyping lists. That's because they are not well organized." And that's exactly where the pain is. "Many companies run into the same frustrations: the feeling of constantly being behind the times, the pressure of ad hoc solutions and the endless shuffling of schedules. Often it starts with seemingly simple tools that work independently. But precisely because work is not integrated, the whole thing becomes unnecessarily complex. Not because the work is too much, but because there is no grip on time, capacity and overview. That causes irritation on the shop floor as well as at the desk - and it doesn't have to stay that way."

Time is not just about the number of hours worked on something. It touches on everything from lead time to peak load and from capacity planning to delivery pressure. "Without insight into your capacity, you never really know if your planning is realistic," Oudenaarden explains. "And then you get into a jam every time. Not because you can't handle the work, but because you haven't allocated it properly. Time is broader than hours - it's the common thread of your entire operation."

Business perspective

Because Liemar focuses purely on steel construction and looks into the kitchen of many companies, it often knows where the shoe pinches. "We look at our customers' processes from a business perspective and structure them from top to bottom. If you do it the other way around, from the bottom to the top, you start 'tying' all kinds of systems together and you are by definition reactive. There is then no steering," Oudenaarden explains. "You then get a landscape full of islands of information, where each island thinks it is the mainland. Nobody oversees the whole anymore. By applying structure from top to bottom, you really make a difference, because you get control over and grip on time."

Work in progress as a steering tool

An important part of that steering is Work in Progress (OHW), Oudenaarden says. "With many companies, OHW is still a snapshot for the administration, while it is actually your most important steering instrument. It shows exactly how your projects are doing, how much you have already realized and what is still to come. If you monitor this in real time, you can make adjustments much faster. And that makes the difference between delivering on time with a margin or having to explain afterwards where the profit went."

Always accessible

"A good welding machine doesn't make you a good welder," says Oudenaarden. "That also applies to software, and we understand that like no other. We obviously take care of the complete implementation process and the necessary education and training, but users can also come to us afterwards with questions. We can 'just' be reached by phone and do not use a ticket system for the helpdesk. It is precisely through that personal contact that we often find out the underlying or deeper question someone is trying to ask. That is crucial and ultimately pays for itself. After all, we too benefit from satisfied users." And satisfied users Liemar has in abundance. Indeed, most customers act as true ambassadors. According to Oudenaarden, it is also due to the fact that Liemar focuses exclusively on one niche. "We are not generalists, our software reasons purely from steel. Liemar is much more than planning software, it provides control over and grip on time."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Liemar Software BV.

Contact opnemen

Contact opnemen