Smart use of software and machine automation

Revolution in precast concrete production

By opting for software solutions and machine automation, Lammers Beton has profiled itself as an innovator in precast concrete production. Since its founding in 1987, Lammers Beton has grown into a company with three production locations in Weert, employing over 235 professionals. The company specializes in complex and architecturally challenging concrete elements such as facades, balcony and gallery slabs and building elements and primarily serves contractors who rely on its expertise when it comes to high-quality precast concrete products. This article highlights the impact of software integration and automated machinery on Lammers Beton's operations and efficiency.

Investing in software

A crucial moment for Lammers Beton was the introduction of Progress Group's profit software, which currently has six active users with plans for further expansion. The software is primarily used in the in-house reinforcing plant and offers capabilities such as production tracking and workload mapping, significantly improving the planning and production process. Initially underestimated, the software quickly proved invaluable for generating accurate rebar net data and improving production efficiency.

Hein Moors, 3D Process Engineer at Lammers Beton, looks back on the initial skepticism and subsequent awareness: "In the beginning I thought we wouldn't use it much. That was a big mistake. The capabilities of the software became clear when we started using it on a large scale to streamline our processes."

The choice of automation

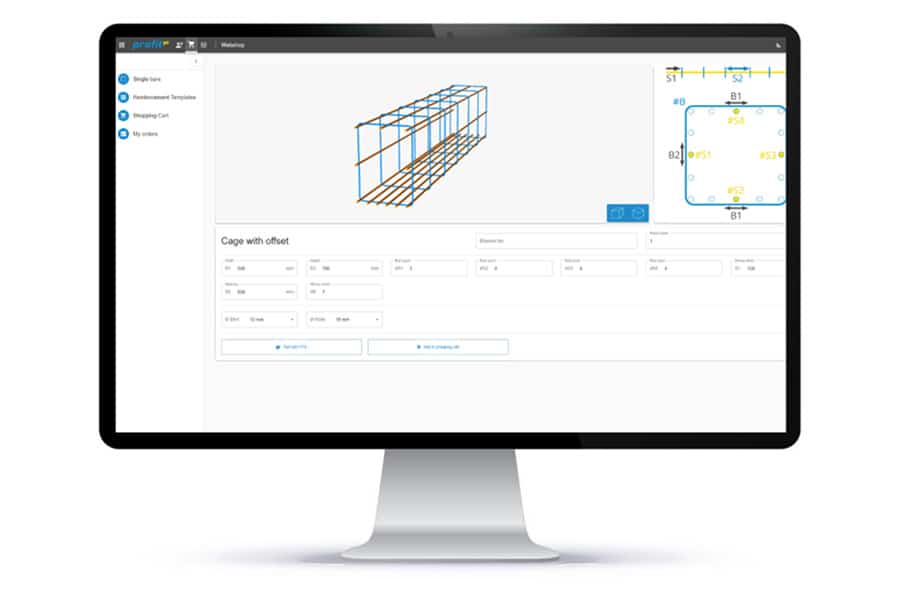

Lammers Concrete's choice of automation is illustrated by the purchase and integration of an M-System net welding plant from Progress Group. The dream of owning such a machine became a reality, leading to significant improvements in production capacity. This installation, coupled with profit software, has streamlined operations by reducing the need for storage and improving production times. The next step taken is to link a bracket machine from an outside vendor to the profit system to further increase productivity and ensure just-in-time production.

What you design is what you get. Therefore, profit integrates a design package to quickly and easily create nets and baskets using predefined models.

Efficiency gains

The investment in both software and automation has provided Lammers Concrete with significant efficiency gains. By producing rebar netting and curved products on demand, the company has optimized storage requirements and minimized waste, while improving the overall quality of its precast elements. Says Moors, "We can produce rebar mesh on time, in the week we need it. This allows us to improve efficiency in the plant and increase product quality."

Positive cooperation

Cooperation with the software and machine suppliers was a positive experience for Lammers Beton. Moors praises the quick response times and expertise of Progress Group's service and software teams, "The quick responses and excellent level of knowledge of the teams were a pleasant surprise. It is crucial to have partners who really know rebar and machine operations."

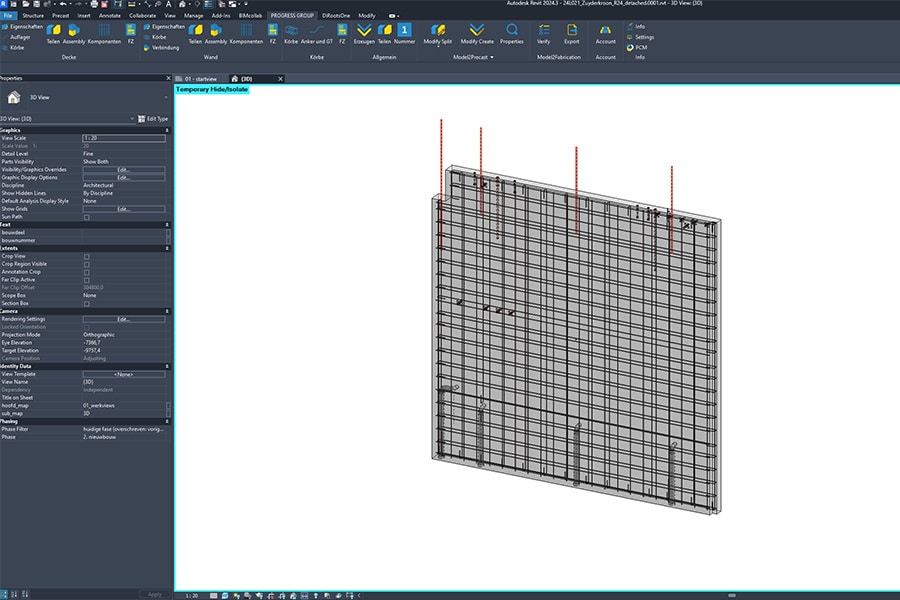

Implementation of BIMpro

In its quest for continuous improvement, Lammers Beton began integrating BIMpro, a software solution designed to further enhance 3D reinforcement modeling capabilities in Autodesk Revit. Initially, the company relied on traditional 2D drawings, which, however, occasionally proved inadequate to represent the full complexity of modern construction requirements. BIMpro provides an intelligent and efficient alternative that allows engineers to design, visualize and plan reinforcement with an accuracy and detail not previously possible. Moors emphasizes the potential of the software: "We are fully convinced that BIMpro will improve the accuracy and efficiency of our designs. It allows us to go beyond basic modeling, because by integrating reinforcement details directly into our Revit designs, conflicts can be better predicted and the manufacturability of the baskets further improved." In addition, BIMpro integrates seamlessly with existing systems and provides quick testing and adjustment capabilities within the program. This integration minimizes the need for time-consuming export and import cycles typical of traditional CAD programs. "Real-time testing within BIMpro in Autodesk Revit means we can address and correct design issues immediately, ultimately improving our production results."

Conclusion

Lammers Beton's strategic investments in software and automation underscore the potential of technology in industrial processes. By using advanced software solutions and industrial automation, Lammers Beton has not only improved its efficiency, but also set the tone for innovation in precast concrete production. Its experiences serve as a compelling example for other companies in the industry considering digital transformation and automation. Thanks to efforts in new technology, Lammers Beton is poised to continue delivering exceptional products and solidify its leadership in the market. Moors sums up the path succinctly, "We didn't just buy a machine; we entered into a partnership to ensure our success. It's about working together to make this happen."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Progress Software Development GmbH.

Contact opnemen

Contact opnemen