Digitization gives complete control of the precast process

Spaansen Bouwsystemen is an innovative family company that supplies complete shells and ready-made facades, including on-site assembly. Nowadays it develops prefabricated facades which are visually and technically indistinguishable from traditional masonry. This is partly possible through digital innovation. Together with partner BIM4Production®, Spaansen has digitized the entire production process. With results.

Once Spaansen Bouwsystemen began as a transport company. Through the concrete industry and hollow-core slab production, the company grew into a precast specialist, with an important role for automation. Although Spaansen has been drawing in 3D for 25 years, until eight years ago the team mainly used these models internally in work preparation. “We saw opportunities to drive the whole process smarter,” says Raimond Lotz, director of operations. “We were looking for automation, better planning control and smarter logistics. That's exactly where BIM4Production® comes in.”

Building smart software together

During the orientation phase, Spaansen compared several software solutions. The choice fell on BIM4Production® because of its flexibility and click with the people behind it. “From day one, Jan Vogelzang and Karel Kamp listened to our needs,” says Lotz. “We immediately noticed: this is not a supplier, but a partner.” The collaboration grew into shared development. “BIM4Production® uses our input to strengthen the platform in its breadth. We benefit directly from this because the platform really connects to our processes.”

Optimal flow

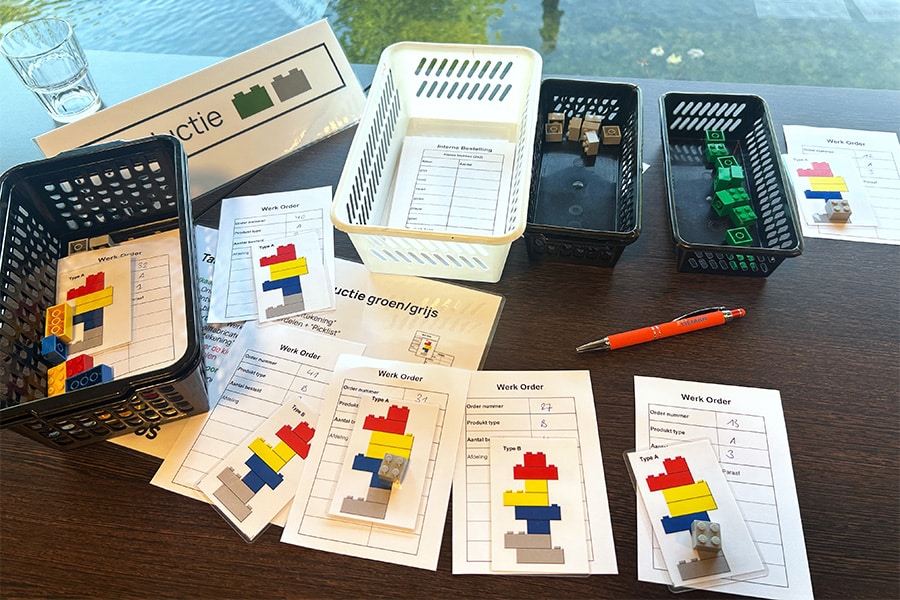

For the new Facade Ready factory, which launched in 2020, BIM4Production® provided the complete data setup within nine months. As a result, the platform is now fully interwoven with Spaansen's production process. From the first square meters at order start to the exact weight in the truck: all data flows along automatically. This way Spaansen minimizes sawing losses and prevents overloading. This ensures an optimal flow. The capacity planning offers insight from global estimate to finely detailed planning. The freight visualization provides real-time insight into tonnages and transport planning. Lotz: “We can now track and control projects down to the last detail. Customers see exactly how their delivery is progressing. Internally, we save time and reduce the margin of error.”

Ready to grow

For Spaansen, the win is in the complete overview. Lotz explains: “We work data-driven. We control the sawing process with minimal waste and avoid overloading. Then we want to know in real time where each element is, both on our own site and on the construction site. That information should soon be available at any time via smartphone or tablet.” Spaansen is ready to continue to grow. Lotz: “We will now also register all quality checks in BIM4Production®. From visual inspections with photos to reject registration. In this way we secure the quality of precast walls completely digitally. All those involved will always have access to relevant quality information, including origin and status.”

One platform, one goal

For Spaansen, working with BIM4Production® feels like co-creation. “What I appreciate most is the involvement of the entire team,” says Lotz. “We think together, challenge each other and always take the next step. We work as colleagues toward the same goal.” And that goal is ambitious. “Our ambition is to further automate processes. BIM4Production® helps us achieve this with flexible support and further development. Together we strengthen each other's business case.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met BIM4Production®.

Contact opnemen

Contact opnemen