Pioneering technology and streamlined processes

Revolution in precast concrete production

In the rapidly evolving landscape of construction technology, Byggelement, a crucial part of Sweden's Peab Group, is setting new standards by integrating advanced software solutions and machine automation from Progress Group. This strategic partnership redefines the precast concrete industry through a seamless combination of breakthrough technology and streamlined processes.

Integration of advanced machinery and software

Progress Group, known for its complete precast technology, has equipped Byggelement with two new carousel plants. At the Hallstahammar location, the plant produces up to three pallets per hour, targeting solid and sandwich walls, made possible by machine automation systems such as the Form Master shuttering robot and eCon Drive concrete pouring machine. Meanwhile, in Ucklum, Byggelement focuses on half slabs up to three meters wide, keeping precision with the help of highly automated processes. Also fully integrated is the M-System net welding plant, which efficiently produces flat netting but also complex baskets from 6 to 16 mm, significantly reducing labor costs and increasing operational efficiency.

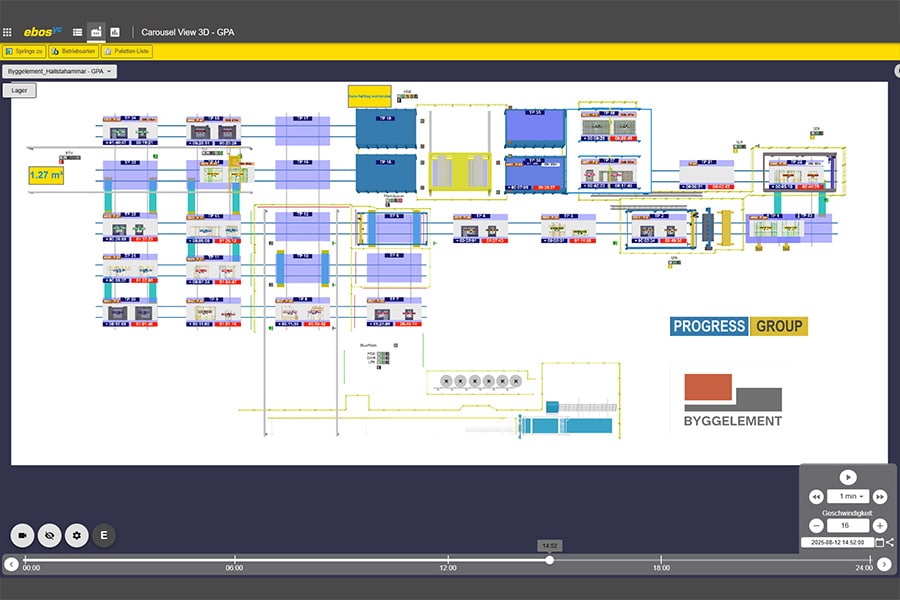

Optimized productivity

A key element of Byggelement's progress is the deployment of software solutions developed by Progress Software Development, a Progress Group company. The ebos software platform provides comprehensive control, monitoring and analysis capabilities. It enables Byggelement to efficiently monitor its entire production process, identify bottlenecks and increase productivity through a detailed digital workflow overview. In addition, the ERPbos system strengthens Byggelement's operations across various functions, from sales and production planning to logistics and billing. Considered the most robust ERP system available, ERPbos supports CSRD by providing insights into the environmental impact of concrete elements, with detailed CO2 calculations and Environmental Product Declarations (EPDs) for various elements and concrete mixes.

Key benefits

Byggelement identified several benefits after implementing ebos:

- Ease of use & learning curve: the ebos platform is user-friendly and quickly enables new users without extensive training. This easy transition is beneficial for those familiar with similar systems.

- Integration & Support: seamless integration of machinery and software ensures efficient operations, and Progress Group's high level of support promotes continuous improvements and strong communication.

- Customization & reporting: ebos enables customizable reporting to meet specific user needs, including crucial metrics such as total weight per element, enabling informed decision-making.

- Stability & reliability: the software offers high stability, with only minor performance delays that are easily manageable.

- Future expansion: Encouraged by the successful implementation of ebos, Byggelement plans to expand the system to more locations and to phase out older systems.

Strategic investment and collaboration in innovation

Byggelement's strategic decision to implement a turnkey plant solution with Progress Group has proven successful both operationally and financially. This collaboration is characterized by excellent service and strong interpersonal relationships, allowing for effective cross-border communication. Byggelement has rolled out these innovations to existing and new facilities, ensuring uniform operational progress. Byggelement emphasizes that strong relationships are crucial to solving unavoidable challenges in unique projects. Progress Group's thoughtful approach is highly valued.

Leading into the future of precast concrete

As part of the Peab Group, Byggelement is among the leading suppliers of precast concrete elements in Sweden, serving construction companies focused on residential projects from 80 to 120 apartments. Through progressive technological investments and robust partnerships such as the one with Progress Group, Byggelement moves to the forefront of the precast concrete industry. It represents a model of seamless integration, advanced technology and visionary leadership, setting new standards for efficiency and innovation in construction.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Progress Software Development GmbH.

Contact opnemen

Contact opnemen