Ultra-smart logistics for dozens of projects simultaneously

With the BIM4Production software, construction companies can control their planning, production and transportation from a single 3D BIM model. The software could just cause the entire construction industry to change.

That is precisely the ambition of BIM4Production. The Rijssen-based company dreams of permanently changing the construction industry. "The construction sector is in need of social innovation," believes Karel Kamp, operational director. "Because the Netherlands has a knowledge economy, foreign workers are mostly used for the real construction activities. This is a development that can be questioned from a humanitarian point of view. Why not enrich our robots, improve production capabilities and let our own knowledge workers do the work? That is what BIM4Production makes possible!"

Ultra-smart logistics

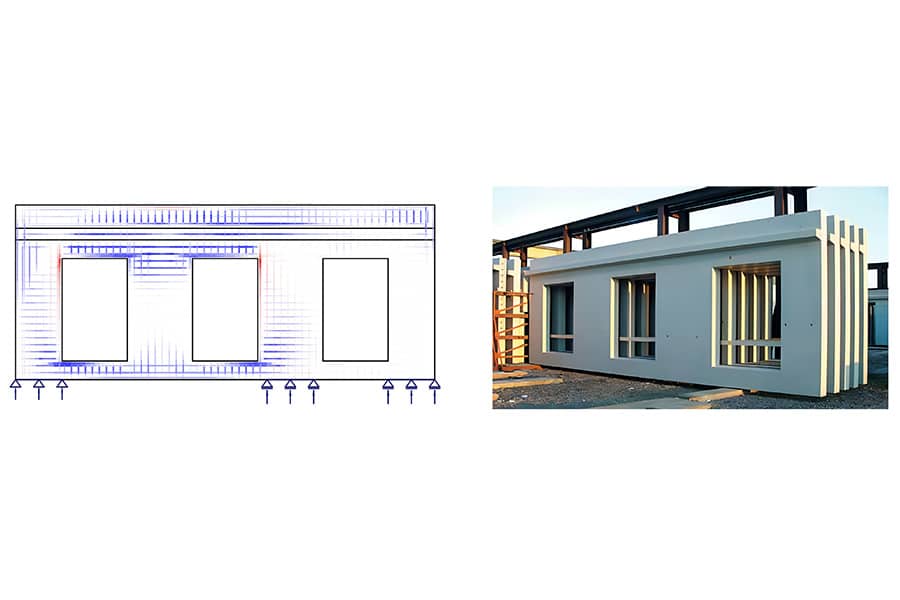

BIM4Production was recently installed at Spaansen, manufacturer of precast concrete wall elements. "Here it is now abundantly clear how construction companies can all function in a few years," Kamp says. "The use of the 3D BIM model is no longer limited to the preparation phase, but has been enriched to the point where it also handles planning and production, transportation, delivery and assembly. The software uses the BIM model of the project as a starting point and then intelligently extracts it into what is needed for planning, ideal sequencing, control of robots, production and transport. In short, it arranges ultra-smart logistics."

The solution to a variety of problems

The software responds not only to social problems in construction, but also to other problems facing the construction industry. Tight construction sites, short lead times and increasingly tight budgets to name a few. In all these situations, BIM4Production provides the smart logistics. At Spaansen, for example, all prefabricated walls and floors are now transported to the right location as efficiently as possible and 'just-in-time'.

Co-creations

The application of BIM4Production is always through co-creation. Kamp: "The best result is achieved if we are involved in the optimization as early as possible; then the client can use our knowledge and experience optimally. Co-creation leads to a clear approach and scope. The long-term dreams, value creations and goals are jointly determined, and then converted into action plans. Through this approach, there is a shared ambition with a long-term vision."

Precisely on a large scale

Thanks to BIM4Production, Spaansen's factory is now highly automated. This allows the company to make an important contribution to the national production goal of 100,000 homes per year. The software effortlessly manages dozens of projects simultaneously, regardless of the number of drawings and the many different elements to be produced. Using the 3D drawing information from BIM, the software creates a visual schedule for all those tens of thousands of elements, right up to assembly.

BIM4Production is generically designed to produce industrial elements. It can therefore handle timber frame elements, prefab bathrooms, window frames, facades, steel structures and other prefab products. Per project, the software regulates and delivers what is needed and when it is needed. The production flow is project-independent. Just-in-time, in other words.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met BIM4Production®.

Contact opnemen

Contact opnemen