Dew point sensor provides clarity during painting, saves time, and delivers predictable quality

Things can take a strange turn, says Anthony van den Hondel of Cathodic Protection Supplies. For decades, he has been involved in protecting concrete structures with cathodic protection. This technique neutralizes the corrosion process using electric current or sacrificial anodes and is a proven method for significantly extending the life of buildings, infrastructure, and steel objects. This involves monitoring to ensure performance over time, through digitization and the application of IoT. Not only does this save a lot of time, it also provides a wealth of interesting and useful data. Could this also be done for painting work, asked a major customer? Absolutely. And so, after a year of testing, the first fifty dew point sensors were delivered in September.

“A lot can go wrong when painting, and one of the most important aspects is insufficient adhesion,” Van den Hondel begins. “This is not due to the professionals, the materials, or the products used, but to the weather conditions during application. If it rains, you can't paint; everyone understands that. But it's less clear when it's just a little too cold. The applicable standard NEN EN ISO 8502-4 stipulates a surface temperature of at least 3°C above the dew point, unless otherwise agreed. If the temperature is too low, condensation forms on the material, whether it is wood, concrete, or metal.”

Errors

To keep a close eye on the conditions under which painting is carried out, you can take measurements manually. But all sorts of things can go wrong. Van den Hondel: “Conditions can change quickly. A measurement taken in the morning may already be out of date an hour later. Or a measuring instrument may be used directly from a heated shed: not good, because the sensor needs time to adapt to the surface. You also see incomplete checks, for example, only measuring air temperature and relative humidity, while surface temperature and dew point are essential. Measuring and recording is manual work, and mistakes can occur. If dew formation goes wrong, you end up with substandard paintwork, which is certainly not what the customer wants.”

Exact dates

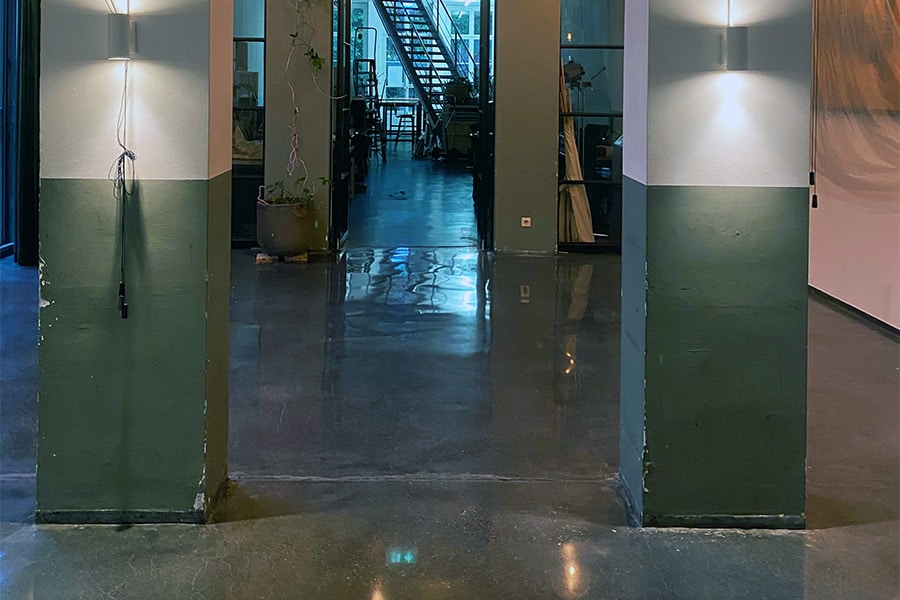

For large customers of painting services, such as housing associations, the Central Government Real Estate Agency, or the Department of Waterways and Public Works, only predictable quality counts. “A client of mine, a large company with which I do a lot of cathodic protection work, likes to deliver that predictable quality to its customers,” Van den Hondel continues. “There, all the measurements taken by the people in the field were entered manually into spreadsheets. That takes a lot of time and the risk of errors is high. My customer then said: can't we do this more intelligently, just like with KB? We immediately started developing a good sensor and, after a year of testing, the first series has just been delivered. They will quickly pay for themselves. Wherever a sensor is installed, work is taken off your hands and no more man-hours need to be spent on manual measurements. The foreman is actively informed and can log in for real-time data. The exact data under which the paintwork was applied is and remains available at all times. This also means that discussions with insurers are a thing of the past. For painting companies, this means quality work based on complete data, knowing exactly when to stop or resume work, so fewer lost hours and no errors in recording. And it's easy to incorporate into the work routine: set up the site hut, place the portable toilet next to it, and then install a dew point sensor.”