Geopolymer concrete performs strongly in Rotterdam port testing ground

Circular and sustainable construction is essential for achieving the climate goals, as these are not achievable with traditional techniques alone. In several living labs, BouwCirculair is working with TNO and SKG-IKOB to investigate sustainable alternatives to linear materials and methods so that they can eventually be applied integrally. For this edition of Concrete & Steel Construction, we take a look at the Geopolymer Concrete Living Lab and, more specifically, at a pilot project of the Port of Rotterdam Authority. The cementless concrete turns out to be an excellent alternative to traditional concrete and even performs better when in contact with seawater.

"If we want to make strides in the field of sustainability and circularity, innovation is inevitable," says Michiel Romer, project leader of Concrete Living Labs at Rijkswaterstaat. "Before new initiatives can really be put into practice, they need to be extensively researched and tested. Preferably this is done in a protective environment, such as a living lab, where they are initially tested at a lower Technology Readiness Level (TRL level). In order to accelerate sustainability, Rijkswaterstaat has set up such living labs for a number of sustainable and circular initiatives, such as the Geopolymer Concrete Living Lab, the Biobased Asphalt Living Lab and the Asphalt Recycling Train Lab."

"To give substance to our climate ambitions set at the national level, so-called 'transition paths' have been set up. Within these transition paths, various breakthrough measures have been formulated that are being investigated and taken further in practice by means of living labs. In the field of concrete, innovative concrete mixtures such as geopolymer concrete are being tested, but also think about alternative concrete reinforcement or about stimulating the concrete recycling chain."

Interaction with the market

The living labs are indirectly the result of the Climate Neutral and Circular Infrastructure (CIP) strategy as drawn up by the State. "It also ties in with the Concrete Agreement, which stipulates that the proposed measures must actually be implemented. That makes for a nice interaction with the market," according to Romer. "The living labs therefore involve all kinds of market parties, from large to small. So a living lab has multiple locations. Ten projects have been registered for the application of geopolymer concrete, including one in the Port of Rotterdam. Four projects are being monitored by TNO. Six projects follow a different monitoring plan, the Port Authority project being one of them. By sharing data and results among the ten projects, the sector can develop together. In the living lab, experience is gained with processing, behavior immediately after dumping the material and ultimately long-term behavior through long-term monitoring of the structure. The ultimate goal is to obtain really good, independent information about the long-term behavior and thus stimulate the use of sustainable geopolymer concrete in the market and among clients. It will also allow data to be collected for further regulation of geopolymer concrete."

Biggest contender

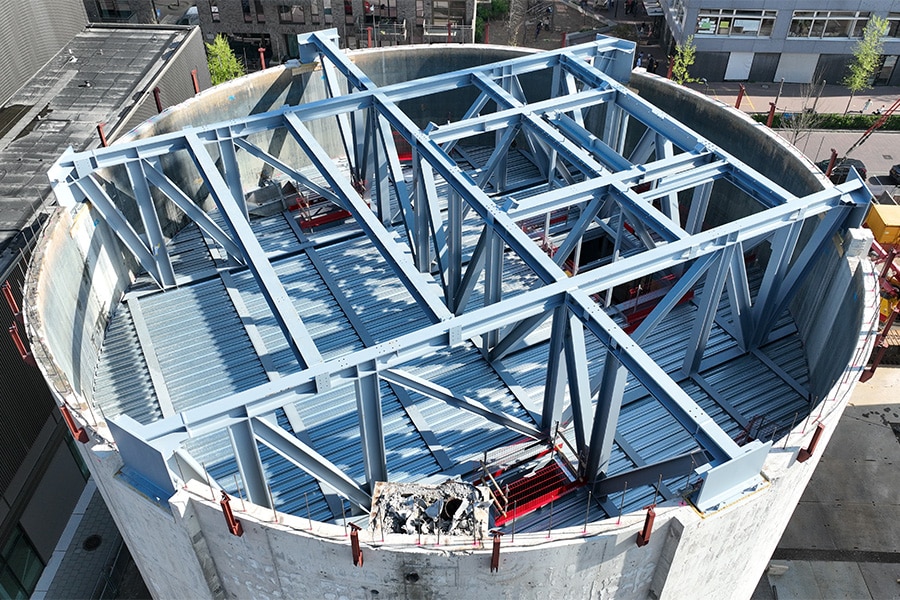

Port of Rotterdam Authority wants to be a leader in safety and sustainability. "About three years ago we translated our vision of sustainability into practical projects," says Patrice Nederhorst, Port Engineer at the Port of Rotterdam Authority. "In the end, it turned out that in terms of material use, we can make the biggest difference with concrete and steel. Within the concrete sector, we identified geopolymer concrete as the biggest contender. So three years ago we started research to determine what performance the mixture would have to provide for application in our port. Based on this, a test program was set up and we asked market parties to develop a suitable recipe. SQAPE was the only one that could meet the requirements. First the mixture was tested on a laboratory scale, then in a pilot landfill in larger volumes of 10-15 m3. Then, in May 2024, we completed the first quay wall with geopolymer concrete, with a total volume of about 500 m3."

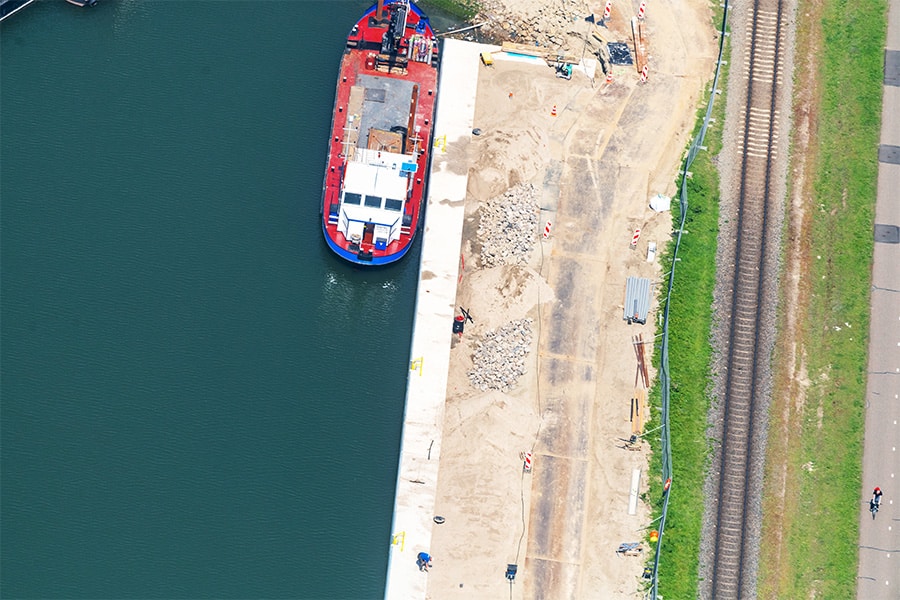

High penetration resistance

The first major project in the Port of Rotterdam using geopolymer concrete has been so successful, according to Nederhorst, that the sustainable concrete is a serious alternative for subsequent projects. "Per project we look at which mixture fits best, but we see many advantages in using geopolymer concrete. We save about 40 to 45 percent in CO2 emissions. Beyond that, it also performs very well in contact with seawater. It has a higher penetration resistance to chlorides than traditional concrete, we infer from our monitoring data. With data from the next few years, we can quantify how much life extension it can provide. We expect the service life of geopolymer concrete to exceed that of traditional concrete."

One step further

The Port Authority is already planning the next major project using geopolymer concrete. "That it performs well is clear by now. Now we need to investigate whether we can scale up production and application to larger volumes," says Nederhorst. "The next project in which our ambition is to process 15,000 m3 of geopolymer concrete is now in preparation. The big difference with the previous quay wall is that now we also want to include bollards and all kinds of mooring facilities in the concrete. Just another step further, but still not a fully constructive application. Although we are slowly moving in that direction. We have a lot of confidence in this type of concrete."

Scaling up

Currently, geopolymer concrete is being applied within RWS in controlled experimental spaces. This meets the need for additional substantiation of the potential. The living lab with the Port of Rotterdam Authority is now entering the phase to map the actual potential in terms of, for example, lifespan, circularity and structural safety. More information about the Geopolymer Concrete Living Lab can be found on the BouwCirculair site.