Pluggable installation embraced by installer and contractor

Attema introduced its ‘100% Install 2.0’ concept 2.5 years ago: an installation solution that enables fully pluggable installation in residential construction. In doing so, Attema makes use of the installation space in hollow walls and suspended ceilings. It thus offers the possibility of faster, safer and cheaper construction. Last year we spoke to Attema about its new floor and wall boxes with which it also offers a fast installation method for (prefab) concrete walls and floors. Curious about its growing impact on the construction industry, we spoke to project manager Richard van de Wiel and his colleague and technical advisor Lowie van Schijndel.

“Since the introduction of Install 2.0, interest from the market has skyrocketed. The enthusiasm was already great, but is only increasing due to current developments,” Van de Wiel tells us. “Indeed, more and more installers and their contractors are discovering the benefits. They realize that with time savings you can ultimately achieve the biggest savings on a project. Lately we've noticed that installers are actively taking the solution to their contractors. That creates a nice chain reaction.” Van Schijndel adds: “Prefab construction is increasing rapidly and in combination with our system you can reduce failure costs and save considerable time. In fact, the installation time decreases by sixty percent with our concept. The higher material costs are then more than compensated by the lower TCO. If required, we think along with the customer from the very first phase of the design stage, which can also be the contractor's client. In doing so, we not only make the construction process more efficient, but also take away worries from our partners.”

Distinctive concept

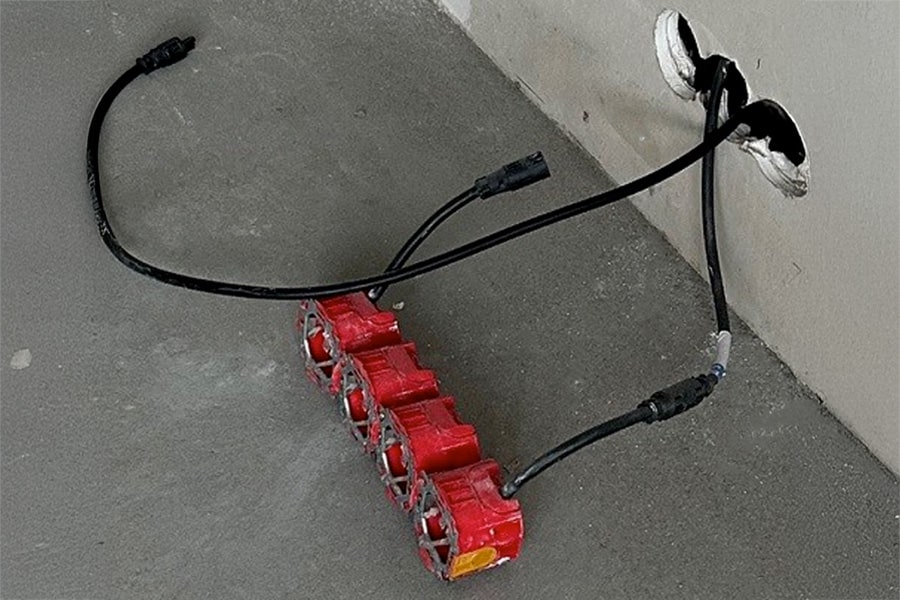

One of the things that really excites users and sets Attema apart is the round plug. Van Schijndel: “We deliberately chose this principle because making square cutouts is expensive. Our plugs fit through a 25-millimeter drill hole, which is easy to drill or mill.” In addition, Attema deliberately chose to work with color coding. “On the outside of our pre-wired surface-mounted and center boxes, the colors of the cables correspond to those in our drawing. The lengths are also shown on the cables. This makes it immediately clear to installers, precast builders and concrete workers where each cable should go. We often work with filled kits, made by the wholesaler, containing all the products for a particular space. If the box is empty, then everyone knows that the electrics for that space have been completed.”

Expanding product range

Since we spoke to Attema last year, it has also expanded its product range for Install 2.0. “For example, a coupling sleeve has been added for wood and steel frame builders. In it, at the head of the wall, the cables are pre-fixed and capped so that nothing sticks out of the wall and a quick and watertight connection can be made on site. The fact that there are no loose cables sticking out of the elements also gives a huge advantage during transport, of course, because it prevents damage,” said Van de Wiel. “By the way, this is one of the products we are taking to the PREFAB fair in the Brabanthallen in early October.”

Future

Pluggable installation is more topical than ever, Van Schijndel explains to us: “Not only because prefab construction is growing tremendously, but also because the delivery schedule still sometimes changes. Then it is quite a challenge for the contractor to get everything done on time, and our system offers a pleasant flow to a project.”

Favorable MPG score

Van de Wiel: “Pluggable installation will increasingly become the norm, especially given the increasing focus on circularity, CO2 reduction and thus the MPG score. Our systems are reusable and recyclable.” Whereas initially the system was mainly used in residential construction, the gentlemen now also see growing use in non-residential construction, such as office buildings and healthcare complexes. “We have lengths up to and including fifteen meters, and especially in repetitive construction, think of care units or shelter locations, then our system works ideally.”

Attema regularly works with developers such as Rebuildit Group in Nieuw Amsterdam. Transformation projects are also the order of the day, such as at former Valkenburg Airport, where 44 homes for status holders are currently being realized. “By preparing everything plug-and-play in advance, you can finish such a project extremely quickly and efficiently,” Van Schijndel concludes.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Attema B.V..

Contact opnemen

Contact opnemen