Precise measurement data can prevent costly concrete repairs

Monitoring concrete and rebar

BAG-MacBen has specialized in the sale, service and calibration of measuring and testing equipment for the construction and concrete industries since 1992 and has since become a leading knowledge company in the sector. It distributes only high-quality equipment and its calibrations are ISO 17025 certified. The carefully compiled range of high-tech test equipment is also largely available through its own webshop.

Three aligned segments

BAG-MacBen targets a triple clientele of construction companies, contractors and geotechnical/construction research centers or educational institutions. Fully in line with its slogan "Concrete Quality Solutions," it has the stated ambition to play a leading role in the world of test equipment for the construction industry. Sales Manager Tom Ryckeboer: "We are making this ambition a reality with a team of highly trained and motivated employees, a high degree of product knowledge, technical support throughout the entire process, officially recognized and standardized calibration services and various training courses, both in situ and in our own lab."

Careful monitoring of concrete and rebar

"We have products in our range that are specifically aimed at building with concrete," said Ryckeboer. "They are all smart solutions that ensure that the cost of concrete repairs is kept to a minimum, that concrete structures have a longer life and that the safety of users is never compromised. After all, concrete and rebar are subject to external influences, and when these are not adequately controlled and monitored, the stability of a structure can be compromised."

Corrosion and moisture damage to concrete

One monitoring that is well worth its price is the Corrodec, a dedicated corrosion and humidity sensor. It detects early corrosion activities that largely determine the remaining life expectancy and potential maintenance and repair costs. Corrodec sensors are wireless, powerless, remotely accessible, expandable, easy to use and extremely precise in terms of evaluation.

Cracks and static changes in concrete

Cracks and static changes in a concrete structure can be caused by underground mining, groundwater subsidence and proximity to open or underground construction sites. A specialized sensor from BAG-MacBen makes it easy to measure and monitor these cracks and deformations. The sensor measures cracks inside and outside the structure at critical locations and sends an alert when preset limits are exceeded. The sensor transmits wirelessly and remotely all measurement values and has an internal memory with logging. For very specific construction projects, these sensors can be custom designed and manufactured according to specific needs.

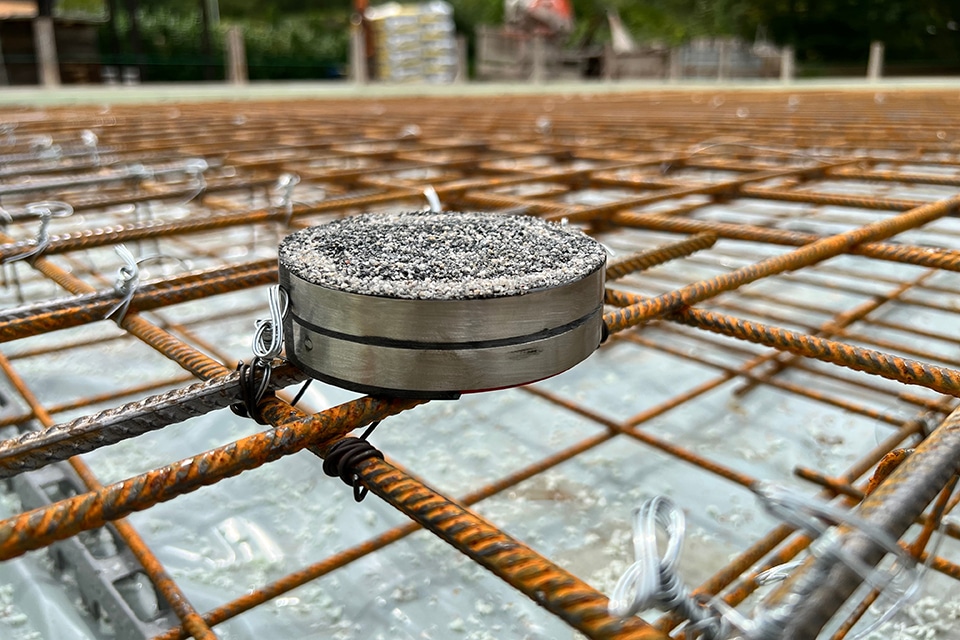

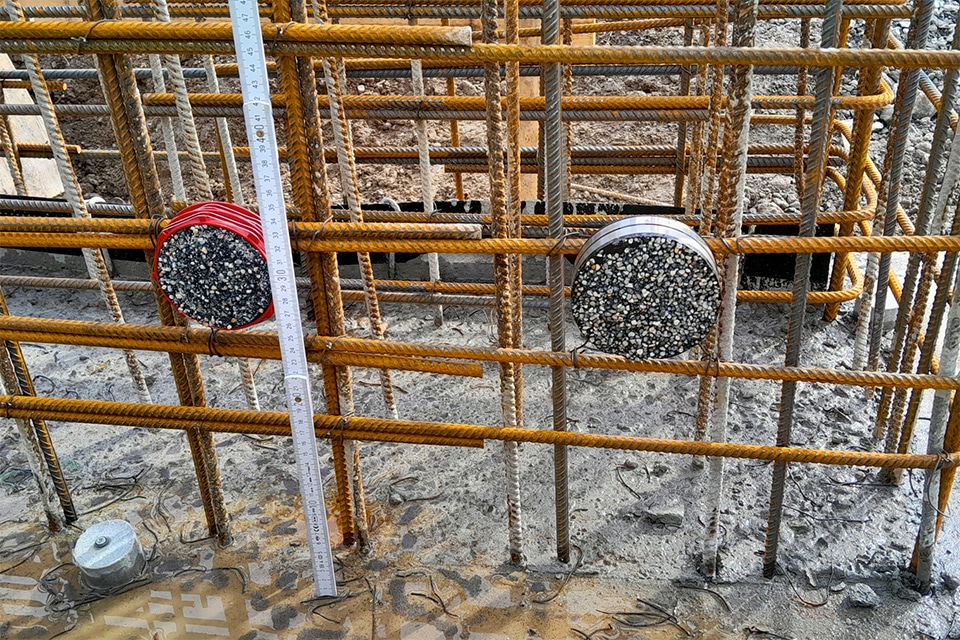

Temperature and strength monitoring of concrete

A third dedicated sensor is the "Smartrock," which monitors temperature and strength of the young concrete. The sensor is fully embedded in the concrete, making it protected from damage and harsh construction conditions after pouring. Installing and labeling the sensors takes only minutes. It is a wireless and powerless sensor that can be controlled remotely via the 'SmartHub' application and with a signal range of up to 12 meters. The sensor operates on an ASTM and ACI approved maturity method and provides 24/7 insight into the status of a deposit. The measurement is already more accurate than this with cylinder breaks in the field and provides an accurate and reliable in situ test to measure young concrete strength. This method of monitoring also avoids the intervention of external testing laboratories.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met BAG-MacBen bv.

Contact opnemen

Contact opnemen