Prefab shell specialist takes care of everything for contractors in prefab construction

Contractors who are hesitant about prefab construction often balk at higher costs and a lack of flexibility during the design and construction phase. “Unjustified and unnecessary,” Silvester Snijders reassures them. “As long as you work with a party that knows what it's doing, prefab construction offers many advantages. For example, the construction time is considerably shorter, the quality of the concrete is much higher, and the failure costs are significantly lower.” As co-director of Stabiel Management, he has extensive experience in the realization of smart constructions and prefab shells for residential towers, schools, hotels, offices, and care centers.

As a prefab shell specialist, Stabiel Management occupies a unique position. Whereas many parties only provide advice, it is one of the few that also takes on the entire prefab shell for a fixed price. This is because it has all the necessary construction knowledge in-house. “We provide advice early on in the design phase and design the prefab construction in such a way that it can be realized smartly and at minimal cost. We then take complete responsibility for project management, work preparation, development, engineering, production, and assembly. This means that the contractor is completely relieved of any worries, and the risks and any failure costs are borne by us. The savings in construction site costs and preparation are for the contractor.”

Integrated development

Good planning is crucial in prefab construction. “For example, the installer will have to provide the necessary pouring facilities earlier than in traditional construction,” says Snijders. “Knowledge is really an important ingredient in successful prefab construction. If sufficient prefab construction knowledge is available during the advisory phase, you can immediately see the impact of certain design choices on costs and planning. Prefab construction is different from on-site pouring, and you need to be aware of the structural limitations and possibilities. We often see that consultants have too little knowledge, which means that the manufacturers who are involved at a later stage and do have the knowledge no longer have any influence on the design. These are missed opportunities.”

Consultant and manufacturing partner

The combination of thorough construction knowledge of prefab building and experience in implementation is ideal for contractors who want to build prefab but do not have much knowledge of it themselves. But also for projects that are too large and/or too complex for a contractor. “We bridge the gap between advisory parties and manufacturing parties by doing both.”

Impressive portfolio

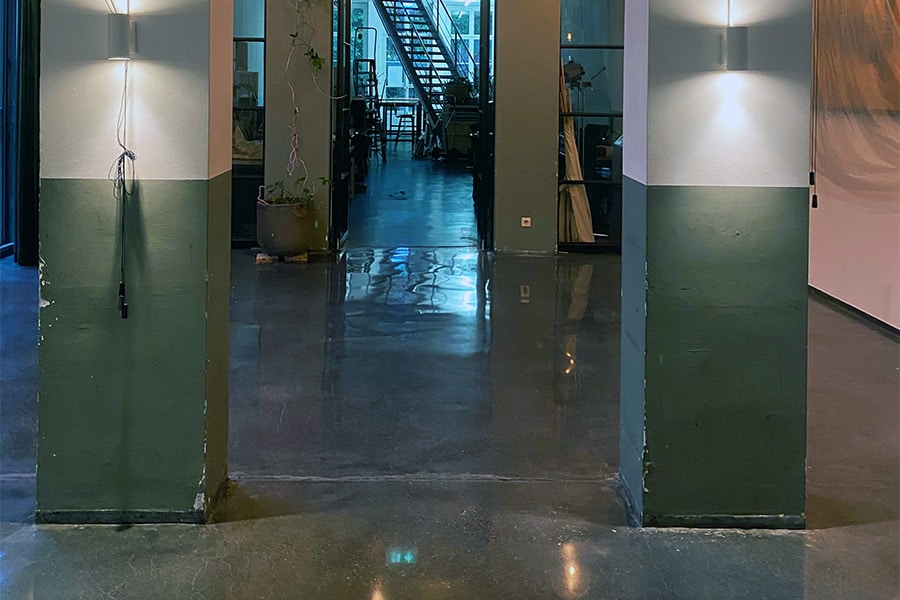

This formula for success is reflected in an impressive portfolio. Stabiel Management recently provided Jongekrijg Maasbouw with the complete prefab shell (including engineering, delivery, and assembly) for the new Culture, Education, and Media Building in Ridderkerk. The shell consists of prefab concrete walls with a wood motif, steel columns, steel beams, wooden columns, and wooden beams. A beautiful mix of materials and disciplines, making it a stunning hybrid shell. Snijders: “As a permanent partner of VORM2050, we were also responsible for the engineering, project management, and realization of the prefab shell of High Five in Utrecht. This involved the construction of two residential towers, each with 21 floors, and is a fine example of the speed with which we can work. We only needed four days per floor, including the installation of the prefab bathrooms and all finishing packages.”

He concludes by inviting contractors to have their designs checked: “We are happy to do so, and within a day we can already indicate whether the design is suitable for prefabrication!”