School building as 'construction kit' from Apeldoorn concrete factory

In the heart of Bloemhof, a new neighborhood in Rotterdam, not only homes are being built, but a completely new school building is also rising in no time. The latter is thanks to the fully prefabricated concrete shell. Commissioned by Middelwateringbouw, Preco was responsible for the engineering, production and delivery of the concrete floors and inner walls, which were delivered to the construction site as ready-to-use kits.

Preco profiles itself as a total supplier of high-quality precast concrete structures. "We are an established partner for many parties in non-residential construction and annually supply many square meters of walls and floors for large distribution centers," says Robbert Blokland, project manager at Preco. "Because of the high speed of construction, we also get more and more requests for more complex shells, in which we directly incorporate part of the installations. That requires just a little more coordination and attention in the preparation. And so that was also true for the concrete shell of the new school building on 2e Balsemienstraat in Rotterdam."

Three building layers

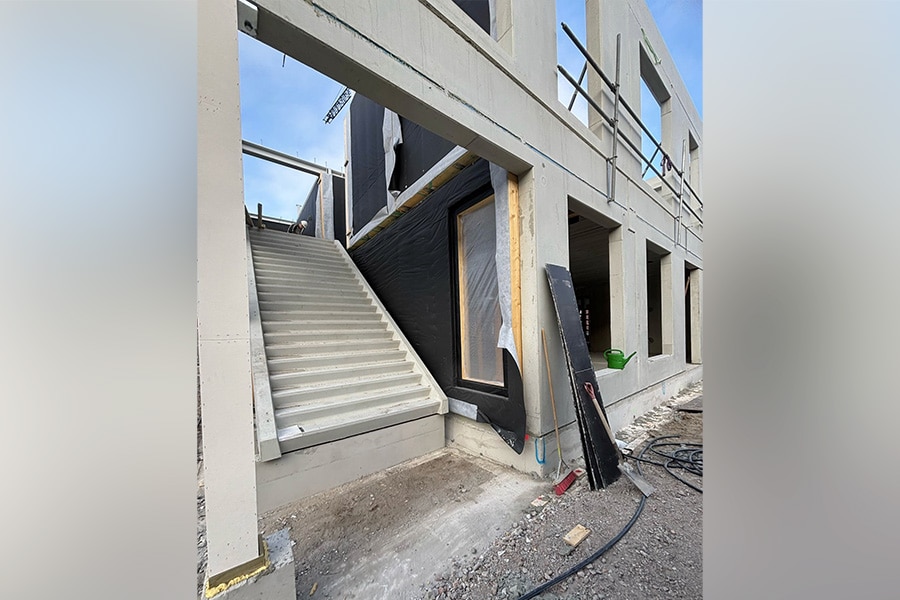

The new school building consists of three equal storeys and has two floors to match the street structure of the neighborhood. "From Preco, we supplied the floors on behalf of the ground, first and second floors, plus the roof. They are all hollow-core slabs made to measure. We also produced and delivered all the structural walls, as well as the stairs and lowered roof floor for the benefit of the technical installations. So the complete concrete shell," Blokland summarizes. But before it came to that, Preco first provided the engineering for each floor. "We started by setting up the main form and then built it up in detail, step by step, for each storey. It requires a completely different approach than, say, the elaboration of a distribution center." He refers mainly to coordination with the various parties.

Ready-made

In the precast walls and floors, Preco provided the necessary cutouts for the toilet groups and all the piping, among other things. "We even incorporated the electrical boxes into the walls at the factory. That sometimes meant that we were working with different models to fine-tune everything in detail. And then we also had to deal with a pretty tight schedule. The lead time for these walls in production is also slightly longer than that of regular insulation walls for a distribution center. That is mainly repetition work; these walls are slightly more laborious. Apart from all the pouring provisions, we also had to install an extra ridge on the pouring side. So we were able to produce two walls per day. That amounts to a week and a half per level. Each storey has twelve walls."

The walls and hollow core slabs were transported to the construction site in Rotterdam from Preco's factory on a layer-by-layer basis. "Assembly partner Bincx then assembled the shell in just five weeks. Due to the good preparation, it was only a matter of stacking and the nuisance on the surroundings was limited. An additional advantage of building with precast concrete." While the precast concrete shell was up in no time, the finishing work takes a bit more time. The new school building is expected to be completed by the end of 2025.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Preco.

Contact opnemen

Contact opnemen