Smarter design with sustainable concrete offers opportunities for engineers

Concrete is one of the largest contributors to CO2 emissions in construction worldwide. Much of that is caused by the use of Portland cement, which has high CO2 emissions during production. Fortunately, alternatives are available. Engineers can make significant gains as early as the design phase by consciously choosing more sustainable concrete mixes. Consider concrete with ground granulated blast furnace slag, which significantly reduces CO2 emissions without sacrificing quality.

The greatest opportunities for sustainability lie in the initial design phase. This is where choices are made about volumes, construction methods and materialization. If concrete with lower CO2 emissions is targeted even then, design and planning can be adjusted accordingly. It is therefore important that engineers sit down at the table with concrete suppliers, contractors and their sustainability specialists at this stage.

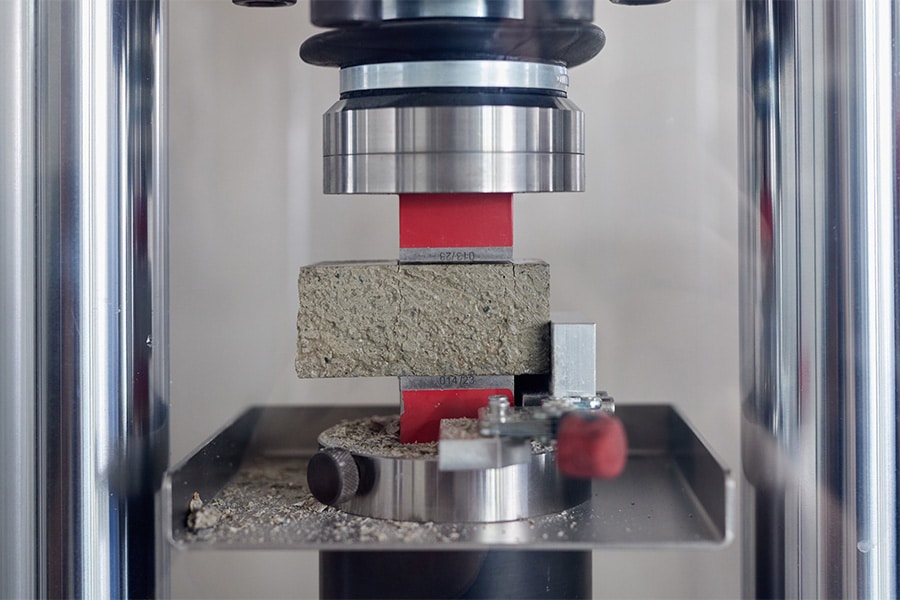

Sustainable concrete works differently

Concrete with a lot of blast furnace slag initially develops strength more slowly than concrete with Portland cement, CEM I, with more than 95% clinker. This slower strength development requires a different process. Engineers must take into account, without measures, longer curing times and possibly a modified construction phasing. In practice, this means waiting a little longer to uncast and/or working with alternative schedules. This requires some adjustments at first, but it definitely pays off because the CO2 savings that can be achieved are large. Adding heat to concrete with ground granulated blast furnace slag helps to increase initial strength when the schedule calls for it. Concrete based on blast furnace slag is not only more durable, it also develops less heat and requires less maintenance over time. It is denser and more resistant to chlorides and chemicals, making it ideal for infrastructure, hydraulic engineering or mass concrete.

MKI as a steering tool

The Environmental Cost Indicator (EQI) makes the environmental impact of materials visible in euros. In more and more government projects, the MKI is therefore being used as an award criterion. By asking for a maximum MKI value in the tender, the market is forced to come up with more sustainable solutions. Engineers can thus compare different concrete options side by side. A mix with 100% CEM I quickly comes out to an MKI value of €26 per m3, while for a mix with more than 50% ground blast furnace slag, this is only €13. That is a halving of the MKI. Because 50 to 60% of concrete's MKI is determined by CO2 emissions, clinker replacement has an immediate impact. These are figures that engineers can use to convince clients. Because sustainable concrete is not necessarily more expensive. In fact, in many cases it is cost-neutral, especially if you look at the entire life of the building. So engineers who include the MKI in their design calculations are really making a difference. Consulting early on about performance, requirements and construction phasing creates feasible solutions that are also sustainable.

Collaboration with knowledge partners pays off

Engineers don't have to come up with it all by themselves. Suppliers like Ecocem Benelux actively think along in the VO and DO phase. They offer technical support, share experience from other projects and can help to calculate different concrete mixtures. This ensures early identification of risks and the ability to resolve them. There are times when an engineer or contractor has doubts about slower strength development at lower temperatures. In that case, the concrete mix can be adjusted or heat can be added .

Are there doubts about allowing sustainable binder systems within the regulations? Then additional test data can be provided or consulted with the supervisor. Sustainable binder combinations with ground granulated blast furnace slag are simply permissible within the regulations through technical approvals and certification. Thus, new concrete mixtures are more likely to be accepted and applied.

Give space to innovation

Contracts or specifications specify an environmental class and a minimum strength at 28 days. In particular, the requirement at 28 days could limit innovation because a durable binder will not reach this strength (yet). A durable mixture then drops out, while it perfectly complies after 56 days, for example. This is why performance-based specification is gaining ground. Here you give the client or engineer the opportunity to specify the strength at 56 or even 91 days. Within the standards, of course. This creates room for innovative mixtures with ground blast furnace slag, fly ash or geopolymers. NEN-EN 206 already offers this flexibility: strength may also be demonstrated after 56 or 91 days. By deliberately applying this, engineers can design more sustainable without making concessions on quality.

Building the future together

The construction industry needs and wants to become more sustainable. Concrete with lower CO2 emissions plays an important role in this. Engineers can make the difference in the early design phase, by consciously choosing sustainable mixtures, including the MKI in their considerations and thinking performance-oriented. Together with suppliers and clients. With tools, data and practical examples, sustainable design becomes an opportunity rather than a risk. For the environment, for the sector and for the image of everyone who works on it. Because those who design smartly now, help build a cleaner future.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Ecocem.

Contact opnemen

Contact opnemen