Never so economical: wall formwork system Manto G3

New generation with numerous advancements

Under the name Manto G3, Hünnebeck introduces a new generation of the MANTO formwork system for large wall surfaces. The Manto G3 system has a maximum concrete pressure of 80 kN/m2 and can be widely used in civil engineering and construction. Its high functionality and durability are remarkable. Numerous further developments make formwork even faster and more flexible. At the same time, compatibility with the Manto G2 generation remains guaranteed.

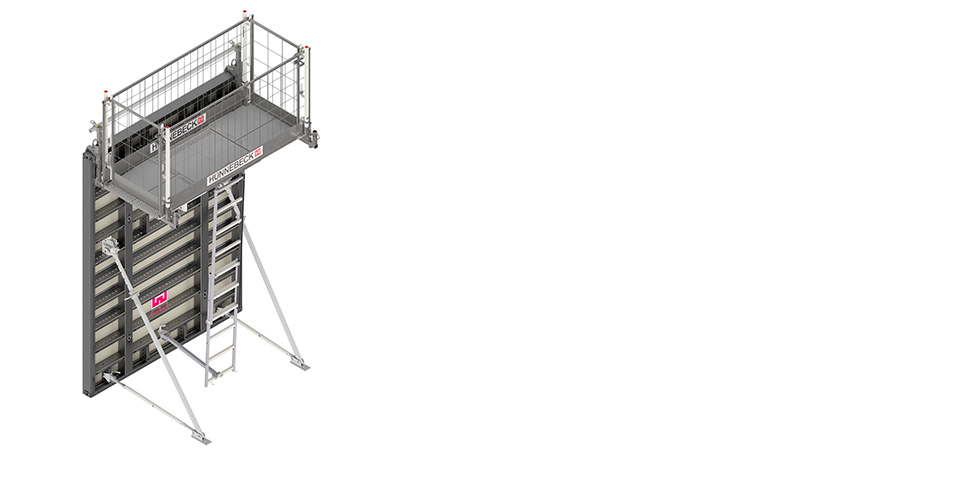

Universal working platform for the MANTO wall formwork system

Saving time and costs with single-sided anchoring

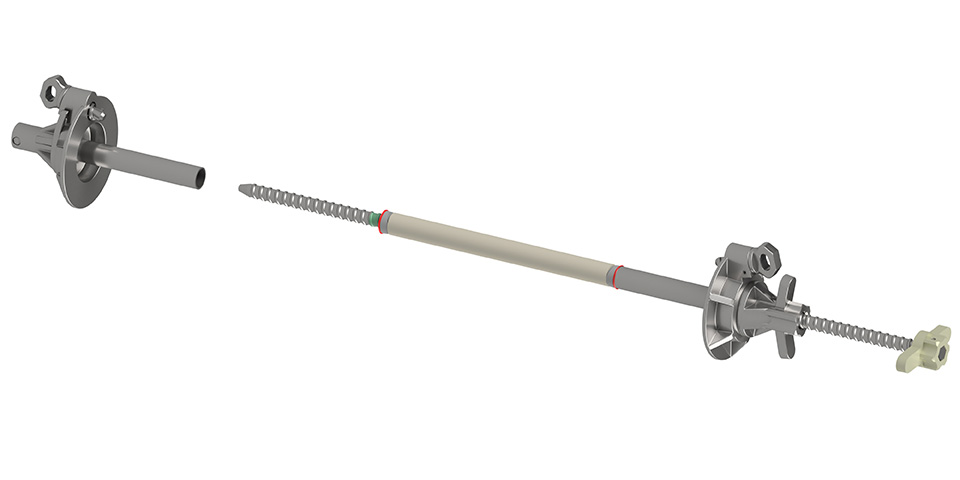

For fast progress on the construction site, the new, single-sided operable anchoring technology of the Manto G3 formwork is particularly important. This technique is possible thanks to the Platinum 100 anchoring system and the special Manto DW 15 anchor. Alternatively, conventional DW 15 and DW 20 anchors as well as She-Bolt anchors and Taper Ties can be used.

In single-sided anchoring with the Platinum 100 anchor, the wall thickness can be infinitely adjusted; marks spaced 2.5 cm apart facilitate the process. Compared to the previous generation, the Manto G3 features larger anchor openings; these allow for an anchor clearance of up to 2.5° and thus facilitate the work. Interchangeable plastic inserts protect the anchor openings from contamination and concrete and allow quick adaptation to different anchor systems.

MR anchor system

New panels: more stable and easier to assemble

The panels of Manto G3 were also modernized and further strengthened. For example, vertical ribs increase stability and provide all-round connection options for transport hooks.

The center vertical ribs additionally serve as quick connections for directional braces as well as for standard formwork alignment and protection from below. Optionally, integrated clamps are available. These ensure even greater efficiency because clamps can no longer be lost this way.

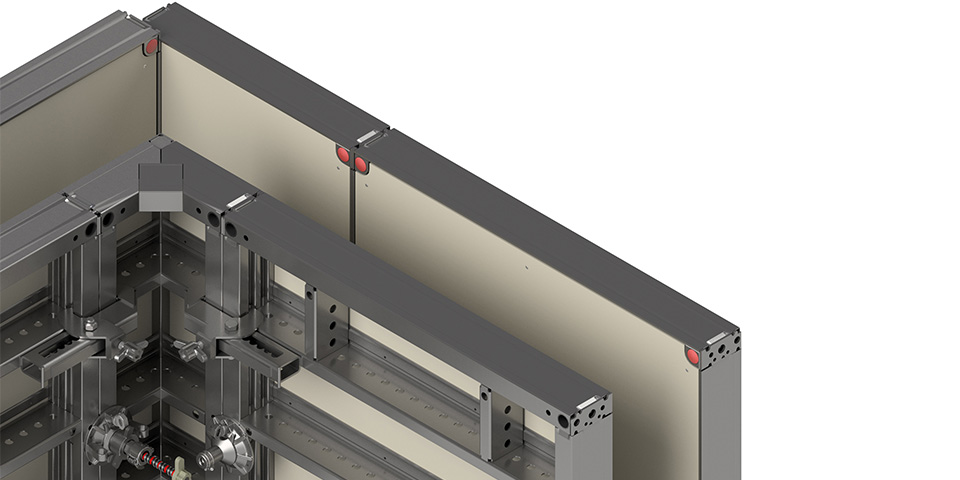

Another new feature is the rigid Manto G3 inner corner for added stability. The transverse ribs have the same profiles as the panels and allow for a seamless connection. Because the open profiles have been dropped, there is less chance of contamination and cleaning costs remain low.

MANTO angle with PLATINUM pin

Plastic formwork plate for high-quality and even concrete appearance

The new 19 mm thick plastic formwork plate also reduces cleaning costs. That plate guarantees a high-quality and even concrete appearance and reduces the need for rework of the concrete. Its long service life (approx. 3 times longer than traditional wooden variants) is further enhanced by the steel-coated anchor openings. This prevents damage to the formwork skin by the anchor rods.

In the special system variant Manto G3 M, the panels-different from the G3 generation-have interior anchorages. These ensure a symmetrical anchoring pattern. The comprehensive range of accessories for the Manto G3 system can of course also be used with these panels.