Steel frames: an innovative solution for more efficient construction

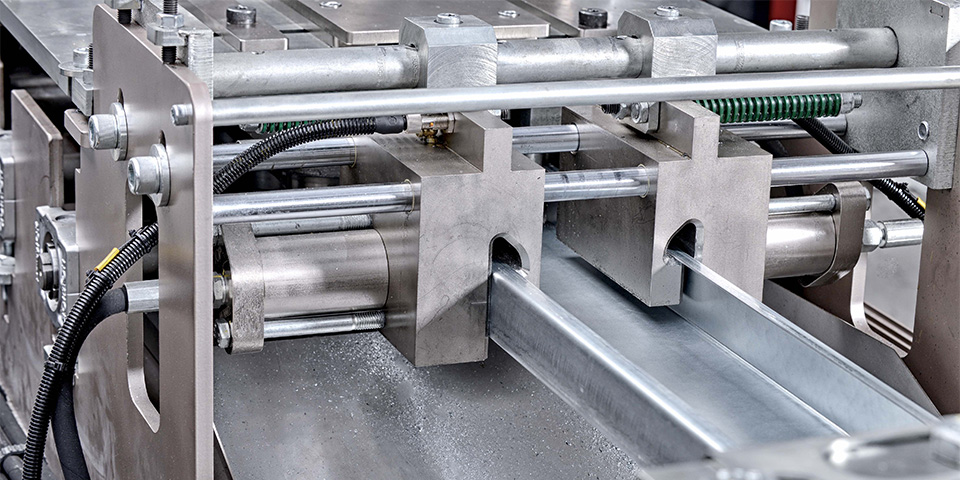

Steel and steel frame profiles are produced in our own factory

The use of steel frames allows contractors to work more efficiently on construction sites in an innovative and sustainable way. They can be used for a variety of applications. From house and apartment construction to facade construction and industrial construction and in both new construction and renovation projects. Finish Frame, part of the Finish Profiles Group, produces cold-rolled steel frame profiles for applications in housing construction, hall construction and partial construction. The Purmerend-based company supplies complete load-bearing structures as well as substructures, such as exterior cavity walls, load-bearing partitions and roof trusses.

Finish Frame's steel frame system consists of cold-rolled C sections. They are drawn with a 3D drawing program and then converted to production. The C-profiles are rolled from a steel coil (S320) with a galvanized layer of galvanized steel or aluzinc of 275 gr per m². As a result, the profile is well protected against various environmental and weather influences and can last more than 60 years with a dense construction. The profiles are ideal, for example, for roof trusses, interior walls and fair construction, load-bearing walls, exterior cavity walls, purlins, floors, portal frames and prefabricated roof modules.

The steel profiles are rolled in thicknesses from 1.2 mm to 2.5 mm and are available in 6 widths: C75, C100, C150, C200, C250 and C300. This allows walls or floors to be load-bearing, as part of a building or as a complete structure.

"We carry out the necessary processing on each C-profile to ensure that the profile becomes a usable element. For example, screw holes, through-holes and bolt connections are possible to make this frame 'custom-made,'" Dennis Eikenboom states. "The steel profiles are rolled in thicknesses from 1.2 mm to 2.5 mm and are available in 6 widths: C75, C100, C150, C200, C250 and C300. This allows walls or floors to be load-bearing, as part of a building or as a complete structure."

Many advantages in construction projects

By processing the C-profiles in various ways, prefabricated elements are created. Thanks to the properties of the profiles, these elements can be built much lighter, more creative and cheaper. "By building with load-bearing elements for facade, floor and roof, the construction time is significantly reduced. The recesses for windows and doors as well as all connection points are already integrated into the elements. The frame is also the main supporting structure, eliminating column structures. Thanks to these prefabricated elements, a house can be finished in one week," Eikenboom adds. "The steel frame profiles are also very durable and strong. Thanks to the galvanized layer of zinc, the structural steel remains fully protected, so it lasts forever. Moreover, the steel can be fully recycled again. The open structure makes it easy to integrate insulation and also creates less waste during disposal. A steel frame can also take more pressure than a timber frame wall, for example, and the connections can be made stronger, allowing elements of greater heights to be better suspended from the main supporting structure."

Finish Frame performs the necessary processing on each C-profile to ensure that the profile becomes a usable element. For example, screw holes, through-holes and bolt connections are possible to make this frame "custom-made.

Building more efficiently

Finish Frame steel frames lend themselves extremely well to modular construction. The module can be entirely self-supporting in steel frames without the addition of hot-rolled profiles. "These profiles make it possible to build more efficiently in an innovative and sustainable way," concludes Dennis Eikenboom. "Our customers can also count on the necessary technical support. We take on the complete engineering and production. We can produce the desired element from the customer's drawing software, but we also have our own drawing and calculation department with experience in working with these steel frame profiles. They can draw out the frames and then communicate this to the customer via BIM or otherwise. The customer can control our machines directly, so the profiles can be produced very quickly."