Strong in production, maintenance and emergency response

For many years, Aquavia has specialized in the maintenance and emergency monitoring of several important waterways and engineering structures in our country. But its services go much further. Whether it involves concrete, steel or other materials, the specialist does not shy away from it. Thanks also to the professionally equipped (steel) workshop and the company's own working vessel Ingrid B.

From the 'island' of Sas van Gent, Aquavia, part of VolkerWessels' KWS Infra Roosendaal-Sas van Gent, works on a wide variety of projects. "We are a very broadly oriented company that operates with different disciplines mainly in hydraulic engineering and industry," says project manager Manno Buijsrogge. "Our employees are all-round deployable. That also makes us so flexible. Our work ranges from minor concrete work and maintenance, repair or construction of new quay structures to the realization of steel structures of all types, shapes and sizes. Should the need arise, we can always call on our internal (parent) organization to strengthen ourselves."

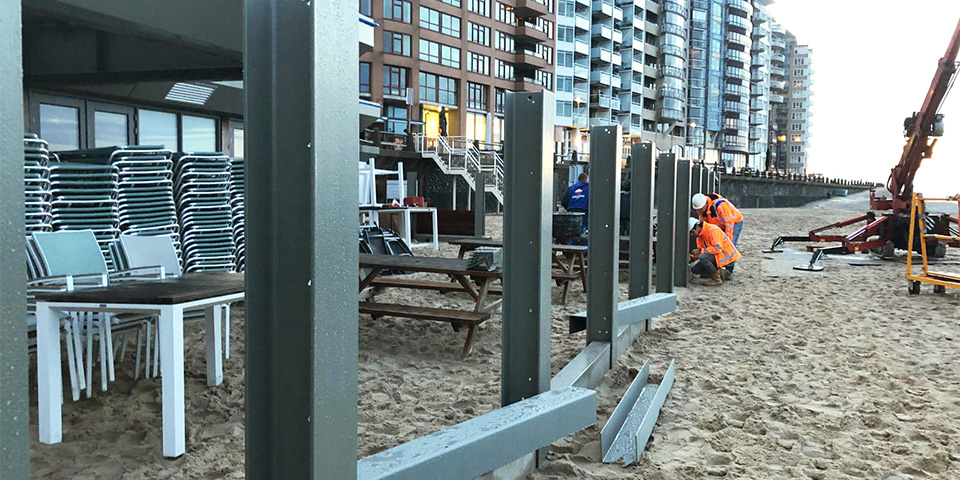

For a hospitality pavilion on the beach in Vlissingen, Aquavia is constructing a flood barrier.

Underwater drone

Aquavia's flexible nature is also evident in the various projects in which the specialist is currently involved. Buijsrogge picks out a few. "For example, we are working with VolkerWessels on a pipeline survey using an underwater drone, we are putting the finishing touches on a concrete pedestrian bridge in the Waterdunen area near Breskens and we are constructing a flood barrier at a hospitality pavilion on the beach in Vlissingen. We are also replacing the driftwood on the lock gates at Lith, replacing the lift gates and cylinders of the Bathse Spuisluis and have started the second phase of the framework renovation in Veere." Talk about a varied work package. "Also, for years we have been on 'standby' for maintenance and calamity follow-up of several important waterways and engineering structures in our country."

Aquavia recently started the second phase of the framework renovation in Veere.

Quality Assurance System

In addition to its own working vessel Ingrid B, fully equipped as a mobile workshop, Aquavia also has a professionally equipped (steel) workshop in Sas van Gent. "A year and a half ago, we initiated a certification process that resulted in NEN-EN-1090 and NEN-EN-ISO 3834-2 certification. This allows us to design, manufacture and assemble steel structures that are CE marked. The ISO 3834-2 standard is a quality assurance system for the fusion welding of metals. The 3834-2 variant is the most comprehensive variant of the certification. There are requirements for all facets of the welding process. Such as welding method qualification (LMK), requirements for welders, inspections and NDT (Non-Destructive Testing). Not only are these high requirements increasingly demanded in contract documents (legislation) in order to be allowed to tender at all, our certified expertise also allows us to move quickly in the event of calamities."