The unlimited possibilities of white cement

It all started millions of years ago. In some cases, lime was formed by the deposition of microorganisms that extracted calcium carbonate from seawater near the surface. In other cases, corals formed on the beds of shallow seas. Subsequent compression enhanced the deposits to varying degrees. High-grade marble was formed in geologically active areas.

Characteristic of all deposits in the AALBORG WHITE production process is the absence of contamination by sand and clay that could have been present if the deposits had not occurred far from large land masses. This has resulted in very pure limestone, ideal for the production of white cement. Add to this local supplies of very pure sand and kaolin, advanced technology, dedicated and experienced personnel, and more than 100 years of experience in Portland cement production, and it is easy to understand to what AALBORG WHITE cement owes its worldwide reputation for consistency and unparalleled quality.

Today, the AALBORG WHITE brand has a strong international position and is exported to more than 70 countries worldwide.

The product

The product

AALBORG WHITE cement is a fast-curing Portland cement with high early strength (2 days) and standard strength (28 days), manufactured from extremely pure limestone and finely ground sand. What makes AALBORG WHITE cement so unique are its white color, high consistency, exceptionally low alkali content and high sulfate resistance. The cement can be described by most national standards as a sulfate-resistant cement with low alkali content.

The use

With AALBORG WHITE cement you can choose any color from the spectrum to produce your concrete or dry mix. AALBORG WHITE cement is the basic color. White concrete is obtained by mixing AALBORG WHITE cement with pure, light sand and white aggregates such as white granite, white marble or crushed calcined flint. Light gray concrete is obtained by mixing with ordinary aggregates or with gray Portland cement and colored concrete is obtained by mixing with pigments.

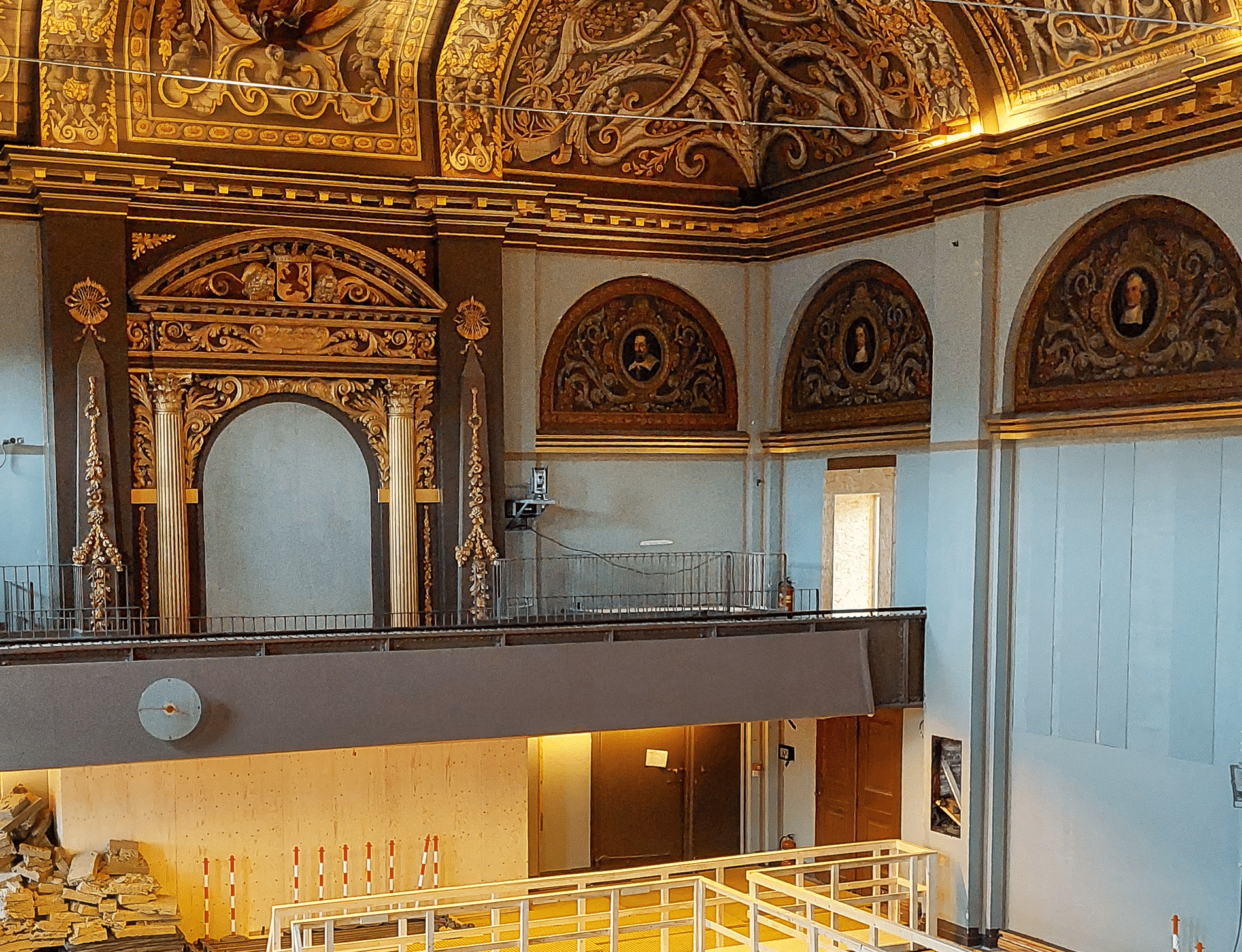

AALBORG WHITE cement is perfect for concrete for panels, balconies, cornices, ornaments, pavers and tiles, sculptures, in terrazzo, for swimming pools and in light grout. The cement is often used in white or colored dry mix for coatings. This gives a vibrant appearance that protects the masonry and meets the aesthetic sense of the viewer. The light-reflective properties of AALBORG WHITE cement provide additional road safety for concrete tires, road markings, center guides, tunnel lining and tunnel ramps.

In collaboration with MAS Architecture and Ney & Partners, URBASTYLE created a covered, concrete bench placed in the Schaerbeek neighborhood of Brussels. To achieve the right color, URBASTYLE applied a proprietary mix with white marble addition. This mix was made possible in part by the products of AALBORG WHITE. The result is fantastic!

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Aalborg Portland Belgium.

Contact opnemen

Contact opnemen