Amsterdam Van Der Valk hotel | Huge CO2 reduction thanks to new type of poured screed

The floors in the new Van der Valk hotel in Amsterdam will be finished by RM Vloeren with the so-called eco2floor, a development of Ecocem Benelux. Eco2floor combines the advantages of existing flooring technologies and is based on the use of ground, granulated blast furnace slag. This achieves significant CO2-reduction achieved.

"The traditional sand-cement screed is really starting to become a niche," says Pieter Rook of RM Floors. "It requires high physical effort and is also not particularly durable due to the binding agent cement. Good alternative now constitutes the anhydrite-bonded poured screed. However, there are some disadvantages to this, especially for the installers after us. For example, residual moisture remains for a long time, which is not conducive to the adhesion of tile work or carpet, for example. For years, Ecocem has been committed to making new construction as sustainable as possible and maximizing CO2-reduction in foundation and high-rise buildings. With eco2floor, Ecocem combines the advantages of existing flooring technologies, without the disadvantageous properties."

Future-oriented

Eco2floor is the result of years of development and experimentation. "Ground blast furnace slag, a pure residual product of the steel industry, forms the basic ingredient of the screed," says Rook. "However, it did 'take' time and trial mixtures before the right recipe was found. After all, a poured screed must be shrinkage-free and meet a certain pressure and flexural tensile strength, but also be easy to process and transport. In the meantime, we have already carried out several projects with eco2floor. It is rightly a future-oriented poured screed, not least because the raw materials are available in unlimited quantities. More and more contractors are also recognizing the benefits of this sustainable poured screed, which is walkable after 24 hours and loadable after 72 hours. We previously fitted the basement floor of the RAI hotel with some 3,000 m² of eco2floor for Pleijsier Bouw. The great results there prompted Pleijsier Bouw to apply this poured screed in the new Van der Valk hotel as well."

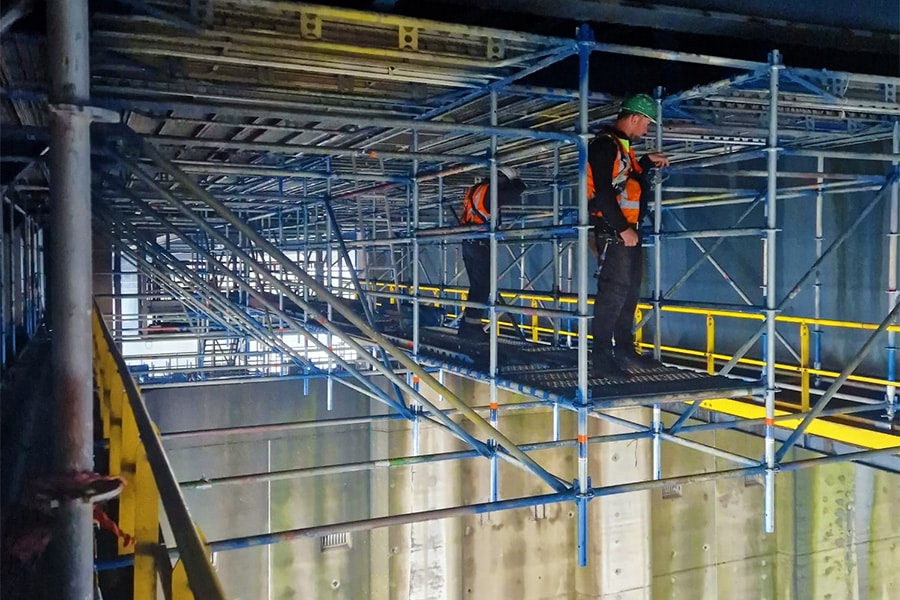

RM Flooring applies eco2floor in an Arbo-friendly manner (standing) in stages.

Health and Safety Friendly

The Van der Valk hotel in Amsterdam is being built under BREEAM certification. "Since eco2floor will be used for over 13,000 m² here, a significant saving in CO2-emissions realized. Thanks to the ground blast furnace slag, CO2-emissions from this screed are very low." RM Floors applies eco2floor in an Arbo-friendly manner (standing) in phases. "Every fortnight we deliver a floor. According to schedule, we will be finished just before Christmas. Because eco2floor has a much better drying behavior compared to anhydrite and 'eats up' the water, as it were, instead of 'sweating it out', the floor can be laid considerably faster. In fact, Eco2floor no longer needs to prove itself, because the world behind us is raving about it. We have already installed about 150,000 m² of eco2floor over the past 2.5 years. The product is by no means yet fully developed and has many more applications. In the background, we are working on recipes with even higher compressive and bending tensile strength."