Amsterdam Van der Valk hotel | Puzzling with 850 tons of rebar

The first Van der Valk hotel in Amsterdam is immediately also a feat, both aesthetically and technically. Balvert Betonstaal shed light on the unique prestressing method, the additional reinforcement for the first seven floors, and translated it into a comprehensible and feasible whole.

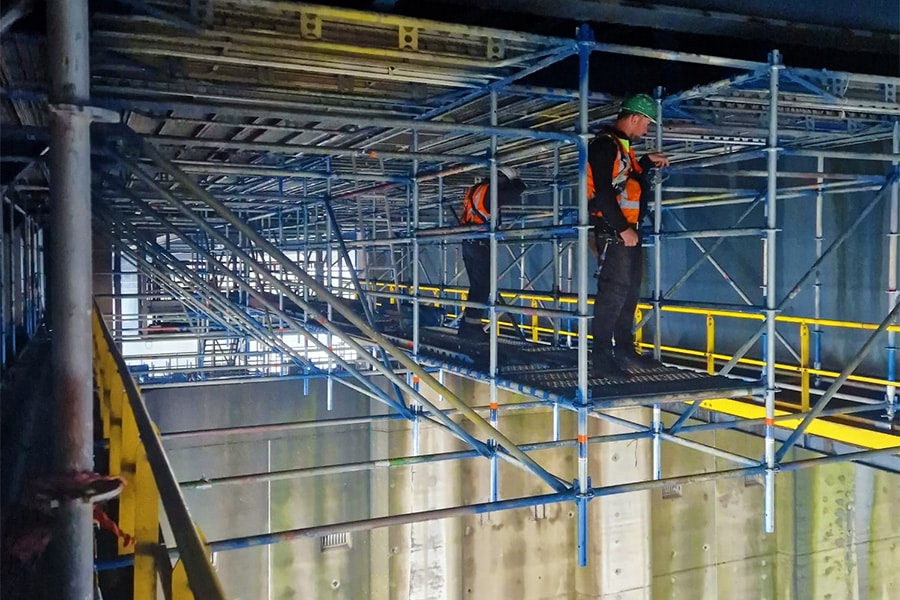

The first seven floors of the hotel are poured on site, while the superstructure (the hotel rooms) will be constructed in prefabricated elements. "The structural design of the first seven floors comes from a British engineering firm," says Robin Aantjes of Balvert Betonstaal BV. "It is the first time it has been applied in this way in the Netherlands. In this case it was chosen because of weight savings and being able to make the floors thinner. We were commissioned by Van Muijen Betonbouw to review the reinforcement drawings and translate them into a feasible whole."

The total project including the wall reinforcement includes 850 tons of rebar.

Finetuning

Balvert Betonstaal has specialized in the supply and processing of reinforcing steel for 54 years. This is done from a modern, very neat-looking reinforcement plant located in Nieuwkoop. According to Aantjes, the British engineering firm's drawings still needed some fine tuning because some things were difficult to realize in practice. In particular, he refers to the combination of tension cables and punching reinforcement (reinforcement baskets) around the columns. "Each column (25 pieces total) is provided all around with seven to nine reinforcement baskets, mostly different in size, and attached to a bottom net. The edges of the floors are fitted with hairpin baskets and the tension cables are placed on top. What is unique - by Dutch standards - is that no top reinforcement was used. It is inherent in the chosen construction, but admittedly still takes some getting used to, also for our braiders."

Robin Aantjes, work planner at Balvert Betonstaal BV.

Working well

During execution, according to Aantjes, it was especially careful to apply the right baskets around the columns. "In the engineering phase we already took this into account with extensive bending lists and reinforcement baskets, all numbered of course." Fehmi Guler, foreman of the rebar workers, can attest: "It was really a very laborious pit for us. This was not only due to the unique British-made prestressing method, but also because of the shape of the building. The sharp corners (design: triangular hotel) also made the braiding very laborious. We spent a year working with fellow reinforcing steel fabricators on the project." Even though no traditional top mesh was used, there was still a serious amount of no less than 512 tons of reinforcing steel incorporated into the floors. And that's only in the first seven storey floors. "As a result, the storey floors are relatively thin: 280 millimeters. Only the transition floor, the seventh floor, differs considerably with a thickness of 90 centimeters," says Aantjes. "In this floor, top reinforcement has been applied. Which makes sense, since it forms the basis for the entire superstructure. The total project including the wall reinforcement includes 850 tons of reinforcing steel."