When an expert in steel and zinc undertakes a project

At a hot-dip galvanizing plant, one can ask questions about hot-dip galvanizing, but not about welding. With a construction company it is the other way around: they know the welding process but are unfamiliar with hot-dip galvanizing. Thiekon Constructie BV masters both areas: it is a construction company with its own hot-dip galvanizing plant. The unique combination of knowledge and expertise in the field of steel and zinc means added value in the development of each project. Especially since Thiekon Construction also provides the welding of rebar under KOMO.

Thiekon Constructie BV from Rijen has over forty years of experience in steel and zinc for residential and commercial construction. "As the only construction company in the Netherlands, we have our own hot-dip galvanizing plant. Our expertise in both areas allows us to advise building partners well and help them save costs. Our team designs, produces and assembles customized solutions, from thin shims to complete steel structures. We are certified for the highest execution level for steel structures (EXC4) according to the EN 1090 standard and chose KOMO certification for welding reinforcing steel," explains engineer Neil Wan. "Our two trades are also covered by different standards of the Building Code and Eurocodes. Steel construction standards look at the design and execution of steel structures. For rust protection, there are requirements related to service life."

Life expectancy of 100 years as a challenge

As an all-round expert in steel and zinc, Thiekon is involved in a wide variety of projects. For example, the specialist supplied all hot-dip galvanized, KOMO-certified pouring consoles for the new building of the RIVM (National Institute for Public Health and the Environment) at the Science Park in Utrecht. For the prefabrication of the concrete floors in the new construction garage on the Garenmarkt in Leiden, they also supplied all the in-situ brackets. "The specifications for this project specified a life expectancy of 100 years," describes Wan. "We studied the site carefully and considered how the environment and surroundings would affect the structure. We also took into account the Eurocode and other standards. In the end, we issued that extremely high life expectancy."

Consoles untreated and hot-dip galvanized.

Contribute to the optimization of project descriptions

With every project, the team at Thiekon thinks fully along with the construction partners. A project in Amsterdam required hot-dip galvanized, powder-coated elements and a 50-year service life. Thanks to the innovative galvanizing process described in 2018-2 of Concrete and Steel Construction's hot-dip galvanizing, the company was able to offer a solution that fully met expectations without the need to powder-coat the pieces. "For the new construction project De Groene Kaap on Katendrecht in Rotterdam, we are supplying all the heavy hot-dip galvanized brackets for the balcony suspensions," Thiekon's engineer continues. "The original design included very heavy, expensive welded connections. During the quotation phase, we looked with the chief structural engineer at how those welds could be made lighter. Eventually we developed a production proposal with thinner plates and thinner welds, which was approved. We were awarded the contract and thus were able to help save costs."

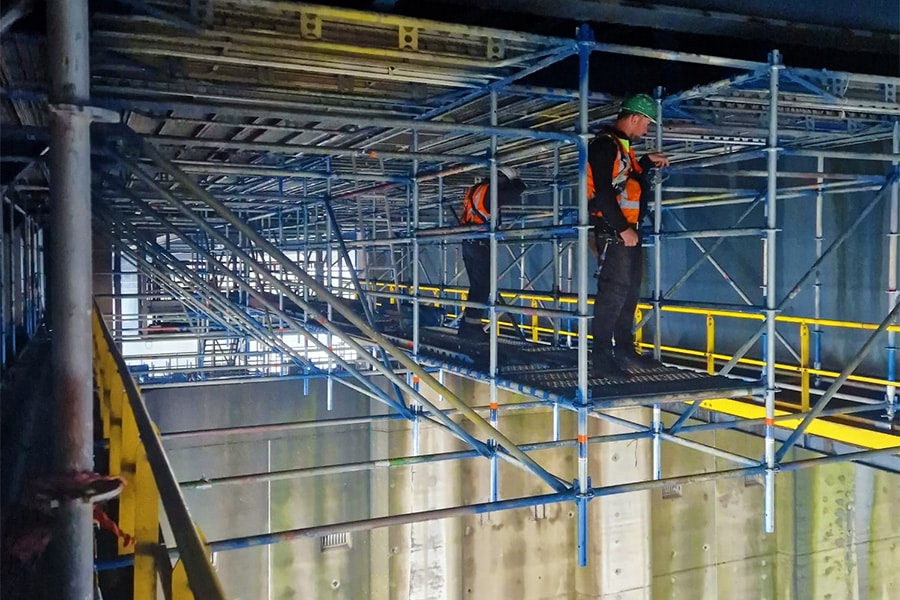

Foreign projects as well

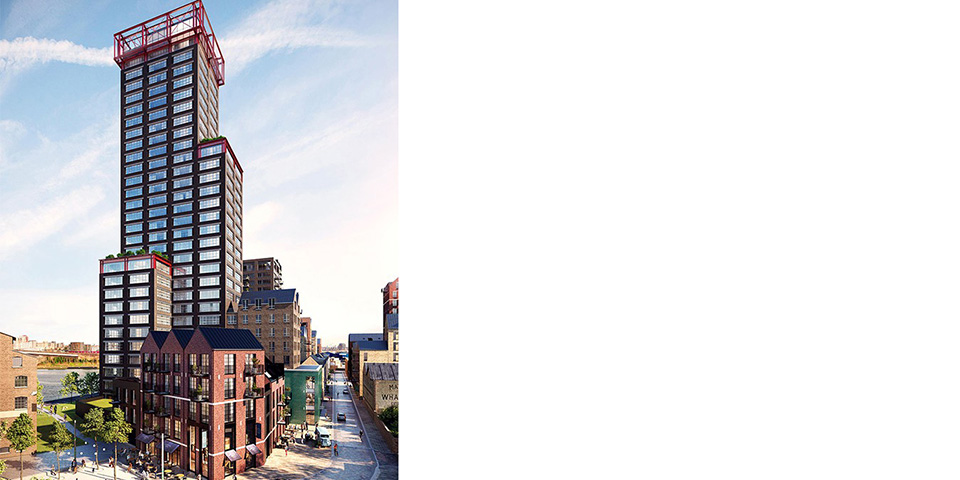

Thiekon also collaborates on projects abroad. For example, the firm produced and supplied welded, hot-dip galvanized and 2-layer powder-coated KOMO-certified pour-in brackets for suspending balconies for the Douglas Tower (Good Luck Hope), a skyscraper in the heart of London. "We worked closely with a precast concrete builder from Veldhoven on this project," concludes Neil Wan. "They saw in us a quality extension for the load-bearing welded hot-dip galvanized KOMO components, so they could focus on their core business: working in concrete."

Douglas Tower in London for which Thiekon Contructie BV supplies all balcony brackets.