Construction team chooses steel plate concrete floor

New storey floors for Van Gendt Hallen

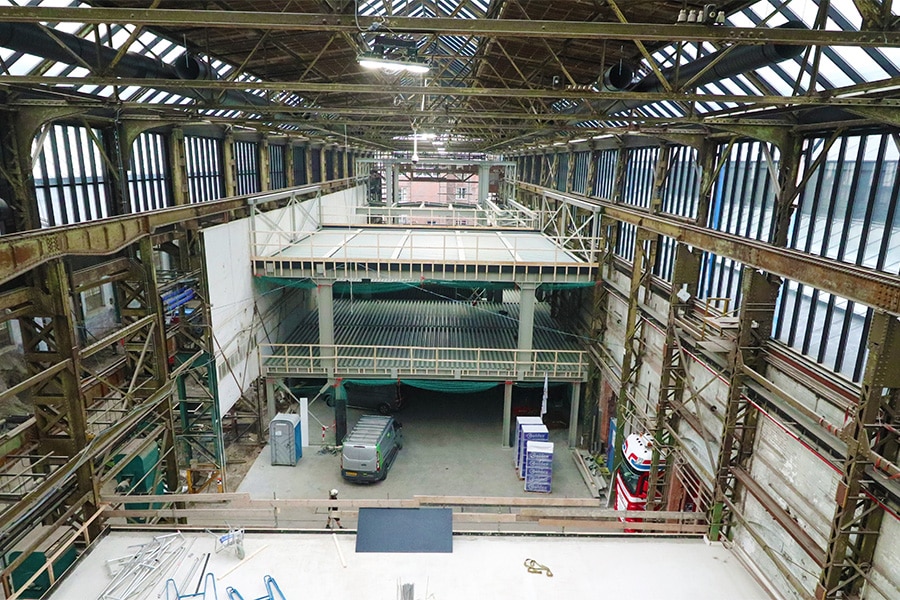

The 19th-century Van Gendt Hallen will be given a modern interpretation after years of vacancy. The Drift Museum, restaurants, offices, start-ups and more will move into the five majestic halls. To make this variety of new functions possible, 13,000 m2 of new floors were constructed. Steel builder Vic Obdam engaged Tullingh & Partners of Dordrecht to do this. "It is of course a beautiful, extensive assignment, but especially the particularly fine cooperation and atmosphere make this a fantastic project to work on," said Charles van Oldenbarneveld of Tullingh & Partners.

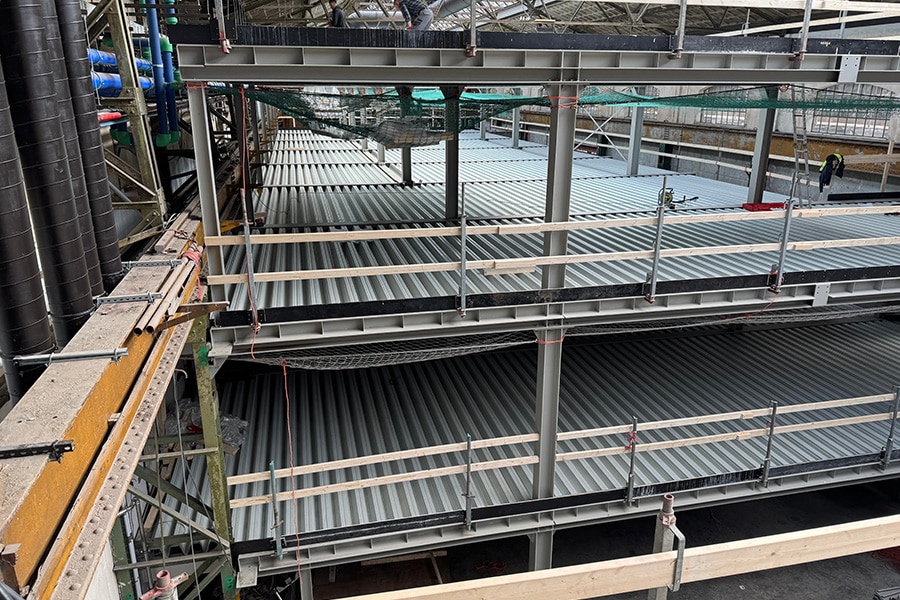

The construction team decided early on to design the floors with steel plate concrete floors. This versatile floor type is increasingly used in new construction and renovation projects. Van Oldenbarneveld: "Due to the wide choice of profiles, profile heights and thicknesses of the steel plate, steel plate concrete floors can offer an enormous diversity of solutions with spans up to more than eight meters. With minimal use of concrete, floors are possible that are relatively thin, have a low deadweight and yet are highly loadable. That weight was also an important factor for the Van Gendt Hallen construction team in choosing this floor system. Applied on this scale, you can build floors with a significantly less heavy steel structure and foundation. In addition, using less concrete is more sustainable, an important issue in this transformation. Another big advantage is that you are dealing with an existing, not easily accessible building project. Working with easy-to-handle steel plates goes much more smoothly in such an environment."

One type

Because of the many different functions that the Van Gendt Hallen will house, the different storey floors are built with spans ranging from 3.5 to 8.6 meters and floor loads ranging from 3.7 to 5.5 kN/m2. "Nevertheless, the same type and design of steel plate concrete floor was chosen everywhere," Van Oldenbarneveld continues. "Only in the larger spans there is more and heavier reinforcement. The reason is that the ceilings remain visible everywhere and had to have the same aesthetic appearance. Therefore, we have already applied a dark-gray primer to all the steel plates in the factory, which will be finished with a black coating in the Van Gendt Hallen. Standard galvanized steel sheet is too greasy for this finishing process."

Dosed

In addition to reinforcement bars and nets, the floors also include pipes for the underfloor heating and cooling used to condition all rooms. This brings the total thickness of the steel plate concrete floors to 24.5 cm. "Which type is ultimately applied is of course project-dependent," Van Oldenbarneveld explains. "Our structural engineers look at the span, what the load is, the own weight, the fire and insulation requirements and the practical implementation. Then a recommendation for the client follows and the system is incorporated into the structural design. Logistics was also very important here. The 13,000 m2 of steel floor sections were produced and delivered in doses, according to the phasing of construction. In connection with hanging safety nets in the steel structures, as many packages of steel plate as possible were already brought to the desired level in advance. Incidentally, the roof of the so-called trestle was also made with our steel plate, but without concrete and with insulation."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Tullingh & Partners BV.

Contact opnemen

Contact opnemen