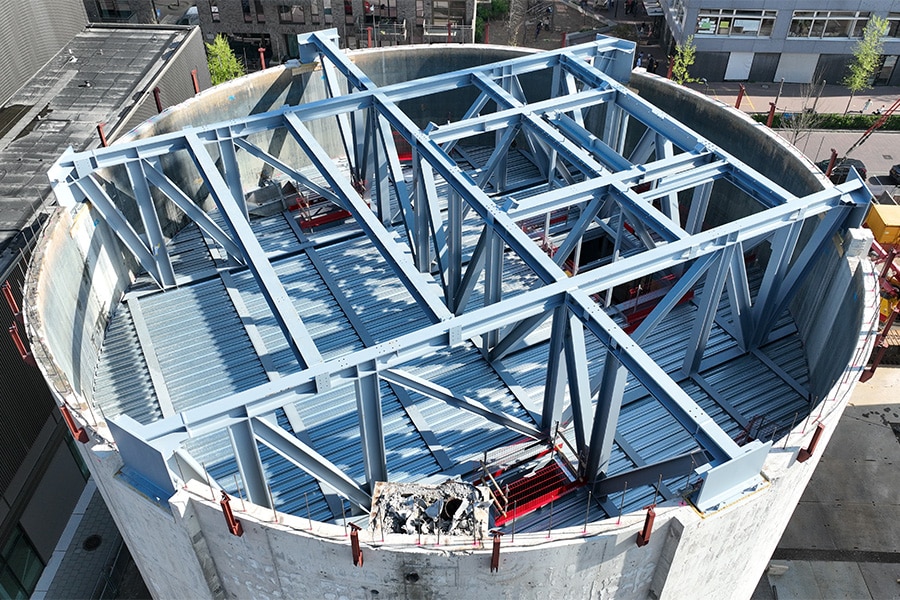

Thorough preliminary work

Construction site Silos Zeeburgereiland

Back in 2020, Bonneveld Aannemingsbedrijf BV received the request from Vink Bouw to help think about the construction site on Zeeburgereiland. Not a complicated job, but different because the site lies around three silos to be transformed and in the middle of a residential area. Corona, canceling parties and other inconveniences caused delays, but in the fall of 2024, the earth-moving company could finally get to work.

"Of course you prefer to get to work right away, but some circumstances you can't force," begins Bonneveld technical director Stefan Albers. "The assignment was straightforward. The topsoil had to be excavated 30 centimeters and filled with mixed granulate, and a roadway was needed for a heavy crawler crane. On the 5,000 m2 construction site, however, space around the silos was limited. To make room for a chain park across Leo Horn Street, the waterway was partially filled in with soil from the building lot."

Surroundings

"On that side also came the construction entrance," continues Sander Bos, head of calculations for the Bunschoten family business. "This prevents inconvenience and dangerous situations on the other sides. After all, next to the construction site are schools, a daycare center and a sports hall. The work itself is not earth-shatteringly complicated. Vink Bouw took care of the permits and coordination with the municipality to drain the waterway during the construction period. This made it possible to realize the chain park and a parking lot. We ensured water transit by constructing a temporary culvert. Rubble pavement and floor slabs form the basis for the construction chain and parking lot."

Flat roadway

Although in fifty years Bonneveld has grown into a versatile specialist in ground, road and hydraulic engineering, major earthmoving was not necessary for this project. Albers: "The old installations of the sewage treatment plant had already been demolished some time ago during a remediation round. So you don't come across old foundations anymore. It was a matter of excavating, making an even driving surface of 30 centimeters of mixed granulate, applying floor slabs and laying bulkheads for the crane."

Reuse

The transformation of the silos is a project with high sustainability ambitions. The design certificate BREEAM Outstanding has already been obtained and the implementation is also along a strict sustainability line. Bos: "We are doing our bit, literally and figuratively. Part of the rubble granulate comes from a crusher in the neighborhood, a significant part comes from Delft from another job of Vink Bouw. At the end, we are going to clean up the construction site. Rubble granulate then goes on to another construction site and if there is no room for it, to the crusher. Floor slabs that are good enough, we also use them for as long as possible. Once the construction hut is gone, our last work will be to restore the waterway to its former state and fill the construction site with the soil. Around the silos there will be greenery with terraces, so I'm sure that will be very nice!"