Hybrid reinforcement applied at Grotius project in The Hague

Engineers and contractors are increasingly choosing hybrid reinforcement (traditional reinforcement combined with steel fiber reinforcement) to better reinforce parking garages and basements of apartment buildings and offices against water pressure. In this way, the crack width of a structure can be monitored and controlled more efficiently. This is also the case with project Grotius in the center of The Hague, where two residential towers of 110 and 126 meters high are being realized by the construction combination J.P. van Eesteren and Besix.

Traditionally, steel fibers have been used mainly for industrial floors and prefabricated tunnel segments. In recent years, the publication of some local and international standards and the development of new fiber types - with greatly improved performance - have greatly widened the field of application for steel fiber concrete. This has allowed steel fibers to make their appearance especially in more structural applications, such as foundation slabs, walls of underground parking garages and cellars of residential towers. There is always water pressure against the bottom of the foundation slabs of parking garages and basements of residential projects, due to the depth of these structures and the level of groundwater. This can obviously be quite high since the groundwater level is generally within 2 meters below ground level in the Netherlands. Thanks to the addition of steel fibers, the amount of traditional reinforcement can be greatly reduced and cracks can be controlled more efficiently.

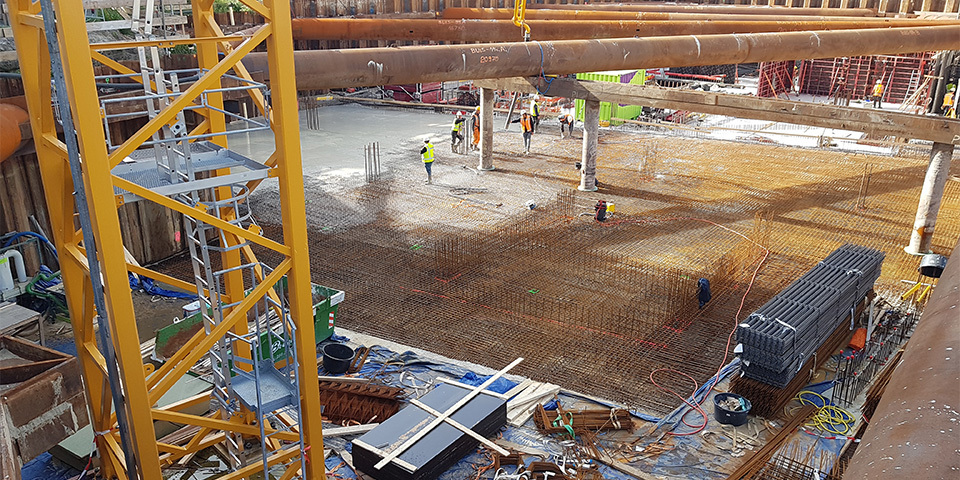

Because of the size of the project, the pouring of the steel fiber concrete was carried out in several stages.

Technical challenge

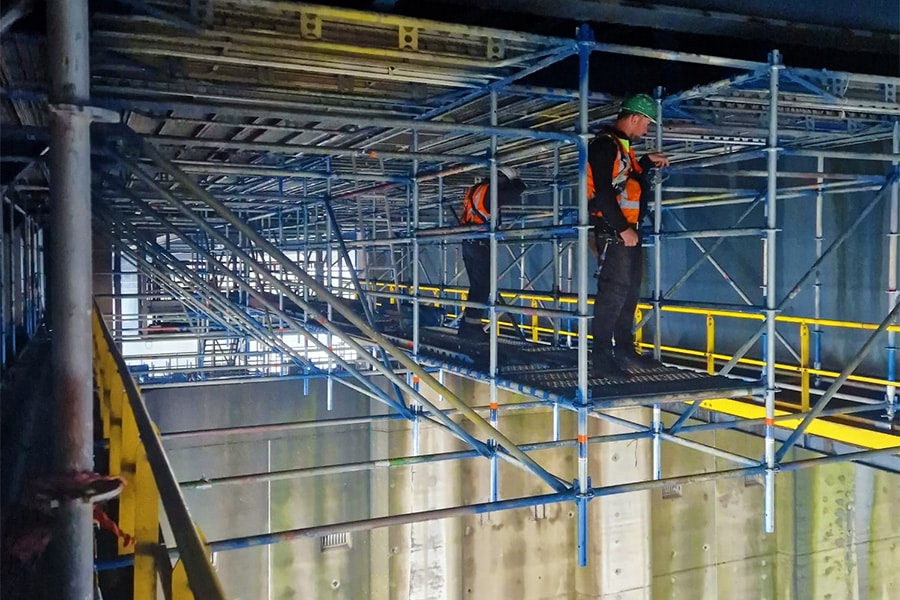

In the Grotius project, ensuring the watertightness of the 300 and 400 mm thick foundation slab, which also serves as the lower floor of the parking garage of the residential towers, was a technical challenge. Traditionally, a base reinforcement of Ø16 bars, spaced 100 mm below and above, would be provided. However, the addition of up to 30 kg/m³ Dramix 4D 65/60BG allowed the reinforcement to be reduced to nets Ø12-100, resulting in significant savings in both material and labor. It is important that the pouring and processing of steel fiber concrete is carried out by a (flooring) company with sufficient experience. The hybrid foundation slab was poured and floated monolithically.

Crack Control

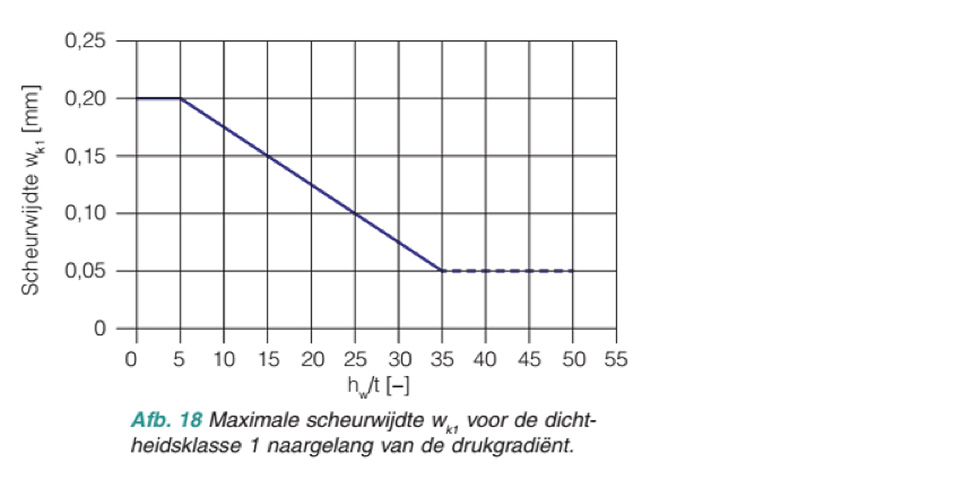

The tensile strength and anchorage of the Dramix 4D steel fibers were specifically developed to control cracking and, in combination with traditional reinforcement, limit crack widths between 0.1 and 0.3 mm to create a durable and fluid-tight construction. These types of fibers, which have KOMO certification, offer the highest flexural tensile strength in the service limit state (SLS) within the Dramix® steel fiber range, tested in accordance with EN 14651. The steel fibers are homogeneously distributed in the concrete slab. With hybrid reinforcement, more cracks occur but because the total crack width remains the same, those crack openings are much smaller and finely distributed, creating a watertight construction. From the moment a small crack occurs in the concrete, it will immediately be bridged by a fiber. With traditional reinforcement, although there are fewer cracks, in order to achieve - with equal overall deformations - the same crack width, much more traditional reinforcement is needed than in the case of a hybrid reinforced construction.

Source image: TV 247 - Technical Information 247, Design and construction of Liquid-tight concrete structures, WTCB (Scientific and Technical Center for the Construction Industry), 2012.

Popular

In recent years, hybrid constructions have been increasingly used. Bekaert not only supplies the required steel fibers, but also offers technical support during the design and implementation process, by determining the most suitable fiber type, the optimal dosage and the relevant concrete quality, for a wide range of applications. The application of steel fibers has many advantages, especially in terms of material cost, labor, placement and time.