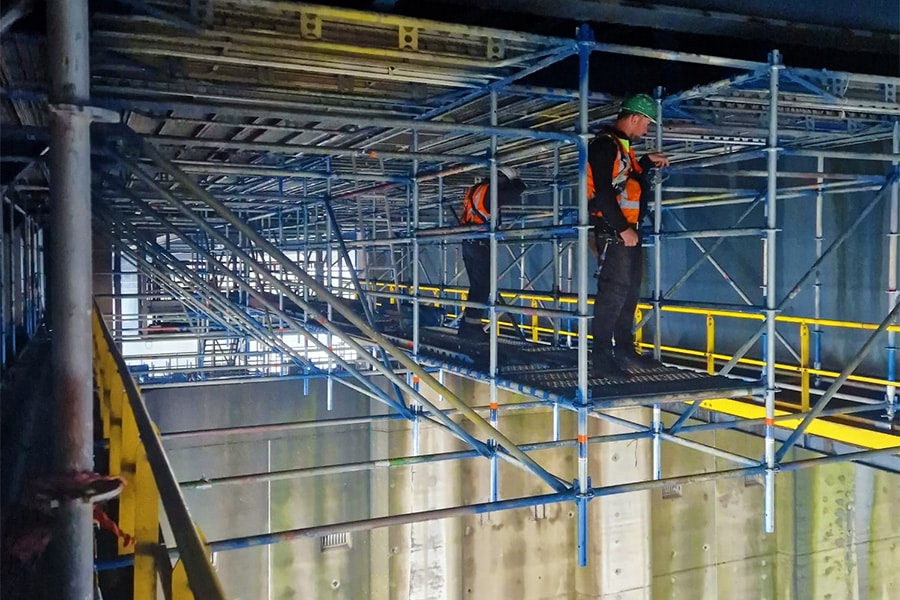

Suspended scaffolding at bridge renovation: craftsmanship in practice

Suspended scaffolds are often essential for bridge renovation and maintenance. After all, they provide safe and efficient access to the underside of the structure. This was no different with the recent renovation of the Van Brienenoord Bridge. Scaffolding contractor ESS Scaffolding was commissioned by KnookStaal to deliver a true work of art under the bridge: two suspension scaffolds, each 53 meters long, also fully covered and lined to prevent possible debris from ending up in the water.

ESS Scaffolding is no stranger to the Van Brienenoord Bridge. "After previous successful implementations, a new tender followed, in which we were again chosen. A confirmation that our approach was well liked," says Wesley Vergouwen, who owns ESS Scaffolding with his brother Stefan. "The purpose of our construction was to make the wooden beams of the east valley safely accessible for the work of KnookStaal and Straal- en Schildersbedrijf Feijenoord. The scaffolding structure was supported on the outer sides on the bridge's landings, while in the middle it was suspended."

53 meters long

Based on the technical drawings of the underside of the bridge, ESS Scaffolding's team created a concept design for the two scaffolds: one on the outside of the east trap and one on the inside. Both 53 meters long and 4 meters high, but 4.5 and 8 meters wide, respectively. "The drawings were then submitted to our regular engineering partner, who performed the calculations to ensure load capacity and safety. Factors such as wind load, load on the work floor and the closure of the floor with plates and shrink wrap were included," explained Vergouwen. The work floor itself consisted of steel grids, planks and wooden boards that were tightly fitted together. The walls were carefully sealed with fire-retardant shrink wrap. This created a closed and safe working area, so that paint and grinding residue could not end up in the water.

Complex logistics

The biggest practical issue is often not the construction itself, but the logistics: how do you get all the materials to the bridge in the right place? This requires careful planning, experience and a good dose of creativity. After all, the essence of a suspended scaffold is that it is not erected from the ground, but is suspended from the supporting structure of the bridge. This involved beam girders being attached to the cross girders and trusses. Vergouwen: "The suspended scaffold was assembled using a telescopic handler with a work bucket that was set up on a pontoon under the bridge. The work bucket was always supplied with scaffolding material and went up with two mechanics to assemble the hanging section."

The great added value of ESS Scaffolding in this type of complex project is the combination of in-depth know-how, built up over generations, and a flexible organization that can move quickly. "Moreover, special parts that are not available as standard can be custom-made in cooperation with suppliers. An example of this is the unique length dimensions that we had specially made for the IJssel bridges in Arnhem," says Vergouwen. "Whether for pre-planned renovations or ad hoc emergencies: our teams are ready to install scaffolding within a very short time and, if necessary, even the same day."