Trusses at height

1,500 tons of steel for transformation silos

Coming up with an exciting steel structure for the transformation of three old silos on Zeeburgereiland is one thing, but it also has to be executed. That task was entrusted to Buiting Staalbouw, which provided full 3D modeling and detail engineering. This in close cooperation with Pieters. Buiting is expected to complete the shell construction around the construction period.

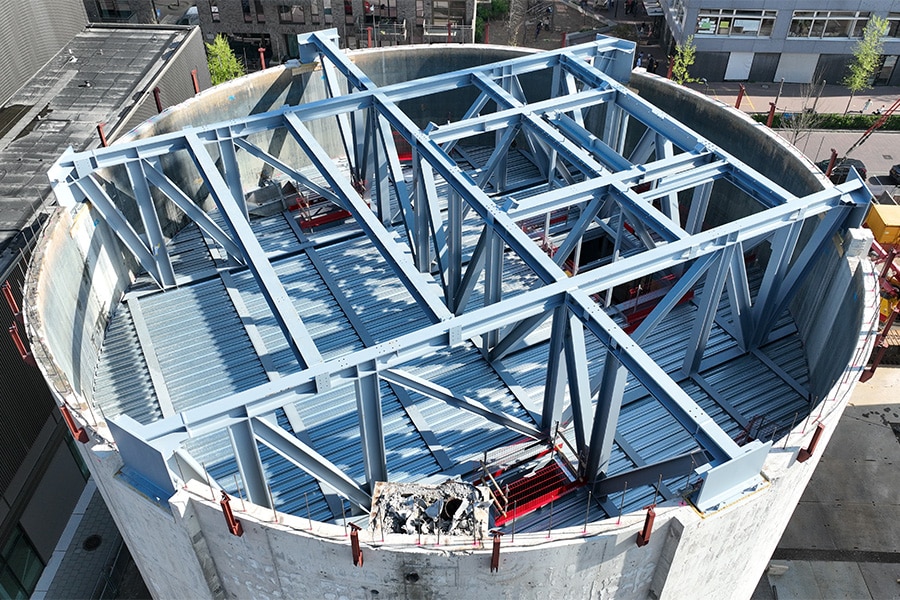

Pieters' structural design (see previous article) includes an interior steel structure in the lower levels of the silo, a table structure with lattice trusses resting on the silo wall, and a 20-foot-high optop. The topping of the three silos is identical, the incorporation differs and is tailored to the future user. "The work is being done in phases across the three silos, each time alternating steel construction with concrete pouring," says Peter Hoff, project manager for Buiting Staalbouw. "We start each silo by installing the structure for the lower layers. The floors on the lower levels are supported by shoes and brackets on the silo wall and by columns on the first floor. A rise point with one or two elevators also runs through these floors. Above the built-in floors is another interior layer, but it is part of the heavy truss construction."

Phased

The truss construction is the heart of the structural design. Hoff: "It carries the entire twenty-meter-high superstructure. To this end, 5.5-meter-high lattice trusses weighing over twenty tons were installed, spanning the entire silo. This structure rests on the six piers of the silo with an underlay plate. Once the truss construction is in place, we continue with the truss of the next silo so that contractor Vink Bouw can reinforce and pour the underlying steel plate concrete floor. In this way, we work in phases from silo to silo. Outside, Van Marwijk's 160-ton crawler crane patiently drives back and forth with this phasing."

Stability

With the table structure in place, Buiting can continue to build on the superstructure. Hoff: "The riser core is made of composite frames that together form a tube of twelve by five meters and provide stability. Around this we are building a hall structure and the three office floors that will soon reach a height of forty meters. Laying all the steel plate concrete floors is also part of our assignment. Engineers from Buiting determined the different types of Comflor based on Pieters' design. For efficient on-site assembly, we try to tailor the plates as much as possible at our production sites in Almelo and Broekland. Not unimportantly, this floor system allows you to build without stamping and the poured floors are strong enough to support aerial platforms."

On-site assembly

In total, Buiting is processing approximately 1,500 tons of steel and 6,600 meters of Comflor steel plates on this project. "Assembly takes place for the most part on the construction site," Hoff concludes. "Only the trusses, with their size of twenty by 5.6 meters, fall under the category of special transport. April saw the first of three night transports from Almelo to Amsterdam, the last is expected to take place at the end of May. After the construction period, we hope to complete our work."