Working together on constructive puzzles in repurposing silos Zeeburgereiland

In 2006, a new plant in the Westelijk Havengebied took over the duties of Sewage Treatment East on Zeeburgereiland. Since then, the Sportheldenbuurt has been developed on the site. Most of the silos have been demolished and only three large silos remain as reminders of the old RWZI. Many rezoning plans pass the revue over the years, then in 2017 the plan "Three Kings" by Vink Bouw Nieuwkoop and Grayfield Management gets the green light from the municipality of Amsterdam. In a design by architectural firm Elephant, the industrial heritage will be converted into multifunctional facilities and topped off with an impressive superstructure. Pieters was allowed to grit its teeth on this constructive challenge.

In the redevelopment process, several variants passed by as destinations, including a hotel. But the end result will be a multifunctional facility package that will be a nice addition to the new residential neighborhood. In the westernmost silo, Rialto will operate a movie theater, the middle one will house a gym and the eastern silo will have a restaurant. These three functions will be connected with an existing walkway at a height of 25 meters as a roof park. Office spaces are planned in the upper layers.

19 meters of sediment

Constructively, this repurposing contains some interesting solutions. These mainly have to do with adapting a structure to the changed loads and how to transfer these to the foundation. Pieters, already involved in the tender phase as a structural engineer, was allowed to solve this puzzle. "The starting point was three 1978 silos that were 19 meters high and 21 meters in diameter," begins Tim Kooij, structural engineer for Pieters. "They were built as settling tanks, with a 50-cm-thick floor on a pile foundation in a concentric pattern. The walls are concrete and 35 cm thick. The horizontal forces are absorbed in the wall throughout its height by prestressing cables anchored at six positions in thickeners with spiral reinforcement. As a result, each silo has six vertical thickenings or piers. Surveys in 2017 and 2023 showed that the quality of the structures was good."

Redirecting forces

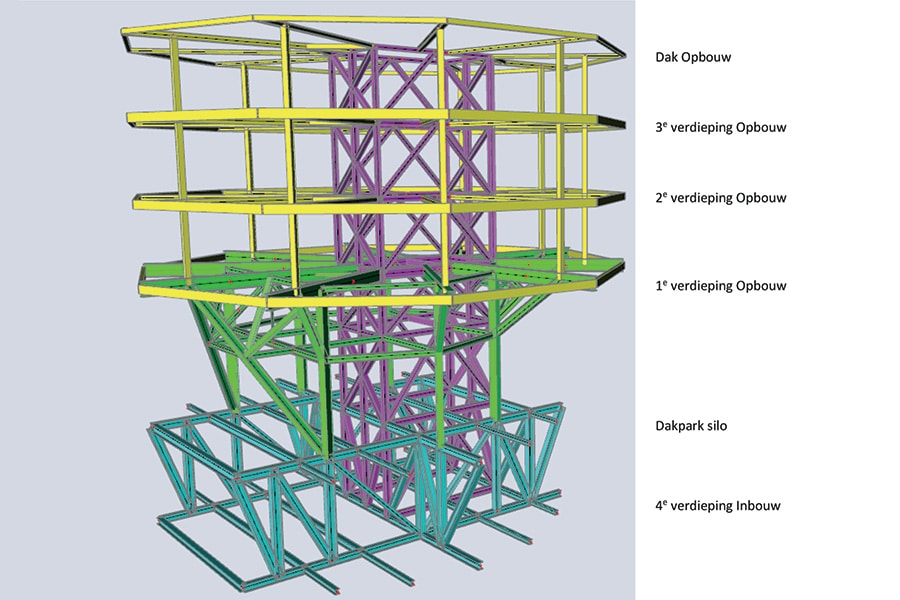

With these starting points, Pieters had to look for ways to make the silos suitable for their new functions, with the optopping in particular bringing new loads. Kooij: "You go from a uniform floor load of 66,000 kN of sediment to an topping that we had to support almost entirely on the silo wall. We therefore designed and engineered the same steel structure for the three silos together with Buiting Staalbouw. The basis is a table structure that rests on the six piers with a five-meter-high truss underneath. On this basic structure rest the steel stability core and a hall structure on which in turn the three office floors stand. Thus, the bulk of the forces are transferred to the silo wall; the rest passes from two columns below the core structure with the risers. The table structure is at the level of the future roof park, which will be connected by walkways. Then you can catch a movie on the other side after a bite to eat."

Collections

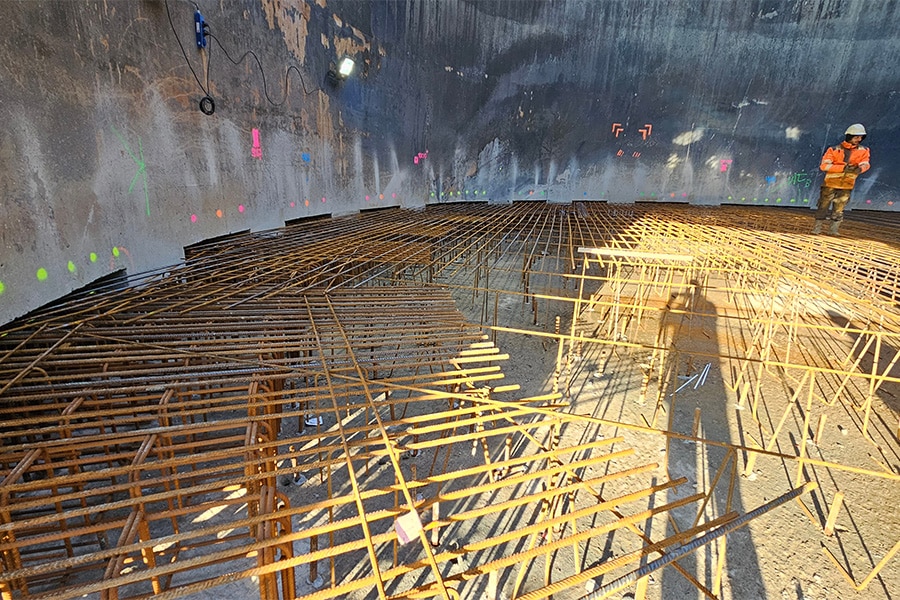

Without additional structural measures, almost all of the load would fall through the wall onto the piles directly below. To address the other piles as well, a large number of recesses were cut at the bottom of the wall and a 70-cm-thick floor was poured on top of the old floor. Studs ensure that the old and new floors work together constructively. Kooij: "Through the notches we achieve that the silo wall also rests on the new, now 120 cm thick floor. Sawing was not easy because the wall is 35 cm thick and at the location of the pins even more than 60 cm. Fortunately, the prestressing strands are attached through and through, so we could simply pull them through. Through the notches and reinforced floor with heavy reinforcement, we pull the load from the wall inward. The columns under the core structure are on anchored base plates on the new floor. In the end, it's about not exceeding 66,000 kN with the total load, and we succeeded."

Cinemas

Meanwhile, the recesses have been installed, the floor poured and the steel structures placed in the silos. In early April, the first truss was lifted into place. "This heavy 5-meter-high truss allows two column-free cinema halls to be built in," Kooij explains. "This silo has floors inside the silo that will house smaller theaters. The storey floors are attached to the silo wall. We use Comflor 95 and Comflor 210 steel plate concrete floors for the floors. This also applies to the sloping cinema floors on which the seats are placed."

Crescent Moon

Constructively, the silos with the gym and the restaurant are elaborated in the same way as silo West with the cinema. The restaurant is different in that one floor is shaped like a half-moon. There will also be an extra elevator for goods transport. At the gym, at the request of the operator, it has been ensured that a continuous wall remains free for the placement of sports equipment. "All in all, this is a fantastic project and there will soon be a beautiful complex here," Kooij concludes enthusiastically. "This kind of repurposing is just really fun puzzles, which as a structural engineer you solve together with the client, users, architect, contractor and suppliers."

Steel plate concrete floors for silos

All storey floors of the silos will be filled in with ComFlor steel plate concrete floors. For structural engineer Pieters, there was ample reason to incorporate this system from Dutch Engineering into the design. "In the first place because of the freedom of form that ComFlor offers," explains Wiebren Wind of Dutch Engineering. "The buildings are round, a number of floors are sloped and there are many interruptions by steel structures; that is a lot harder to execute with hollow-core slabs. Moreover, the total weight of the new structure plays a big role. That's where ComFlor's lower own weight compared to the alternatives worked in our favor. A third argument is that the contractor can work stamp-free with the chosen steel plate concrete floors."

Buiting Staalbouw, responsible for the overall steel structure, is processing three types of steel plate concrete floors. Wind: "For the incorporation of the silos and the cinema floors, this involves 2,700 m2 of ComFlor 95 and 300 m2 of ComFlor 100. For the office floors in the silo structures, 5,400 m2 of ComFlor 210+ will be used. The latter is our updated type with a profiling that makes the steel sheet function even better as bottom reinforcement. This makes larger spans possible. Because of the hidden fastening, you can also leave them in sight." The steel plates are produced in Zoeterwoude. The plates are fully customized using a cutting robot in Buiting's factory. This benefits the lead time in execution.