Belgian concrete hollow-core slab producer further establishes profile in Dutch market

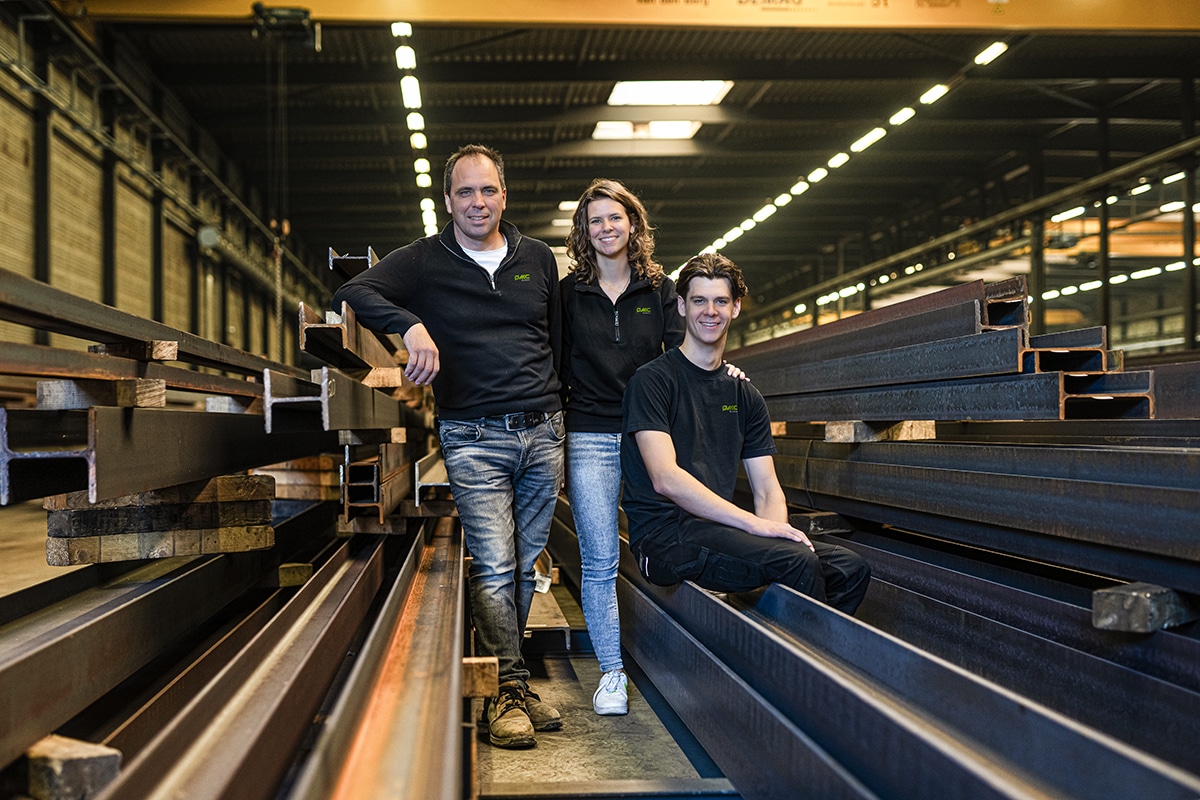

Fingo, with four branches in Belgium and sales offices in the Netherlands and Germany, has become a leading player in the production of pre-stressed and reinforced wafers in its nearly eighty years of existence. Over 25 years ago, the company entered into a close cooperation with i-Theses for the digital optimization of its production processes. A further profiling in the Dutch market is now in full swing.

From ad hoc to continuous collaboration

Gert Van Cauwenbergh, managing director at Fingo: “The cooperation with i-Theses started with the implementation of a drawing program for drawing up laying plans. Afterwards, the automation was gradually extended to almost all production-related processes, with the exception of purchasing and accounting. Each extension came about on the basis of a concrete demand from our company. For administrative bottlenecks in the production process, i-Theses always developed a suitable software solution. This pragmatic ad hoc approach evolved into a day-to-day cooperation with a clear competitive advantage and currently allows Fingo to tackle the Dutch market with even more clout.”

Software-based nervous system

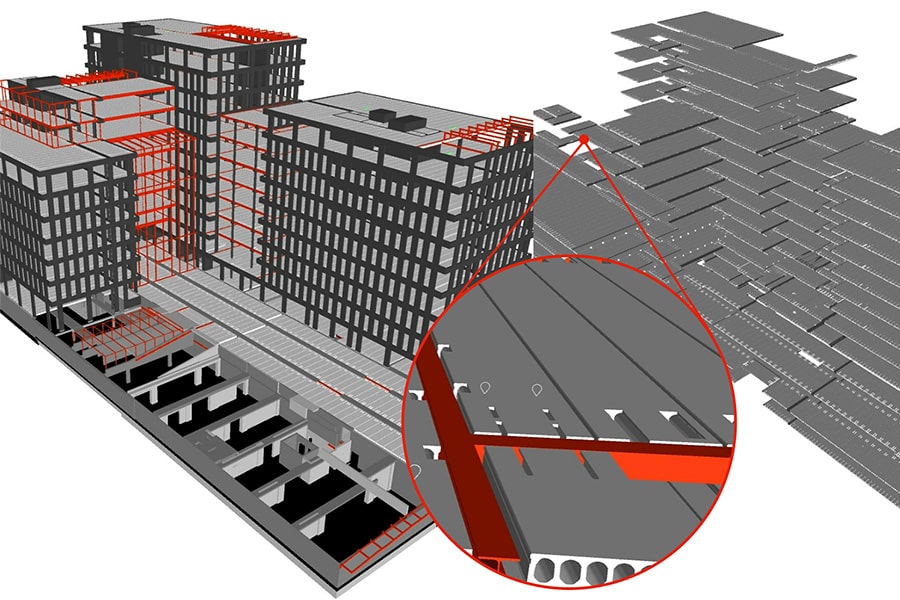

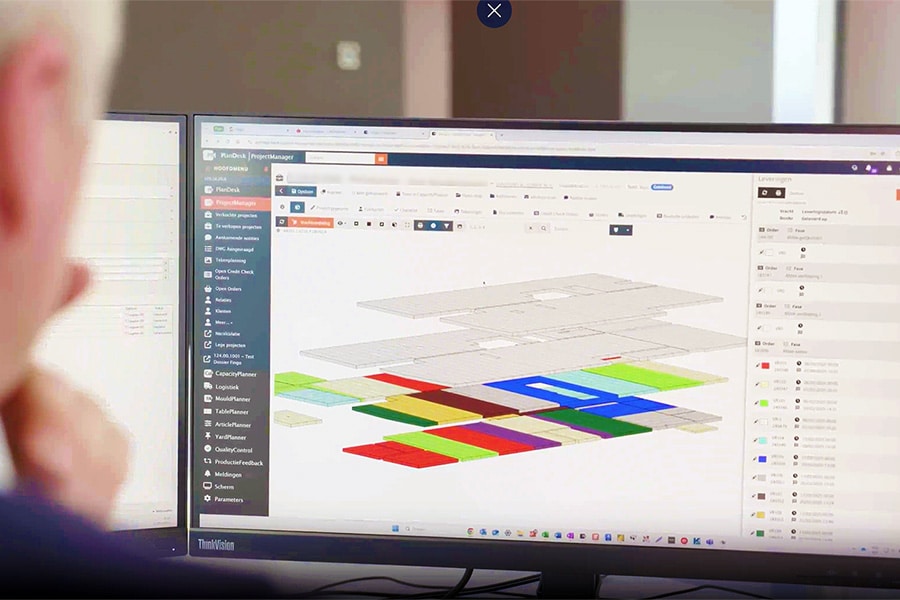

At Fingo, all phases of production are software linked, like an all-encompassing nervous system. As a result, data only needs to be entered once, the turnaround time shortens considerably, and the concept of a completely paperless office is taking shape. At the same time, the risk of errors and production losses is greatly reduced.

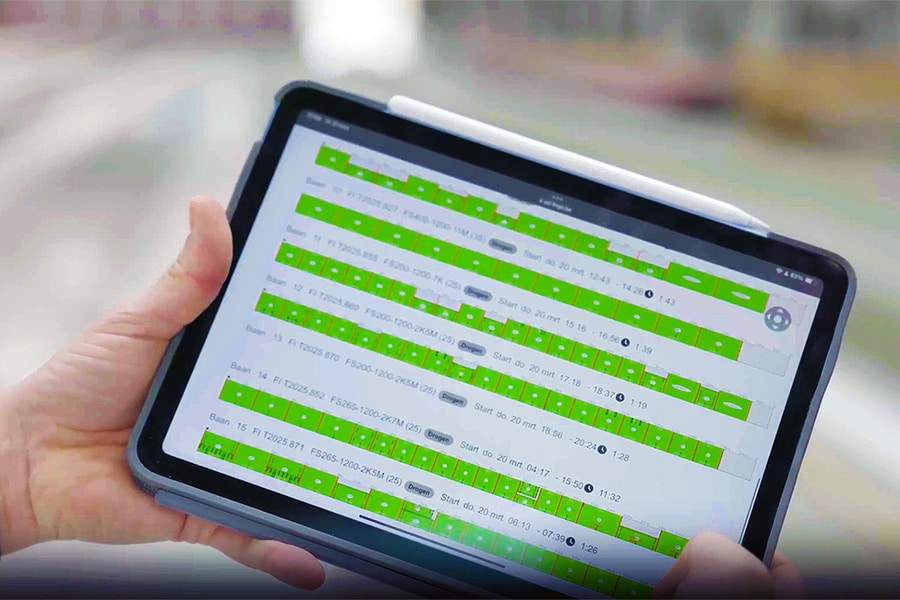

Rony Verlee, business manager at i-Theses: “Fingo uses both AutoFloor and PlanDesk modules, which together enable a smooth and manageable production flow. Specifically, these are PreCastOffice with ProjectManager for project management and follow-up, CapacityPlanner for reservations, production planning and quality control and a logistics module for chartering, delivery and stock management. This combination provides complete automation of management, design and production and guarantees a seamless exchange of crucial data with the production machines.”

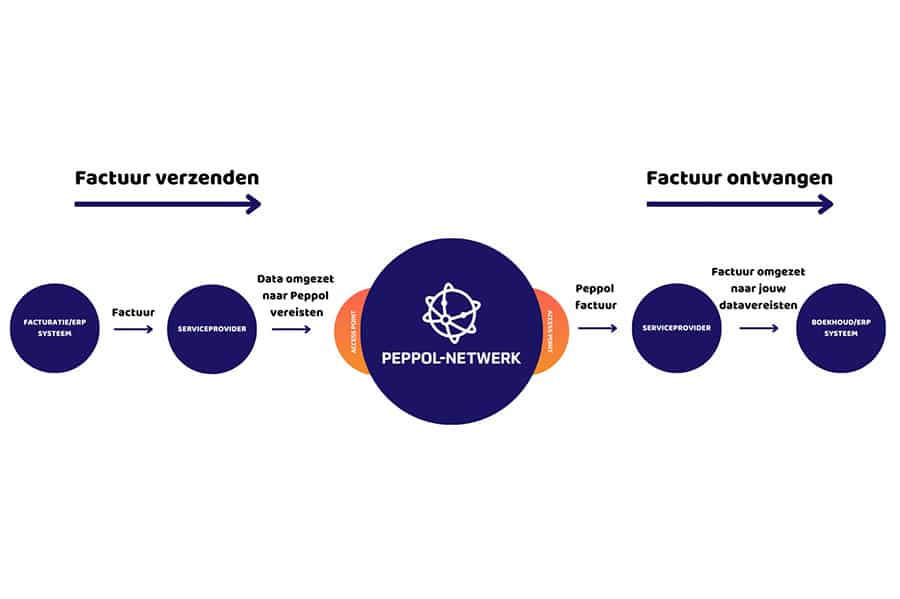

In addition, many PlanDesk applications are already web-based, allowing work to be done on any device, at any location and at any time. “The cooperation with Fingo is continuous and based on regular feedback, allowing for a quick response to new needs. For accounting, Fingo uses a separate system that is automatically fed with export files from our software. Some time ago, the ‘Yardplanner’ module was added. This digitally controls stock management with location, which used to be done on paper.”

Also noteworthy is the recent robotization with full feedback, which among other things allows automatic sawing to the correct dimensions. “And numerous finishing operations are now also robotically controlled. The feedback also allows incorrectly produced elements to be automatically remade with minimal loss of time. Everything takes place within a constant dialogue between Fingo, machine builder Nordimpianti and i-Theses.”

Sustainable approach

Fingo found in i-Theses an experienced and reliable partner for the digital optimization of its processes. i-Theses has been developing PreCastOffice, the leading software for the design of precast elements in reinforced and prestressed concrete and the automation of related business processes, for more than 25 years. Today, i-Theses' BIM, CAD and planning solutions are used by leading precast concrete producers in more than twenty countries.

In addition to digitalization, Fingo also invests heavily in sustainability. For example, the company has its own wind turbine and obtained, among other things, the Silver CSC certificate for sustainable and responsible concrete production, zero-loss status, BREEAM recognition and ISO 14001 certification. Thanks to this focus and working methodology, managing director Gert Van Cauwenbergh was named Antwerp Young Entrepreneur of the Year in 2021.

Further expansion in the Netherlands

To serve the Dutch market even better, a production plant with a capacity of 900,000 square meters is under construction. The new plant is being built in Hardenberg and will soon keep transport lines with Dutch customers as short as possible. A better national distribution leads to fewer kilometers driven, thus also lower costs and less CO2 emissions.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met i-Theses.

Contact opnemen

Contact opnemen