Dutch rebar workers choose Belgian software

Kresoft Systems, the software and automation company owned by Gert Janssens, has been part of the i-Theses Group since last year. Among other things, the company gained international fame with its targeted ERP total solutions for optimizing business processes at rebar processors. Together with i-Theses, it offers integrated solutions for the broader concrete sector, including concrete builders and producers of precast concrete elements. We polled some Dutch customers about their experiences.

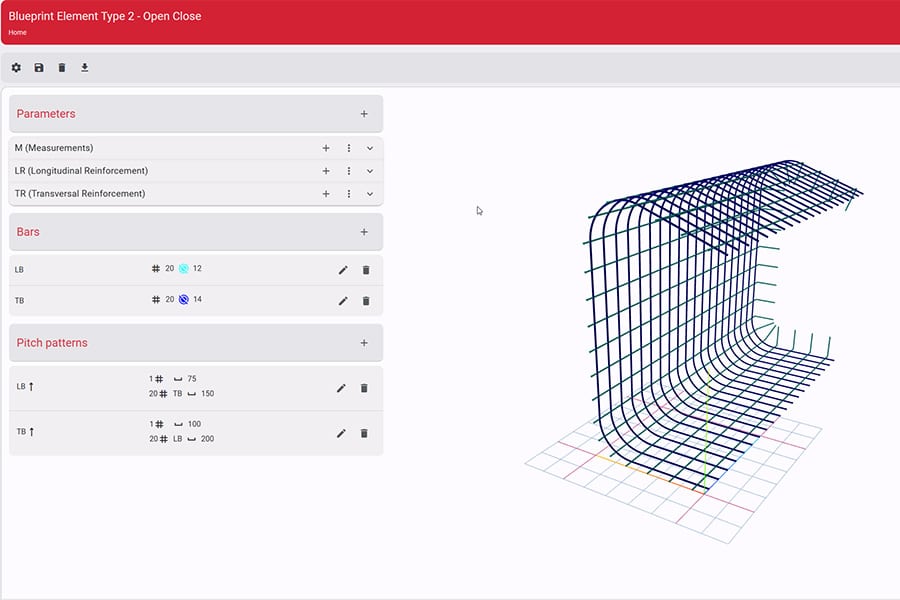

Reinforcement steel processing was "the missing link" in i-Theses' PlanDesk offering to support the entire process for the production of precast concrete elements. With Stargon from Kresoft, this has been fulfilled.

Flexibility was decisive

Augustinus Prefabwapeningsstaal BV from Ochten in Gelderland is part of the umbrella Augustinus Group, with branches in the rental of concrete pumps, concrete construction and concrete floors. The group converts some 150,000 tons of steel annually. The Precast Reinforcing Steel Division delivers reinforcements on more than one hundred projects every day. Its customers are spread across bending plants, braiders, construction markets, web shops and concrete builders.

It is also important that Augustinus BV floats on service, customization, innovation and energy-neutral entrepreneurship. Witness to this is its electrified machinery, powered by its own solar panels. Manager Jan Keuken: "Due to our large number of customers and numerous daily deliveries, we started using ERP Stargon from Kresoft in 2018. The transport planning and mobile Stargon App play an increasingly important role in this. Meanwhile, Kresoft has become a reliable long-term partner. It was able to seamlessly integrate its Stargon ERP system into our business processes to create a conclusive and comprehensive system - from purchasing to quotation, order processing, planning, production, logistics and invoicing. The flexibility and ease with which Stargon could be fitted into our own, existing procedures was critical in choosing Kresoft."

Sustainable and forward-looking cooperation

For more than 60 years, the Balvert Group from Nieuwkoop has been a cast-iron name in the Dutch construction industry. What once began as a driven family business has grown into a leading player in rebar solutions. Under the banner of Balvert Betonstaal BV and Balvert Vlechtwerken BV, the company delivers top performance daily in cut and bent rebar, prefab reinforcement, structural steel mesh and support beams. Yet Balvert's strength remains rooted in its familiar values: a no-nonsense mentality, short lines and a personal approach. Whether it comes to residential construction, utility projects, industrial buildings or infrastructure works: contractors count on Balvert for quality and proper execution on the building site. Cutting, bending, welding, delivery and processing: everything is done with extreme precision and craftsmanship.

Innovation and quality go hand in hand. In 2024, Balvert was the first in the Netherlands to obtain the KOMO product certificate based on the BRL 0507 - the ultimate proof of quality, safety and reliability in braiding technology. To continue this growth and innovation, Balvert chose a strategic partnership with Kresoft over fourteen years ago. The switch to the ERP system Stargon was a big step forward. Co-owner Conny Balvert: "With Stargon, we have one powerful, integrated system that supports our entire process: from purchasing and inventory management to quotation, order, production, delivery, and invoicing. Everything runs seamlessly together. That gives us overview, control and maximum efficiency. Exactly what you need in a dynamic sector like ours."

Thanks to Stargon, Balvert not only optimizes its internal processes, but also effectively prevents waste of time and materials. And at least as important: the cooperation with Kresoft is one of thinking along, moving along and continuously improving. Together, they are building a future-proof organization.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met i-Theses.

Contact opnemen

Contact opnemen