From digital invoices to chain-oriented process optimization

Ever stricter rules, ever greater pressure

The administrative burden in the construction and steel construction sector is increasing. Governments are imposing ever stricter requirements, margins are under pressure, and at the same time there is a growing need for better control over projects and processes. In this context, Peppol is no longer a topic for the future, but an immediate reality. Since 2024, Belgian companies have been required to send their invoices to governments (B2G) via the Peppol network. From January 1, 2026, this obligation will be extended to all business invoicing between companies (B2B). A similar regulation is also planned in the Netherlands, with a deadline of 2030.

However, Peppol is about more than just complying with regulations. According to Jan van Hapert of Liemar, there is a broader opportunity here. “Peppol is not an IT project,” he says. “It is the first step toward an administrative structure that should be as predictable and reliable as your production process.” Maarten Van Goethem of Nymus also sees the legal obligation primarily as an opportunity to work smarter in a structural way. “The great thing about Peppol is that it forces you to recalibrate your processes. Companies often invest in software for production, but not in their administration, even though there are huge gains to be made there: fewer errors, faster turnaround times, and real-time insight.”

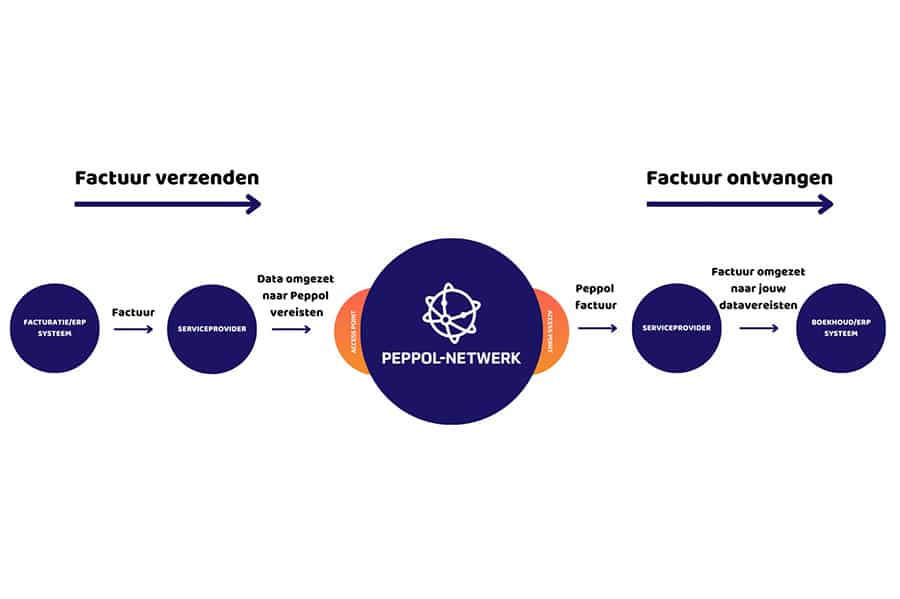

Access Points

The idea behind Peppol is simple: companies send and receive invoices via a secure network of recognized Access Points, in a uniform format (UBL). But the real value comes when the system is properly integrated into existing business processes. “Our customers want to know whether their specific situation will work,” says Van Hapert. “With progress reports, approval flows, different VAT rates—all these exceptions can be easily supported within Peppol, provided you set it up smartly. That's exactly why we work with Nymus.”

Van Goethem adds that standard solutions often fall short in practice, especially in steel construction. “Steel construction is not a standard sector,” he says. “Invoices are often large, linked to multiple projects or phases. Generic access points lack that nuance. That is why we tailor our infrastructure specifically to partners such as Liemar, focusing on the entire process: from UBL structure to correct receipt and processing.”

Cooperation as a foundation

This collaboration has been deliberately constructed. Liemar ensures the correct data delivery from the ERP system, while Nymus takes care of the transmission, validation, and linking to accounting and administration. Van Hapert: “Our philosophy is that your administration should be as streamlined as your factory. And that starts with collaboration. No separate tools, but chains that communicate with each other.”

That chain starts with proper implementation, explains Van Hapert. “But it has to be one that is so logical that users hardly have to think about it.” According to him, the strength of Peppol in Liemar is that it fits in completely with existing processes. “You activate it once, and from that moment on, everything connects automatically. VAT codes are linked to the correct standards in the background, and you send your sales invoices just as you always have – only now with a single click via Peppol. Incoming invoices are automatically retrieved and linked to the correct supplier, including all attachments and data. It goes straight to the right place in your administration, without any extra work or manual steps.”

The benefits only become truly apparent when they are put into practice. According to Van Goethem, that is exactly what is happening with customers. “We hear from customers that their processing time is drastically reduced. No more lost invoices and no more typing errors. Everything is guaranteed to arrive and is immediately available. That creates peace of mind in the workplace.” Van Hapert also sees this change. “That's exactly the difference we're trying to make visible. We remove the complexity so that our customers can focus on their core tasks.”

Everything automatically in its place

Attachments such as order forms or certificates can simply be sent along with the invoice, and attachments are also automatically imported for incoming invoices. Data such as item lines, cost types, and order information are automatically filled in, provided they are included in the UBL. Even in the event of error messages, the process remains simple: an invoice can be resubmitted directly from Liemar or via the Nymus portal. Customers always retain control over the approval process; rejection, correction, and crediting are fully supported.

Beyond invoicing

Peppol is just the beginning. In 2028, Belgium will take the next step: e-reporting, or automatic VAT reporting via the same network. Nymus is actively involved in European pilots such as the VIDA program and shares insights from these projects with partners such as Liemar. “We don't want to wait until something becomes mandatory to get involved, we want to be ahead of the curve,” says Van Goethem. “Because we believe that digitization is not a series of isolated interventions, but a continuous chain development.” Peppol is therefore not an end point, but a foundation. Those who invest now in a well-designed, sector-specific solution will build clarity, security, and process reliability, with less manual work and more control over the figures.

This article is based on insights from the webinar ‘Peppol in practice’ and the second webinar on technical implementation, organized by Liemar, Nymus, and InfoSteel.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Liemar Software BV.

Contact opnemen

Contact opnemen