How integrated software reduces risks and costs on the construction site

In construction, time is literally money, and foundation failures are the most costly in this regard. The critical interface where steel frames meet the concrete foundation - the assembly of footings and anchor bolts - has been a major risk point for many years.

A design error can lead to costly delays, last minute adjustments and even safety issues. Traditionally, the design of these connections was a fragmented and slow process, making it a bottleneck that could disrupt the entire project schedule.

Efficient and accurate

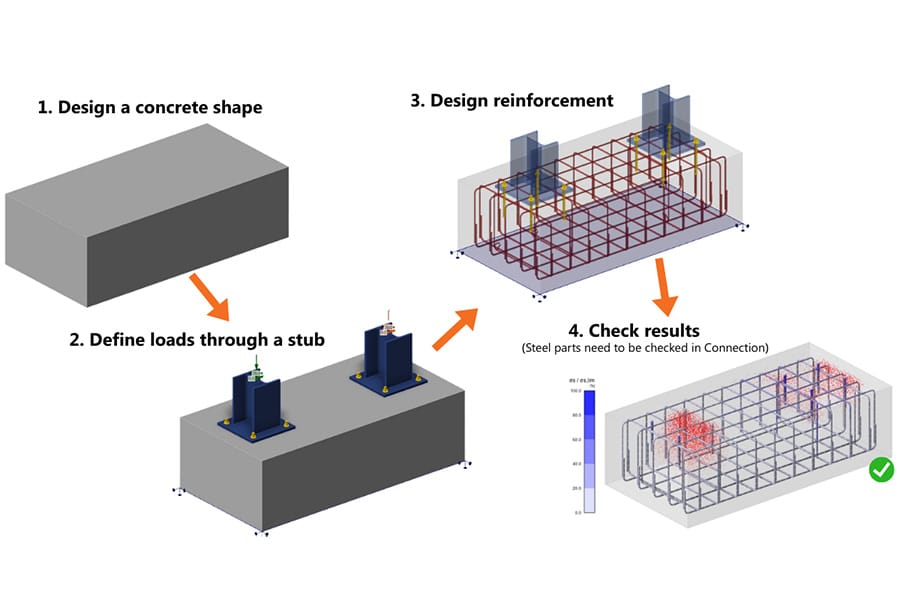

Now, an integrated software solution streamlines this process and construction companies benefit from a direct path to greater predictability and profitability. By unifying both steel and concrete design within a single platform, this approach eliminates the distance between different design directions. The workflow is designed for efficiency and accuracy. The system begins with analysis of the steel connection and uses advanced methods to model real-world forces. It then automatically checks the concrete for failure mechanisms according to international standards. Immediate detection of problems - such as a possible concrete failure near an edge - is an important tool for reducing risk. It catches problems in the office, not on the construction site when the concrete mixer is already waiting.

Manageable design task

The most powerful feature for construction teams is what happens next. Instead of triggering days of redesign, a single click exports the entire model to a reinforced concrete module. Here, engineers can visually design the reinforcement needed to solve the problem, while the software demonstrates how the reinforcing steel makes the connection safe. This turns a potential project shutdown problem into a manageable design task of minutes instead of days.

Uniform and standards-compliant approach

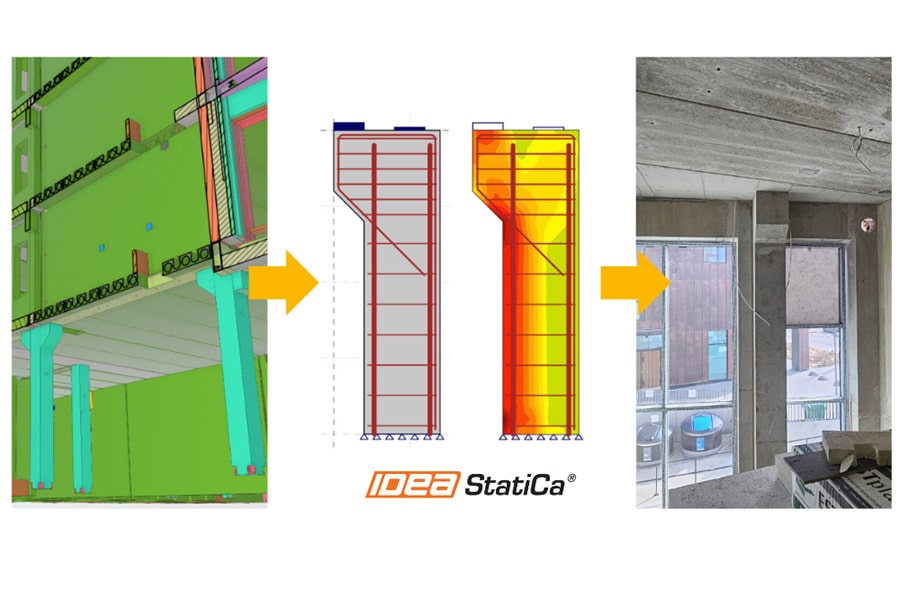

For steel-concrete connections, the platform's capabilities are a boon for engineers working with reinforced and precast concrete and dealing with complex areas of discontinuity. The same advanced calculation method reliably handles mundane challenges such as consoles (corbels) and tooth supports (dapped ends), as well as elements such as walls with openings, deep beams and wall beams. This provides a uniform and standards-compliant approach to a wide range of structural issues, standardizing quality and safety throughout the project.

The business value is clear: According to reports, this integrated workflow reduces design time for complex connections by more than 80%. This directly accelerates project planning and reduces engineering costs. In addition, visually demonstrating standards compliance provides definitive documentation that protects the company in the event of litigation.

Promotional Award

Recognizing that robust tools must be accessible, this complete, unified solution is currently available for a surprisingly low investment. Through December 25, 2025, obtaining the full lifetime license costs only 300 euros more than a single license for steel. For any construction company regularly faced with the costly challenge of steel-concrete connections, this represents a significant opportunity to make projects less risky and more efficient.

For construction companies, this is not just about better software, but a smarter business model. By ensuring connections are designed right the first time, they can avoid costly delays, reduce material waste through optimization and build a reputation for delivering projects safely and reliably on schedule.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met IDEA StatiCa BeNeLux B.V..

Contact opnemen

Contact opnemen