Increasing automation with software and machines

Improving production efficiency

Founded in 2008, Comines Steel has become a market leader in the automated production of concrete reinforcement. To maintain its competitive advantage in Belgium, the Netherlands, France and the United Kingdom, the company has made significant investments in software and machinery to improve efficiency, transparency and flexibility.

Strategic investments in machinery

Comines Steel works closely with the Progress Group and has four specialized M-System machines in operation, including three mesh welding units for rebar mats with automatic bending system and a Power Mesh high-efficiency mesh welding unit for rebar mats. This recent upgrade further improves rebar mat production, increasing both speed and volume capacity. This ensures that the company can meet growing market demand without difficulty. "We believe in staying at the forefront of automation," said Olivier Herpoelaert, owner of Comines Steel. "By upgrading our machinery, we can better serve our customers with faster production times and higher precision."

To further expand its automation capabilities, Comines Steel has also integrated a multifunction Pluristar machine and an EBA bracket bender from the Progress Group into its machinery fleet. These machines improve the processing of loose rebar, allowing the company to offer a wider range of services to its customers while maintaining high efficiency.

Software for optimized productivity

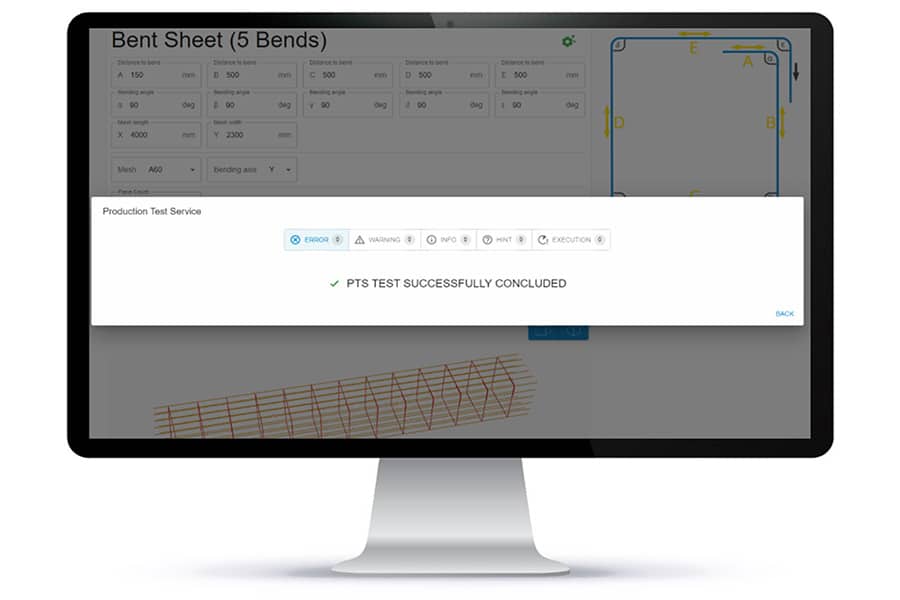

Six office workers use profit YC and stabos Pro daily to manage orders, adjust production settings and schedule deliveries in real time. Previously, the company relied on an outdated version of profit, which limited clarity and flexibility. With the upgrade, production can be tracked in a streamlined way, real-time status updates are available, and last-minute changes can be handled efficiently. This makes for smoother work processes and allows for better responsiveness to customer needs. "The new software upgrade has completely changed our work processes," says Herpoelaert. "We now have full insight into our production, allowing us to make better decisions and increase efficiency."

Comines Steel's entire production is managed by profit YC, which integrates key machines such as the M-System mesh welding systems for rebar mats, double bending systems, EBA stirrup bender and a multi-purpose Pluristar machine, as well as a Shearline from a third-party machine supplier. This seamless integration enables optimized production planning, accurate machine allocation and improved operational efficiency.

Strong cooperation

A key benefit of working with the Progress Group is the seamless integration between software and machines. The ability to centrally control all machines, dynamically allocate production orders and receive valuable insights into productivity has significantly optimized business operations. And with a dedicated software engineer familiar with Comines Steel's work processes, any technical issues are quickly resolved, ensuring uninterrupted production. "Progress Group is a reliable partner for us," says Herpoelaert. "Its expertise and commitment to innovation align perfectly with our vision of automation and digitalization."

Vision of the future: embracing digitization

Comines Steel plans even further steps in the area of automation and digitalization. The company is convinced that a fully integrated ERP package, linked to profit YC and stabos Pro and together with modules for planning and logistics will provide even more control and efficiency in production. By investing in pioneering technology and maintaining strong industrial partnerships, Comines Steel is fully committed to innovation and optimization of production processes, ensuring long-term success in the rebar industry.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met PROGRESS GROUP.

Contact opnemen

Contact opnemen