Knowledge session lean in steel and metal - key findings

On September 11, together with Infosteel, Indus, Modulyss, Vytech and Meco Metal, we organized a knowledge session on Lean in steel and metal. It became an energetic afternoon and evening in which practical examples, inspiring insights and especially a hands-on workshop by Indus were central.

Experiencing Lean in practice

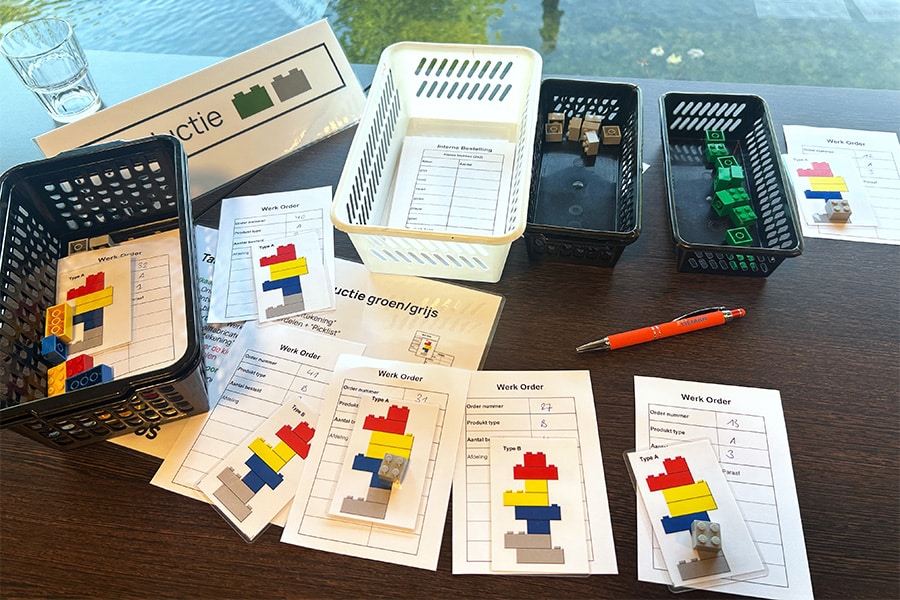

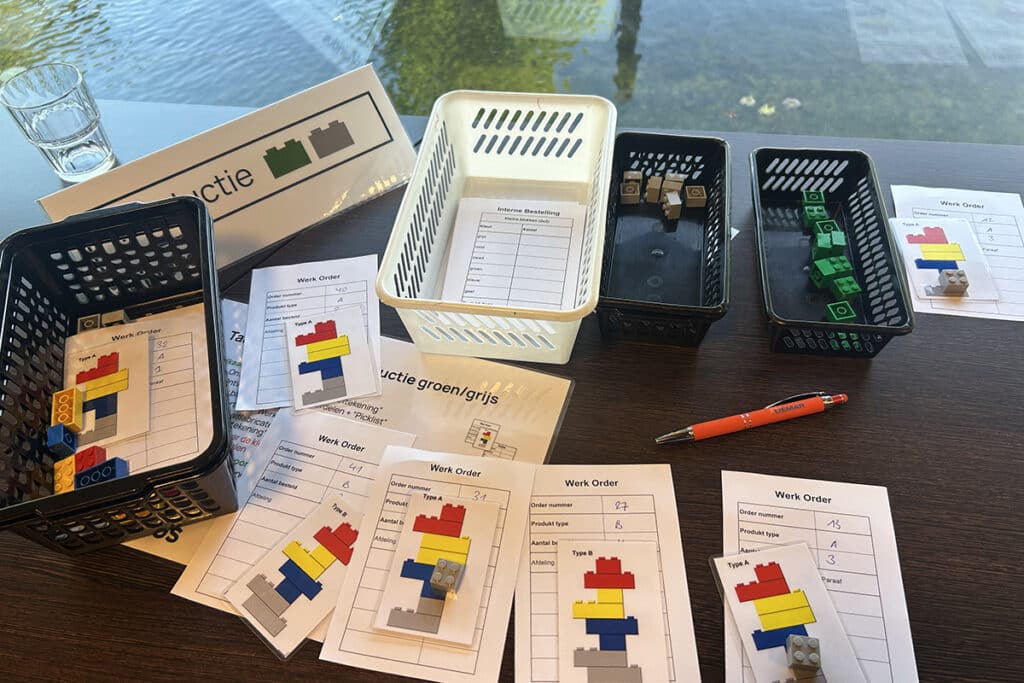

The main focus of the evening was the interactive Lego workshop by Indus. In this exercise, participants got to work with lean themselves. Not by listening or watching, but by doing it themselves. The dynamic that arose was contagious: even participants who were initially a bit hesitant quickly became involved and enthusiastic. The strength of the workshop was that the principles of lean became immediately visible. Inefficiencies came to the surface, improvements could be tested on the spot and the translation to one's own work practice became obvious. Afterwards, the reactions were unanimously positive: this was instructive, motivating and, above all, concretely applicable.

Inspiring stories as context

Around the workshop, several companies shared their experiences with lean, each from their own perspective. Modulyss showed how they achieved structural improvements through years of machine optimization. Their story emphasized the value of a clear plan and sticking to a long-term strategy. Vytech showed precisely the power of support in implementation: they made it clear that a change only succeeds when planning, guidance and support are well organized. Finally Meco Metal an inside look at how lean can become an employee-centered culture. Their approach is all about ownership and continuous improvement, even when things are tough.

Together, these stories provided valuable context for the workshop. They made it clear that lean has many faces - from machines to people - and that there is no one right way to go about it.

Key insights

What stuck is that lean is primarily about experiencing and doing. The workshop made it clear how processes can be set up smarter and how quickly improvements become visible. At the same time it became clear that lean always requires customization: for some the profit lies in machines, for others in culture and employees. Successful realization requires more than just a good idea; without a plan, planning and support, improvements will stall. And perhaps the most important insight: lean is never finished. It is a continuous process that keeps evolving.

Valuable energy

What made the evening so valuable was the mix: an inspiring exercise, stories from practice and a group of participants who actively participated and exchanged experiences. The energy in the room was palpable and afterwards there was a broad desire to continue with the insights gained, also within the own organization.

Conclusion

The knowledge session made it clear that lean only really comes to life when you experience it for yourself. Indus' workshop formed the heart of the knowledge session, supported by inspiring practical examples from Modulyss, Vytech and Meco Metal. Together they showed that lean is not a standard recipe, but a journey that you take step by step and together with your people.

Would you also like to organize a session where theory and practice come together? Feel free to contact us - we are happy to facilitate this.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Liemar Software BV.

Contact opnemen

Contact opnemen