Lamgat bridge: circular prefabricated project with 82% reclaimed steel

The Lamgatsebrug is an important connection between the municipalities of Moerdijk and Halderberge. Due to wood rot and its 40-year age, this pedestrian and bicycle bridge was in need of replacement. Bridge builder Meerdink Bruggen modeled and prefabricated the new Lamgatsebrug, using old parts of a railroad bridge. The bridge was installed in 2024.

The Lamgatse bridge has been a replacement task of the municipalities of Moederdijk and Halderberge. The bridge is right on the municipal boundary. “In the spring of 2023, the municipality came to us asking if we wanted to participate in the tender, where the circular component was very important,” says Robbert de Metter, owner of Meerdink Bridges. “We thought about an efficient design for the existing bridge structure. The new design was 92 meters long with a free span of 55 meters. We chose the same bridge type: a pylon bridge.”

Building circularly with used steel

If you want to build circularly, the available material is the starting point. From the client, there was only one requirement for the replacement design: no wooden bridge. De Metter: “In a circular construction project, you have a certain material available. In this project, that was used steel. We acquired a large batch of steel from ProRail two years before the tender for the Lamgat Bridge. They wanted the material to be reused and with the bridge we found a good way to do this.” Paul Beijers, draftsman at Meerdink Bridges: “Working with reused materials meant that we had to carefully map out what we were drawing. The new situation naturally had to fit in with the old situation. In the end, we were able to reuse the full-length steel from ProRail for the new bridge.” With these 24 meters of HEA550 steel profiles in stock, the drawing process began.

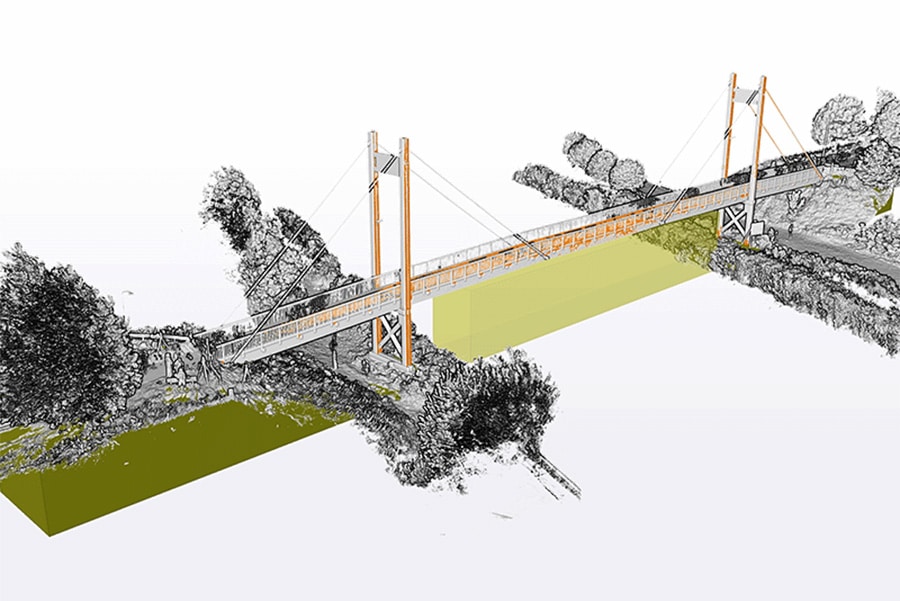

Data retrieval with a point cloud

“First, we made a point cloud of the old bridge,” says Beijers. “This allowed us to measure the old bridge exactly with all the dimensions, so that the new bridge would fit back in place and connect properly to the existing concrete foundation.” The point cloud formed the basis for the new pylon bridge. “With the lines, we set up the 3D model and started modeling in Tekla Structures.”

Modeling with circular material

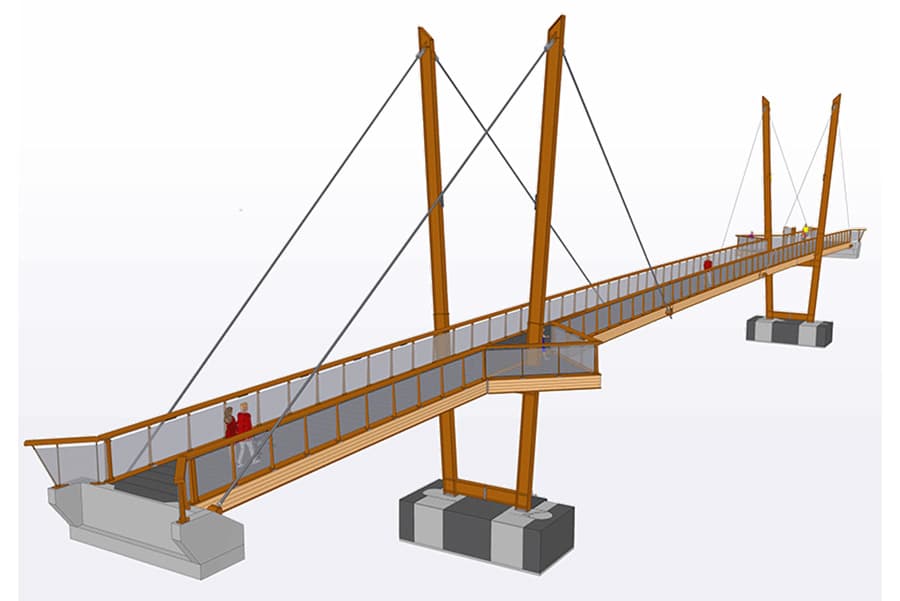

The bridge with two pylons consists of two welded railroad bridge sections. Beijers: “We drew all the parts in Tekla Structures, made all the working drawings and directed the assembly. We also modeled details, such as smart animal-friendly LED lighting in the bridge, for extra safety. When a cyclist leaves the bridge, the light dims.”

Cooperation with subcontractors and municipality

The cloud platform Trimble Connect played an important role in working with subcontractors. Says Beijers, “Trimble Connect allowed us to discuss details one-on-one with our subcontractors and point out situations where something needed to be done. We also used the program to visualize the project for our client in order to include him in the process.”

Super-smooth installation through prefabrication

Meerdink Bruggen placed the prefabricated pedestrian and bicycle bridge within a few days. Beijers: “We try to prefabricate as much as possible to keep the hours on construction as short as possible. The Lamgat bridge consisted of about seven parts. These parts were assembled in our factory and brought to the site. Within one week, the new bridge was ready for use.”

An inspiring example for circular bridge building

The replacement of the Lamgat Bridge is an inspiring example of how circular construction can transform our infrastructure. By giving new life to old material and working efficiently with innovative techniques, such as the point cloud and prefabricated parts, Meerdink Bridges has shown that sustainability and quality can go hand in hand. But circularity doesn't stop with this project. At the new Lamgatsebrug, you will find benches made from the old wood, while other bridge materials will be reused as jetties in Oudenbosch harbor.

Construction Info

architect

Arc2 Architects - Gert-Jan de Jong

client

Halderberge municipalities - Leo Kaan and

Municipality of Moerdijk - Arjan Deurloo

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Construsoft.

Contact opnemen

Contact opnemen