Software for manufacturing: The benefits of working with standards

Under the influence of BIM, exchange of digital data between construction partners has become almost a daily topic. Starting with the digital exchange of drawings, today it involves complete building models, including all relevant information for a specific construction partner. BIM is about people, processes and digitization and is only successful if all three aspects are well organized. The use of the right standards is essential for this.

Autodesk

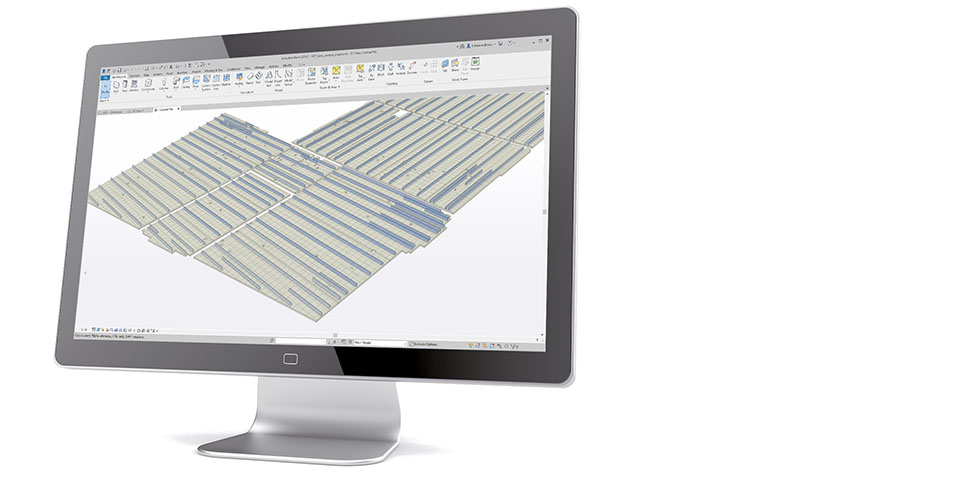

"We have strategically chosen to have our CAD/CAM solutions work closely with Autodesk software," said Heico Heuver, director of Matrix Software. "The most important products for this are AutoCAD and Revit. These are the CAD engines on which our concrete application IC-Prefab and steel application Advance Steel run." This choice is no easy one. Autodesk is the market leader when it comes to solutions for designers in construction. Architects, structural engineers, installers and construction companies work largely with Autodesk solutions. Matrix Software focuses on companies in building supply, such as frame factories, precast concrete factories and steel construction companies. Digital information exchange between designers and production companies is easiest when you use the same CAD applications. The IC-Prefab and Advance Steel applications make optimal use of this.

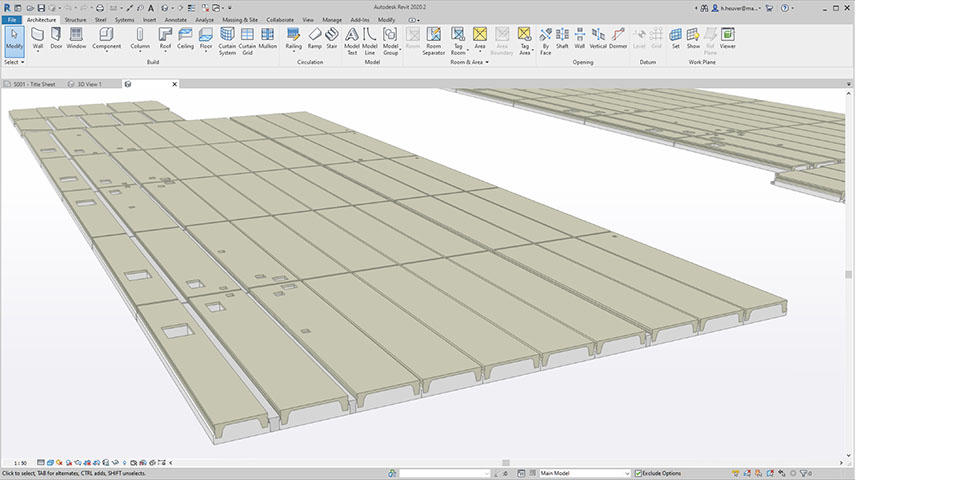

Screenshot of ribcassette.

BIM & ILS

Digital information exchange has taken off under the influence of BIM. The development of ILS, the Information Delivery Specification, has recently been followed up with ILS Design & Engineering (O&E). In this ILS, the description of specifications and procedures goes a step further. The ILS O&E also provides the ability to process and exchange performance requirements digitally. "Matrix Software has been working with its customers in project groups to implement the benefits of this new ILS O&E in the software," explains Heuver. "Our ambition is to further expand our leading position in construction supply with the best possibilities for digital information exchange. BIM is the catalyst for chain automation for us."

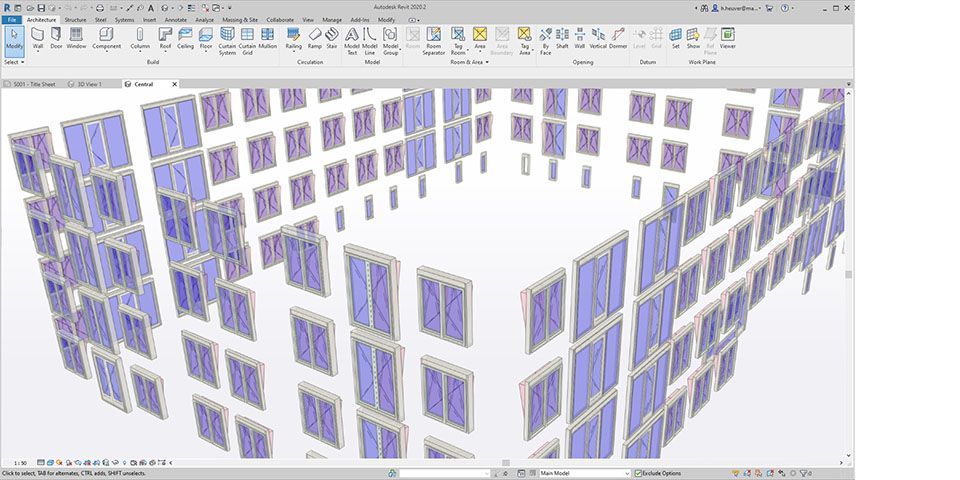

Screenshot frames.

Open standards

Matrix chooses above all to use open standards. For example, the standard EDI formats of the Chain Standard are used for orders, orders and invoices. A pilot is also underway within steel construction with data exchange between steel suppliers and steel construction companies, based on the same Chain Standard EDI formats. IFC has been chosen for exchanging building and production models. "In exporting data from our applications based on IFC, we can provide fine. It allows designers and builders to incorporate production models of concrete floors, frames and steel structures into their building and business processes," Heuver explains. "Processing IFC data at the front end of our applications still poses quite a challenge. The number of dialects is still quite diverse. For the time being, these are specially developed links, but I am convinced that it is just a matter of time that this too can be done via open standards."