More transparent, easily traceable and planable

Digital innovations for precast concrete element production

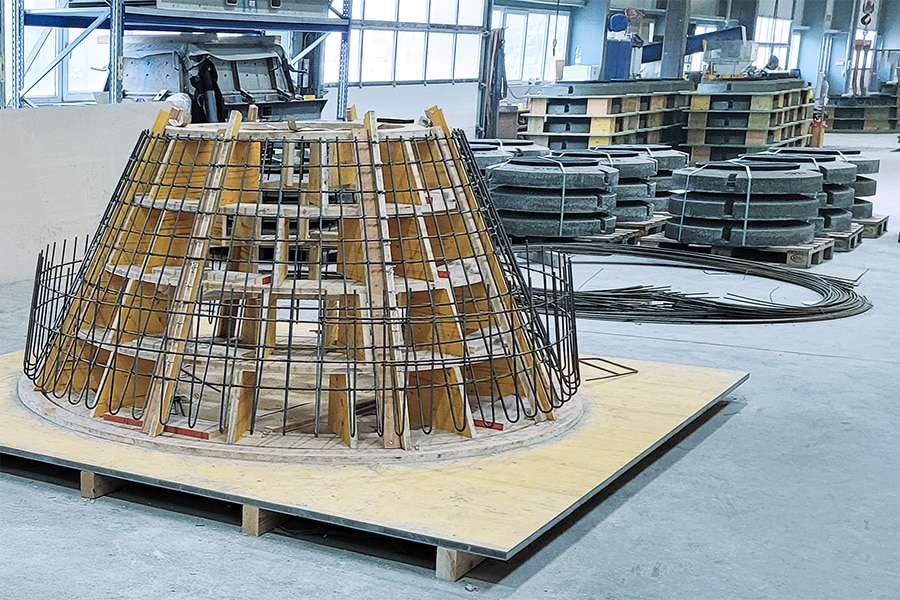

Since 1896, Baumat AG has stood for quality and reliability in the construction industry. The family-owned company - with its headquarters in Wichtrach and six other branches in the canton of Bern - offers a comprehensive range of building materials. In addition, Baumat AG specializes in customized reinforcing steel and the production of customized concrete elements. From stairs and facade elements to individual customized products. With the slogan ‘you build - we deliver,’ Baumat AG and its approximately two hundred employees support customers in carrying out construction activities qualitatively and on time. Both with a broad product range and appropriate consulting and planning services. Since October 2023, Baumat AG has been using the software solution ahead as a comprehensive solution, in order to make the growing production of precast concrete elements more transparent, easier to trace and more planable.

Software ahead as a total solution

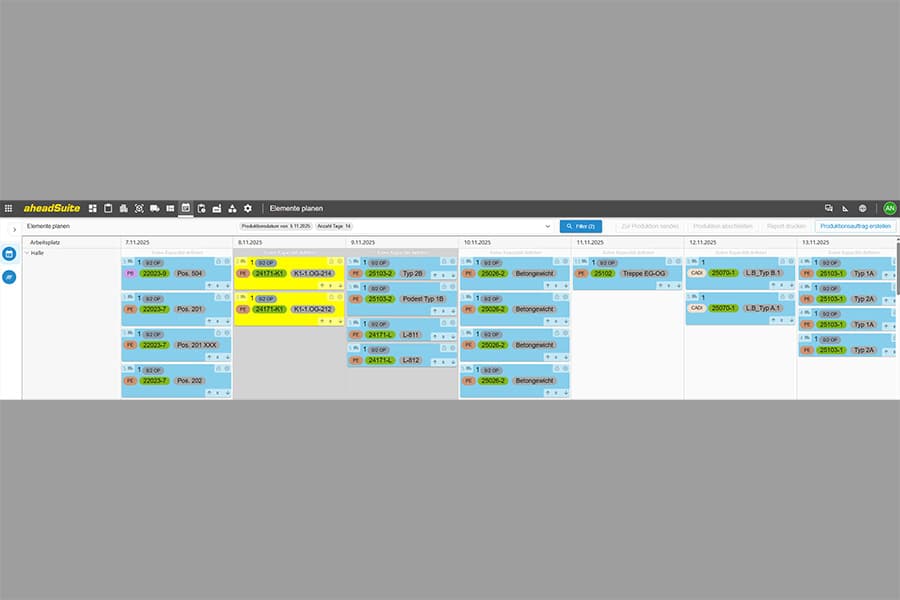

The prefabrication of concrete elements has grown steadily in recent years. However, with the current Excel planning, the increasing number of elements could no longer be charted. The goal was to replace the existing Excel-based processes with modern software, which could be integrated incrementally into ongoing operations and remained compatible with the ERP system and 3D modeling. The software ahead was chosen from Progress Group's software portfolio. The focus of the implementation was on displaying and integrating all relevant areas: production, quality, planning and logistics.

A core team of five employees coordinated the project, while approximately 40 employees used ahead throughout the value chain. During the transition, two systems were used in parallel and individual processes were migrated to ahead step-by-step, accompanied by extensive training. “Because we wanted to use ahead productively as quickly as possible, some development steps and adjustments did not take place until after the go-live,” says Thomas Kiener, production manager and member of the management board at Baumat AG.

Constructive and efficient

ahead was introduced as a central platform and connects production, quality control, planning and logistics. With ahead, order processing is considerably more transparent and coherent, partly due to the link to the existing ERP and 3D modeling software. This applies in both directions: from order entry in the ERP system and transfer to ahead to the feedback of the produced concrete

elements to the ERP system. As a result, Baumat AG now has a real-time view of order status. Even after the go-live, support from the project team remained great. Kiener: “The cooperation with the Progress Group project team was and is excellent. Rarely have I experienced such constructive and efficient cooperation within a software project.”

Transparent and process-oriented

“Order processing becomes much more transparent because of ahead. Every step can be followed in real time, from order acceptance to delivery,” said Kiener. “Quality assurance and traceability of the individual process steps also reach a new level. Every step can be documented, controlled and tracked in ahead. Not only during production, but also after delivery of the elements to the customer's construction site.” In the future, formwork production in the carpentry workshop will also be displayed in ahead in order to be able to coordinate production even more closely. “Only an integrated, data-based solution in parallel with operational business management can provide true end-to-end transparency, traceability and the

create necessary flexibility,” Kiener summarizes the benefits.

Looking to the future

The results at Baumat AG show how a traditional building materials company can strengthen its processes and at the same time future-proof them through targeted, partner-supervised software implementation. The roadmap further provides for the linking of a planning tool and an inventory management system and the gradual extension of the use of ahead to other sub-processes in production in order to jointly pursue a comprehensive digitization strategy.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Progress Software Development GmbH.

Contact opnemen

Contact opnemen