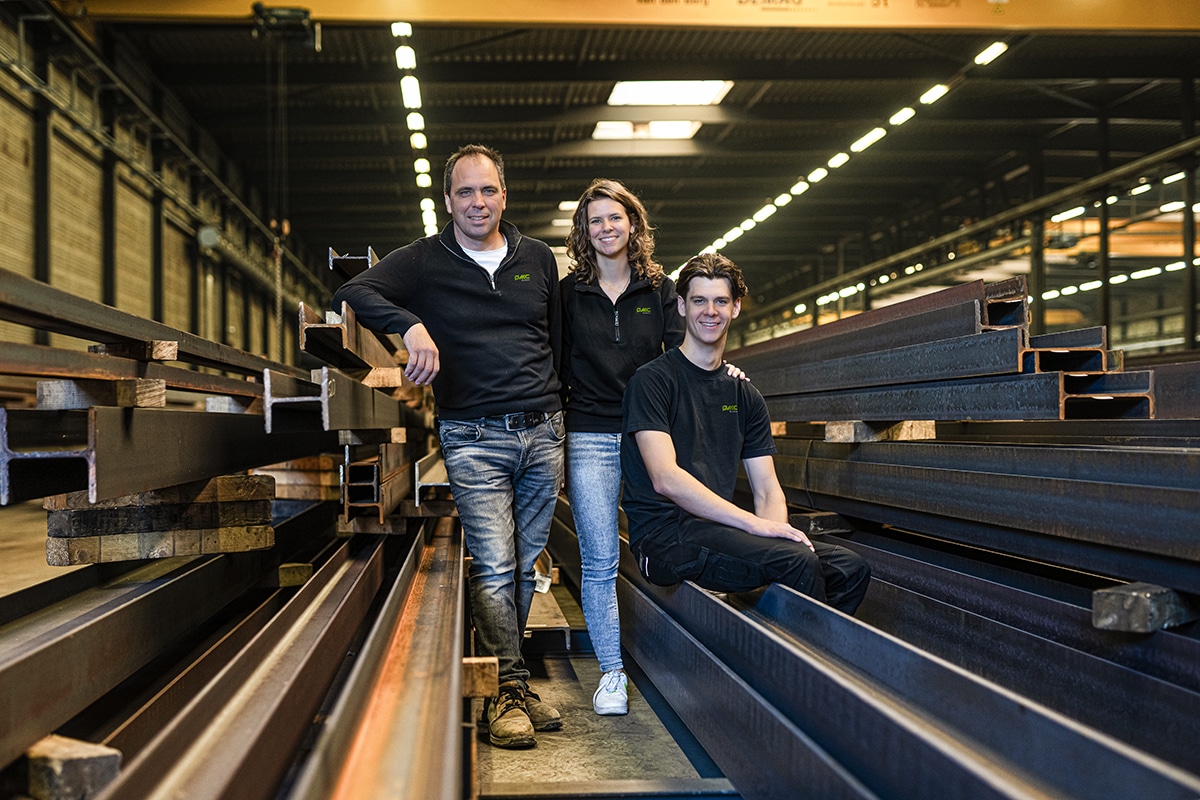

PMC Steel Construction is building for the future with the second generation

PMC Staalbouw has been producing steel structures for non-residential construction, the agricultural sector and equestrian buildings since 2003. Patrick Michels and his wife Suzan took over a small steel company - with one employee - and built an organization of several limited liability companies and a total of about 90 employees.

In recent years, the family business was strengthened with the second generation: daughter Lise in the office and son Geert in the workshop. With the influx of the second generation and a clear focus on automation and digitalization, the company is now working step by step on a future-proof organization. Not by changing everything at once, but by building together on sustainable improvements that are truly supported.

For Lise Michels, the move to PMC Steel Construction was not a matter of course, but a well-considered choice. ‘At home at the kitchen table, we used to talk a lot about the company: what do we want, who sees themselves working there later? It turned out that all three of us - including our sister Iris - were open to it.’ Still, it was important to gain experience outside PMC first. After studying Business Administration, Lise worked elsewhere before she decided to step in almost three years ago, with the intention of staying. ‘I haven't regretted that choice for a second.’

New generation, new dynamics

The arrival of the second generation was followed up when Geert also joined PMC, as workshop manager of the record hall. That brought new energy to the organization. ‘You notice that we are now really building together as one team,’ says Lise. With many young recruits, openness to new ideas and different ways of working is growing. Change does not happen by itself; it requires momentum and support. PMC seems to have reached that point now. ‘Projects are coming loose, employees are thinking along and the shared ambition to take steps forward can be felt throughout the company.’

At PMC, ‘team’ means everyone who works there. The course is coordinated with the managers; when changes occur at the departmental level, the employees are involved. ‘This is how we all try to move a step further together. This approach creates ownership and understanding and makes it easier for changes to actually land in practice.’

Digitization as a practical accelerator

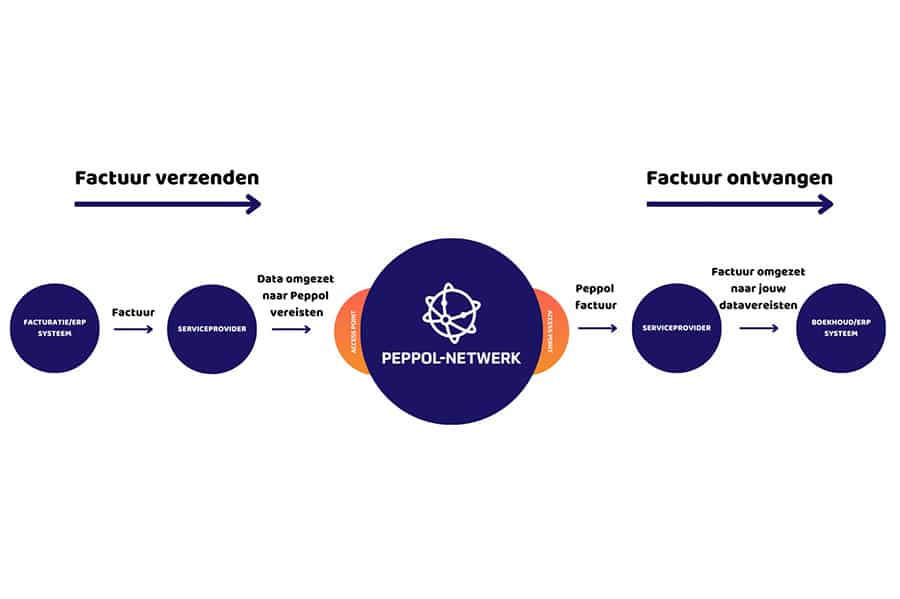

Firm steps are also being taken in the area of digitization. The arrival of new colleagues - often with experience in other systems - provides fresh insights. ‘That makes us think together: we really need to look at this. We don't see digitization as an end in itself, but as a means to make processes clearer and more efficient. In this we also like to work together with Liemar.’

An important example is the work preparation module, which is now being implemented. ‘When work preparation, production and invoice processing are well connected, the whole project runs smarter. This is also noticeable in the workshop. For example, Geert is no longer manually sorting drawings. If we do the work preparation in Liemar, Geert automatically gets a clear list. That saves a lot of time.’

The possibilities extend further. By reading drawings and 3D models directly from the drawing package, including all data, a fully digital routing through the company is created. Logistics flows are controlled centrally, where previously this was largely done manually. This creates a fully automated process.

Growing smarter within existing space

A possible next step is the development toward a digital workshop, in which employees work with tablets and paper drawings disappear from the halls. Processes such as time recording and quality information can also be optimized.

‘The available space is limited, so optimization is essential. By designing processes more efficiently, more production can pass through the same workshops. That requires continuous thinking about how things can be done smarter, faster and better.’

Future-proof, with an eye for people

‘We don't change headlong. We introduce new ways of working step by step, so that processes become permanent and people can and want to go along with them. But we still see many great opportunities for our organization.’

With the second generation on board, a clear view of the future and a focus on smart digitalization, PMC Steel Construction continues to build an organization that is ready for tomorrow.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Liemar Software BV.

Contact opnemen

Contact opnemen